Device for multi-screw volume type continuous metering and material mixing

A metering device and mixing device technology, applied in the field of chemical machinery, can solve the problems affecting the continuity of industrial production and work efficiency, the inability to adjust the proportion of polyester materials in real time, and the inability to realize continuous supply, etc., to achieve accurate mixing and high precision , The effect of reasonable device structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

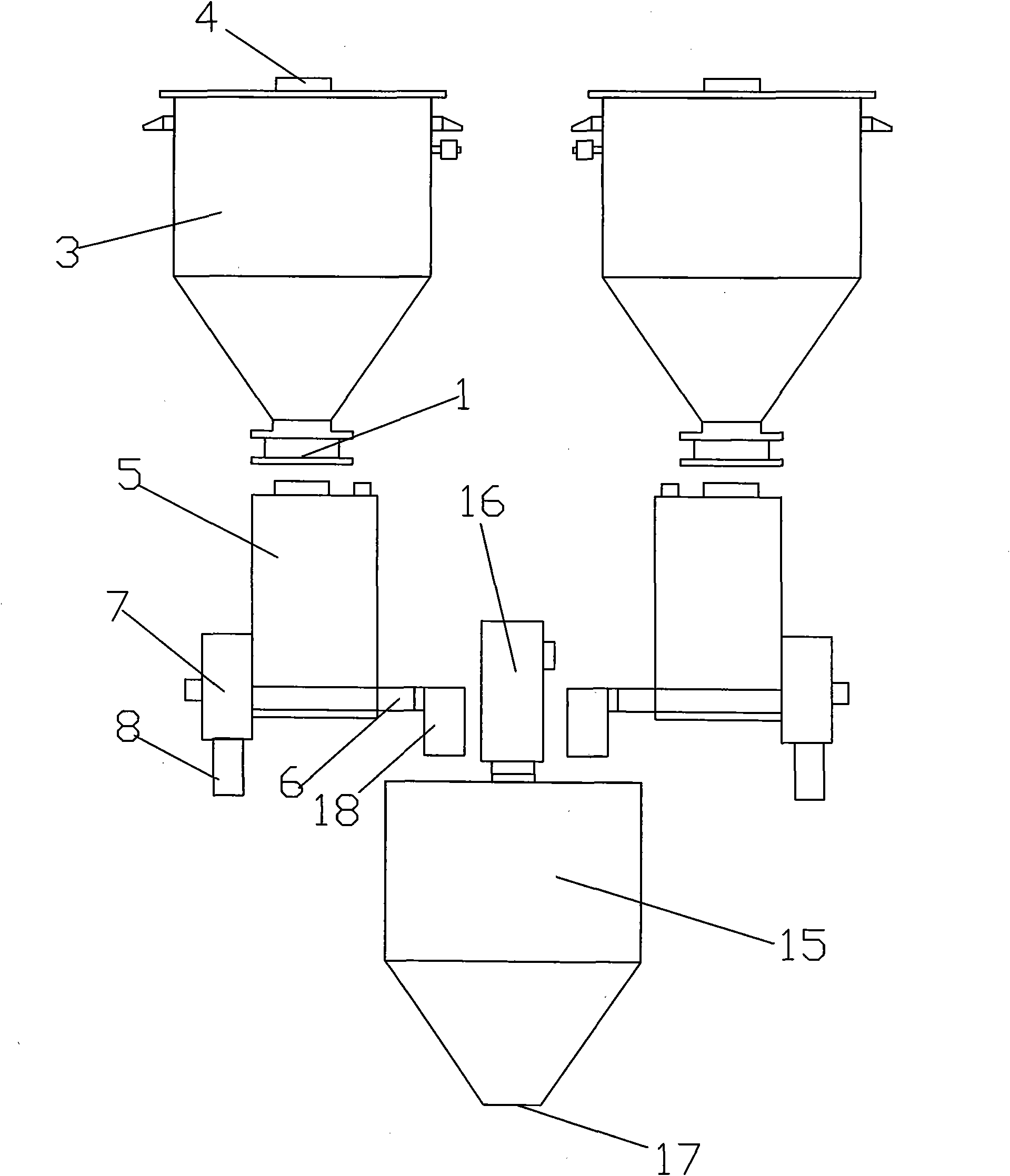

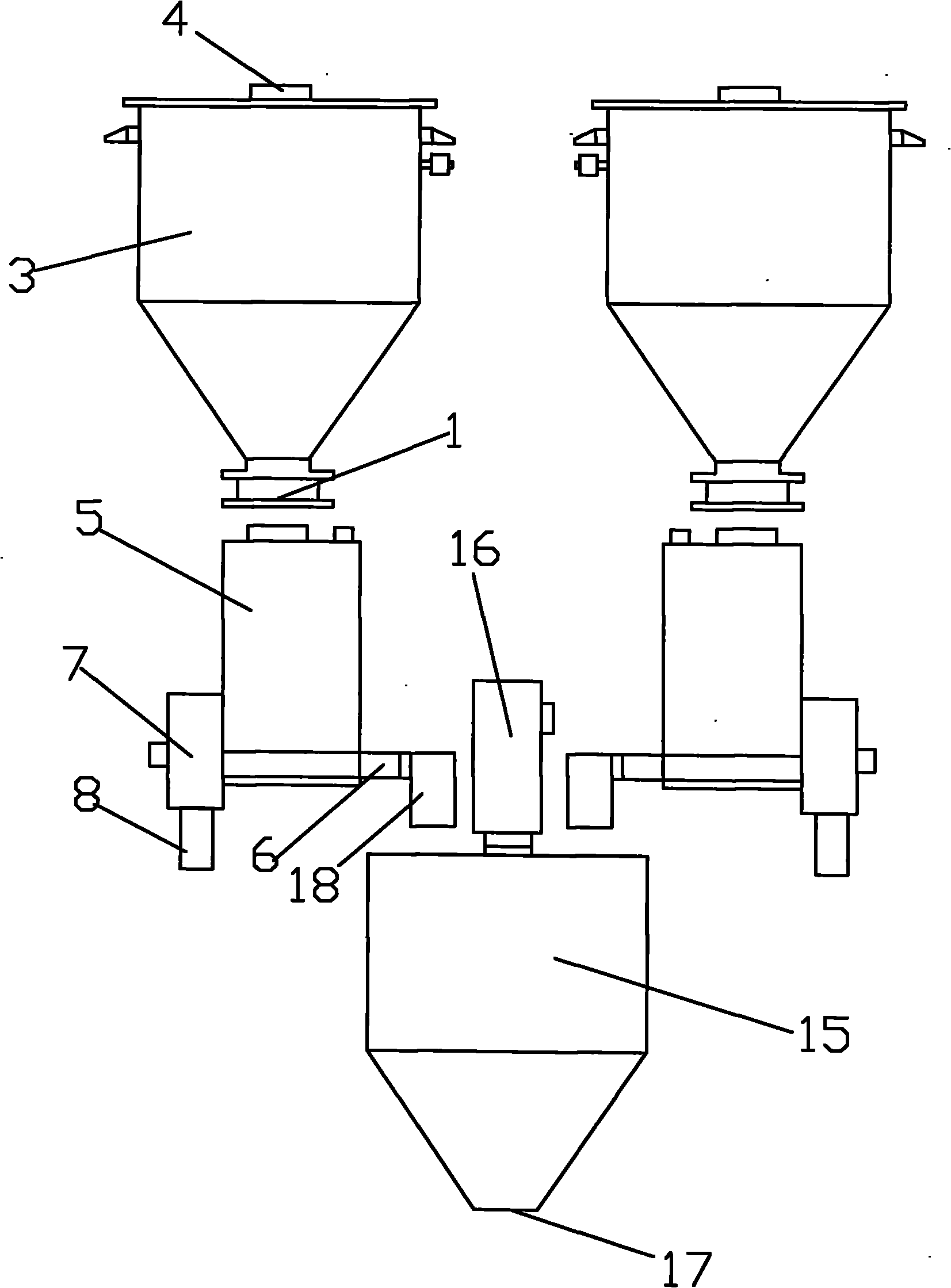

[0014] Such as figure 1 As shown, this embodiment describes a multi-screw volumetric continuous metering and mixing device, which consists of two sets of metering devices and a mixing device.

[0015] The metering device on the left is composed of a feeding bin 3, a feeding tank 5, a screw 6, a screw motor 7, and a screw frequency converter 8. The feeding bin 3 is provided with an inlet 4, an outlet 1, and an inlet 4 It is used to put the recycled polyester material into the feeding bin 3, the outlet 1 corresponds to the lower feeding tank 5, the lower part of the feeding tank 5 is provided with a screw 6, the screw 6 is connected with the screw motor 7, and the screw motor 7 is connected with the screw motor 7. The screw inverter 8 is connected, and the screw 6 is provided with a feeding end 18, which is opposite to the mixing tank 15. The structures of the two sets of metering devices are exactly the same.

[0016] The lower end of the mixing tank 15 is provided with a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com