Torque sensor combined with reducer

A technology of torque sensor and reducer, which is applied in the direction of instruments, torque measurement, transmission parts, etc., can solve the problems of affecting the space size of the transmission chain, affecting the transmission efficiency, and the error of the estimated value, so as to achieve ideal matching and improve the test accuracy , the effect of reducing additional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

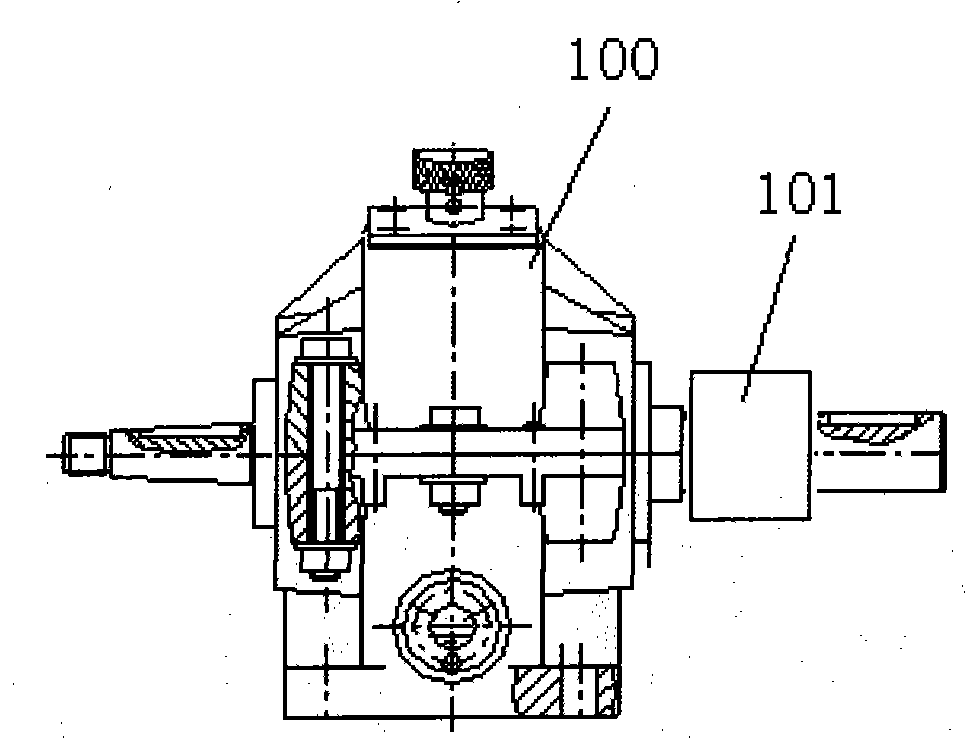

[0037] Such as figure 1 As shown, the torque sensor combined with the speed reducer of the present invention combines the speed reducer 100 and the torque sensor 101 without changing the original structure of the speed reducer, but only increases the length of the output shaft of the speed reducer for A torque sensor 101 is installed. Utilize the torque sensor 101 to directly measure the working torque. Since this test method uses the torque sensor to directly test the load, it will not be affected by other parameters, thereby greatly improving the test accuracy, and because the sensor is directly installed on the output shaft of the reducer, it does not affect the transmission efficiency, making effective Energy can be fully utilized.

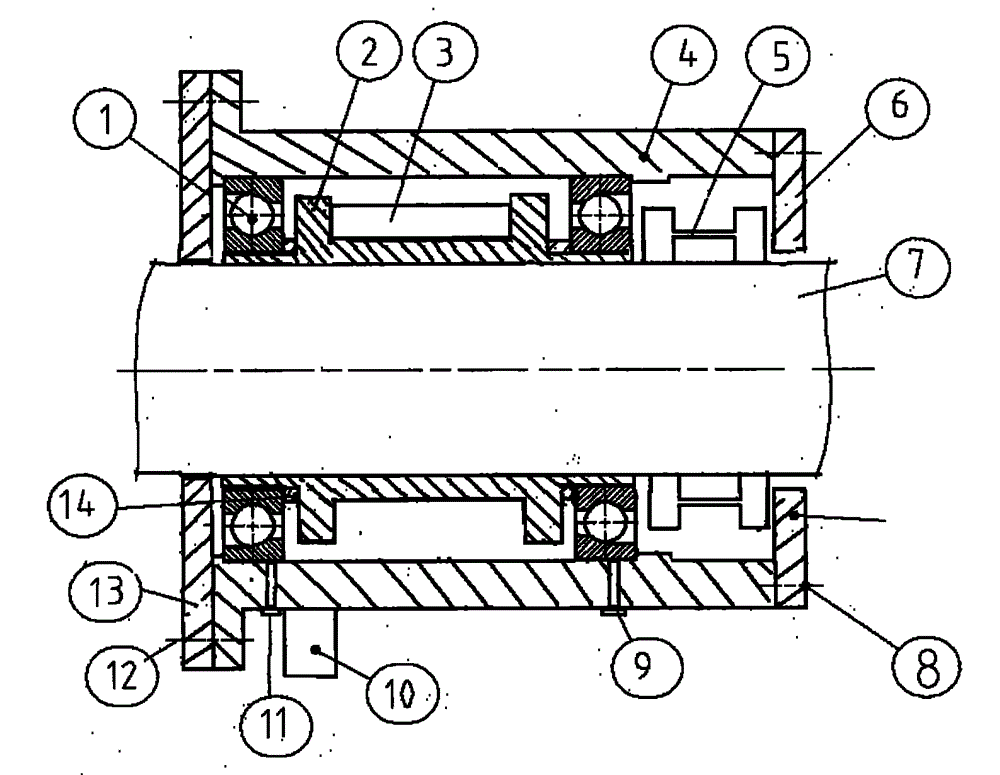

[0038] Such as figure 2 As shown, the torque sensor combined with the speed reducer is equipped with a special t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com