Handle of oil-immersed fuse used for American-type box substation

An American-style box change and fuse technology, applied in the field of handles, can solve the problems of potential safety hazards, inability to extend the insulation distance, and poor sealing performance, so as to increase the sealing performance, improve performance, and meet the requirements of operating strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

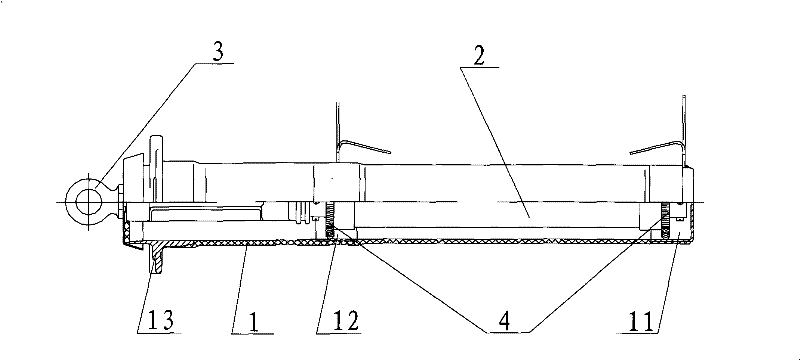

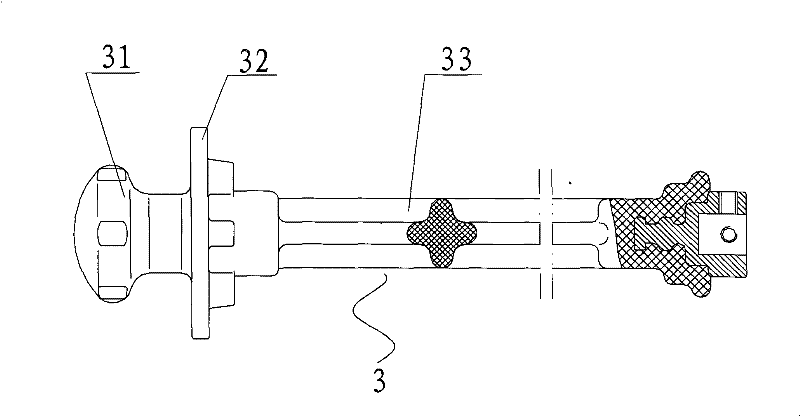

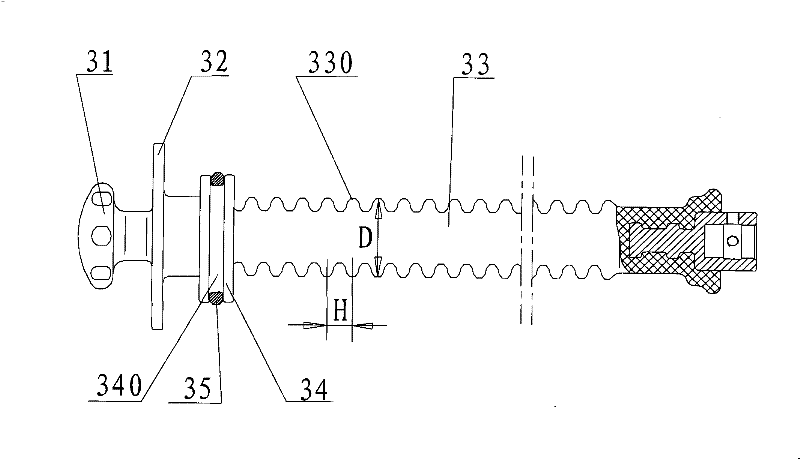

[0014] see image 3 , the handle 3 used on the oil-immersed fuse of the American box transformer of the present invention includes a handle 31, a cover 32, a connecting rod 33, a sealing structure 34 and a sealing ring 35, wherein,

[0015] The connecting rod 33 , the cover 32 and the handle 31 are sequentially connected; the cross section of the connecting rod 33 is circular, and its outer peripheral surface is radially provided with multi-layer umbrella ribs 330 at intervals along the length direction. The diameter D of each layer of umbrella ribs 330 is equal, and the spacing distance H is also equal. The umbrella rib 330 protruding from the outer peripheral surface of the connecting rod 33 can increase the relative creepage distance of the fuse; Extending to the cylinder, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com