Internalized charging method for standby lead-acid battery

A lead-acid battery, charging method technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., to achieve the effect of high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A backup lead-acid storage battery internalization charging method, comprising the following steps: the storage battery filled with acid is placed in a circulating water bath for 5 minutes, the internal temperature of the battery is reduced to below 40°C, and the charging circuit of the storage battery is connected to prepare for charging. When the battery temperature is not higher than 40°C, turn on the charger for charging, specifically:

[0014] (1) at 0.03C 10 Charge for 5 hours; (2) then charge at 0.1C 10 Charge for 33 hours; (3) then charge at 0.06C 10 Charge for 12 hours; (4) then charge at 0.1C 10 Discharge for 7 hours; (5) then use 0.1C 10 Charge for 10 hours; (6) then charge at 0.05C 10 Charge for 9 hours; then, (7) stand still for 0.5 hours; (8) charge at 0.1C 10 Discharge for 8 hours; (9) then use 0.1C 10 Charge for 9 hours; (10) then charge at 0.06C 10 Charge for 5 hours.

[0015] During the charging process, pay attention to controlling the battery...

Embodiment 2

[0017] specifically is:

[0018] (1) at 0.04C 10 Charge for 5 hours; (2) then charge at 0.15C 10 Charge for 32 hours; (3) then charge at 0.07C 10 Charge for 11 hours; (4) then charge at 0.11C 10 Discharge for 8 hours; (5) then at 0.11C 10 Charge for 11 hours; (6) then charge at 0.07C 10 Charge for 10 hours; then, (7) stand still for 0.7 hours; (8) charge at 0.11C 10 Discharge for 9 hours; (9) and then at 0.11C 10 Charge for 8 hours; (10) then charge at 0.07C 10 Charge for 5 hours.

[0019] All the other implementations are as in Example 1.

Embodiment 3

[0021] specifically is:

[0022] (1) at 0.05C 10 Charge for 5 hours; (2) then charge at 0.15C 10 Charge for 31 hours; (3) then charge at 0.08C 10 Charge for 11 hours; (4) then charge at 0.12C 10 Discharge for 8 hours; (5) then at 0.12C 10 Charge for 10 hours; (6) then charge at 0.08C 10 Charge for 10 hours; then, (7) stand still for 0.6 hours; (8) recharge at 0.12C 10 Discharge for 10 hours; (9) then at 0.12C 10 Charge for 10 hours; (10) then charge at 0.08C 10 Charge for 5 hours.

[0023] All the other implementations are as in Example 1.

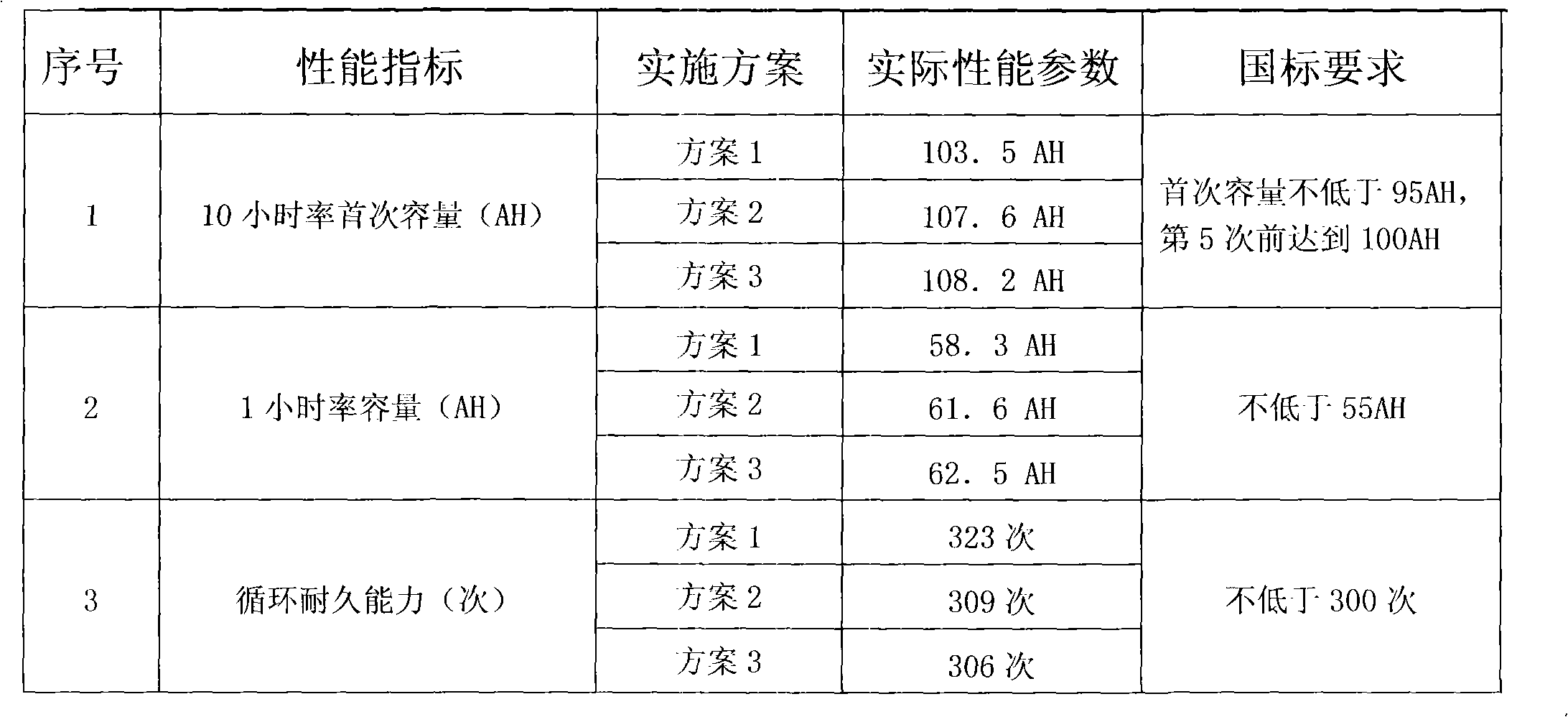

[0024] The performance indicators of the formed battery are as follows (take 12V100AH as an example):

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com