Mounting method of artificial stone ceiling based on expanding nuts

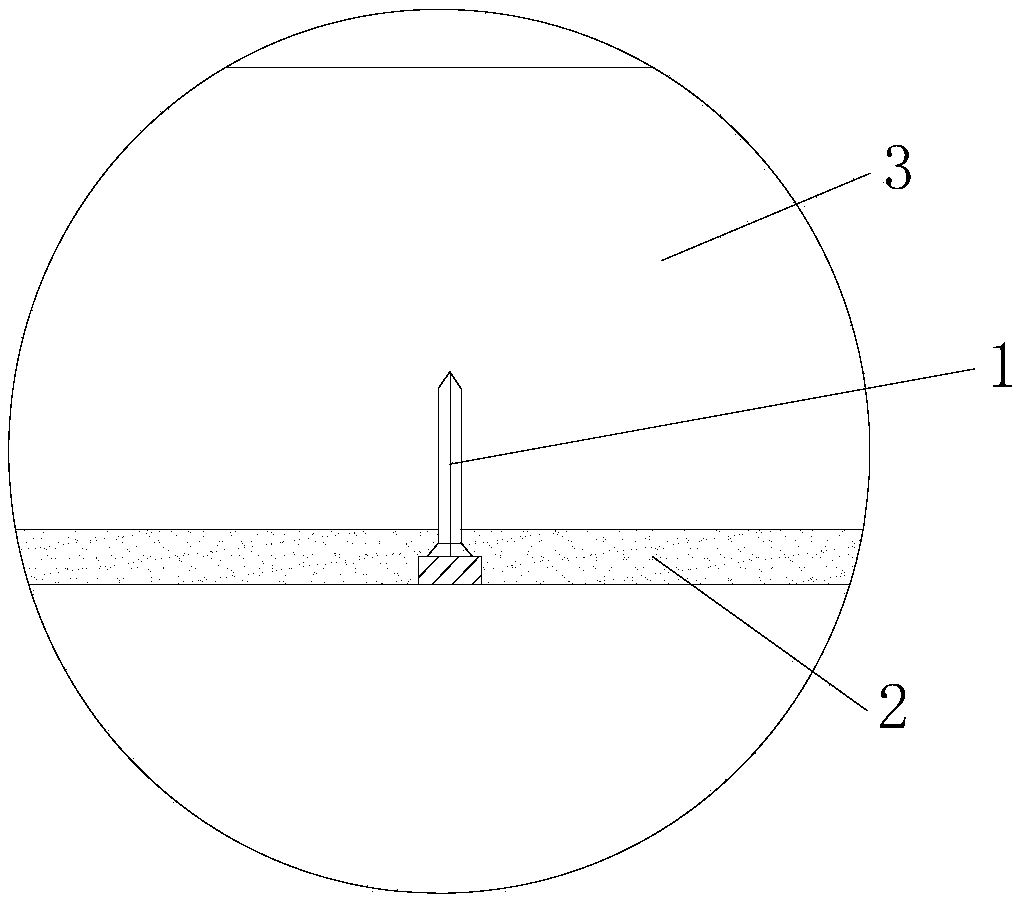

An installation method and artificial slate technology, applied in building structures, building components, buildings, etc., can solve the problems of plate surface installation defects, difficult repair and restoration, etc., and achieve the effect of expanding the decoration market field, low cost, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] This installation method for installing artificial stone ceilings based on expansion nuts is the same as Embodiment 1 except for the following technical features: the installation method for installing artificial stone ceilings based on expansion nuts, including the following steps:

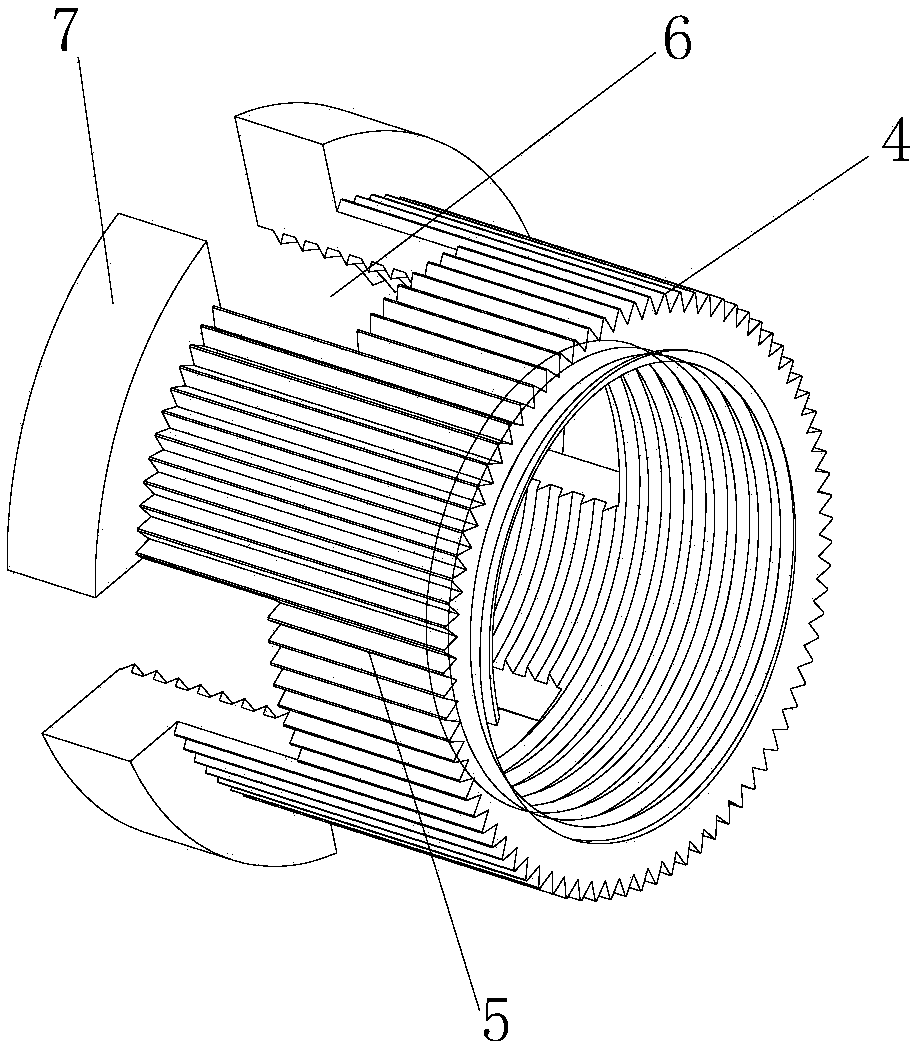

[0029] 1) Making expansion nuts: CNC machine tools are used to add blanks to make expansion nuts. The expansion nuts include a main body. The main body is cylindrical and has internal threads. One end of the main body is provided with an open groove, and the main body One end is provided with a block;

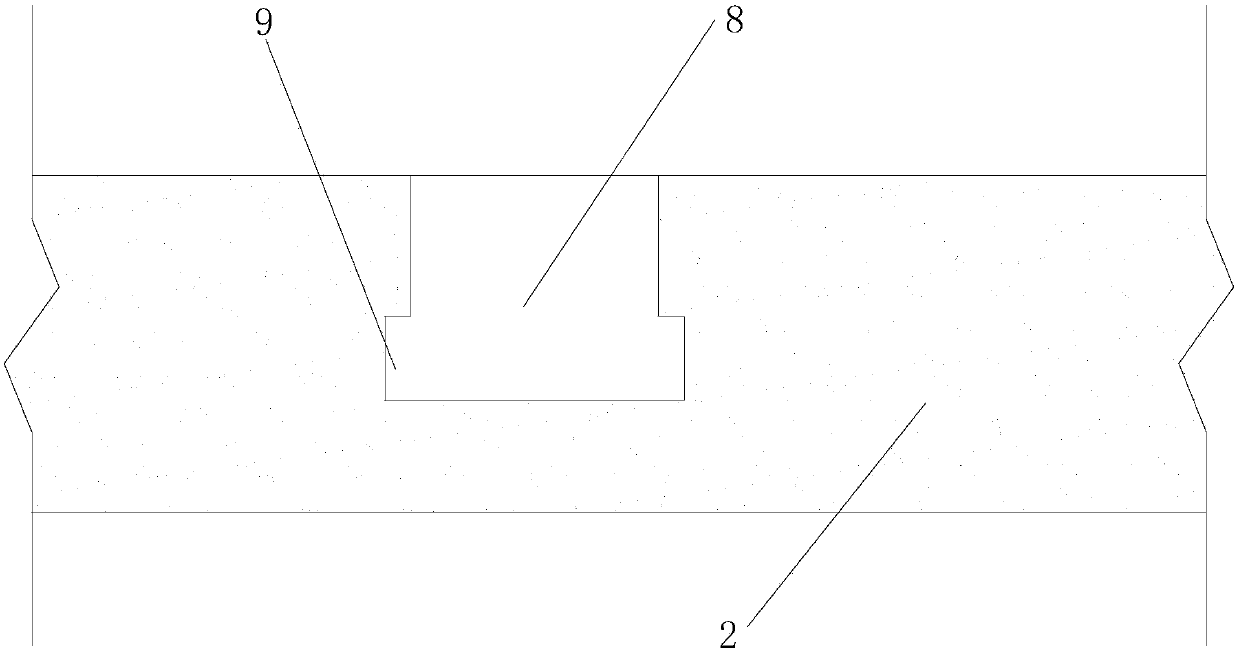

[0030] 2) Hole opening: Drill a counterbore with a diameter of 10mm and a depth of 9mm on the back of the artificial stone slab, and then use a slotting knife to mill the diameter of the bottom of the counterbore to 12mm to form a slot; to make the counterbore The outline matches the shape of the expansion nut;

[0031] 3) Fix the installation component: Make one end of the expansion nut, ...

Embodiment 3

[0034] This installation method for installing artificial stone ceilings based on expansion nuts is the same as Embodiment 1 except for the following technical features: the installation method for installing artificial stone ceilings based on expansion nuts, including the following steps:

[0035] 1) Making expansion nuts: CNC machine tools are used to add blanks to make expansion nuts. The expansion nuts include a main body. The main body is cylindrical and has internal threads. One end of the main body is provided with an open groove, and the main body One end is provided with a block;

[0036] 2) Hole opening: drill a counterbore with a diameter of 9mm and a depth of 7mm on the back of the artificial stone slab, and then use a slotting knife to mill the diameter of the bottom of the counterbore to 11mm to form a slot; to make the counterbore The outline matches the shape of the expansion nut;

[0037] 3) Fix the installation component: Make one end of the expansion nut, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com