Heat deformation detection instrument

A detector and thermal deformation technology, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of relatively large fluctuation of measurement data, affecting the accuracy of measurement data, affecting the accuracy of test data, etc., to ensure accuracy, low cost, accurate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

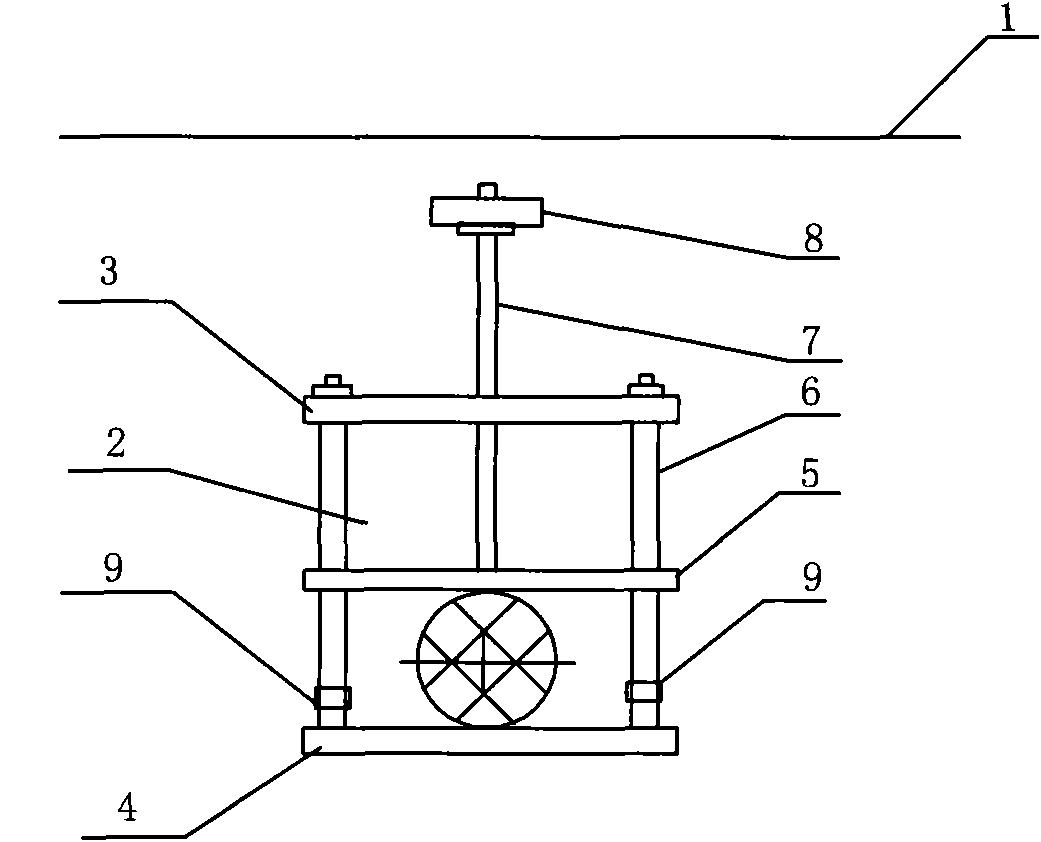

[0016] Such as figure 1 As shown, a thermal deformation detector includes an oven (1), and a sample rack (2) is arranged inside the oven (1). The sample rack includes an upper plate (3), a lower plate (4) and a horizontally arranged upper plate. The load pressing plate (5) between the plate (3) and the lower plate (4), the four corners of the sample holder (2) are provided with guide posts 6 for fixing the upper plate (3) and the lower plate (4), and the guide posts (6 ) vertically through the load platen (5), the load platen (5) can move up and down along the guide post (6), the load platen (5) is vertically provided with a load bar (7) in the center of the upper surface, the load bar (7) passes through The upper plate (3) is connected to the load-bearing plate (8) provided outside the sample holder, and the displacement measuring device (9) is set on the guide post (6) between the load platen (5) and the lower plate (4), namely the cursor .

[0017] experiment procedure: ...

Embodiment 2

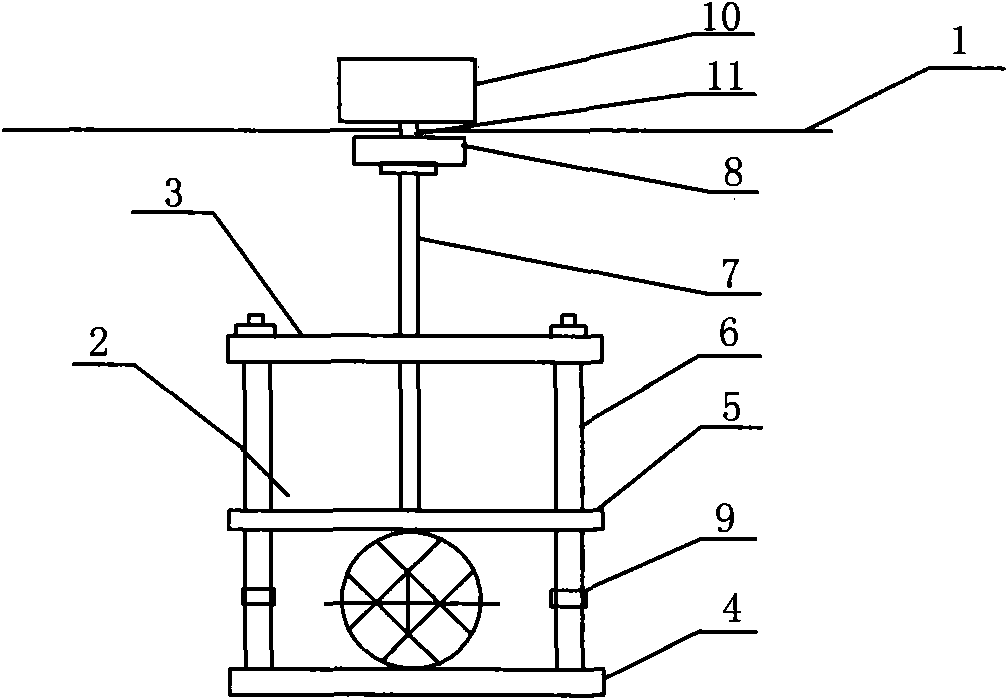

[0031] Such as figure 2 As shown, a thermal deformation detector includes an oven (1), and a sample rack (2) is arranged inside the oven (1). The sample rack includes an upper plate (3), a lower plate (4) and a horizontally arranged upper plate. The load pressing plate (5) between the plate (3) and the lower plate (4), the four corners of the sample holder (2) are provided with guide posts (6) for fixedly connecting the upper plate (3) and the lower plate (4), the guide The column (6) passes through the load pressing plate (5) vertically, and the load pressing plate (5) can move up and down along the guide column (6). 7) Pass through the upper plate (3) and connect with the load-bearing plate (8) provided outside the sample holder, and a displacement measuring device (9) is provided on the guide column (6) between the load platen (5) and the lower plate (4). ) is the displacement sensor, and the oven (1) is provided with a displacement sensor display interface (10) used in c...

Embodiment 3

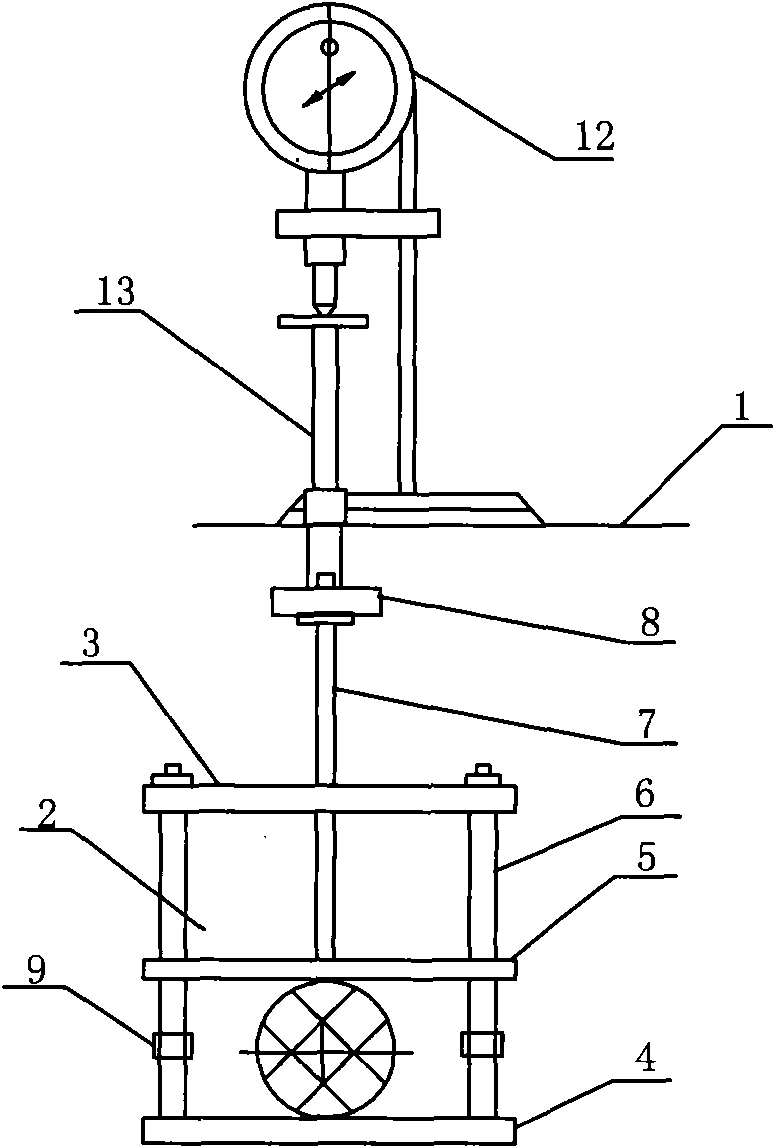

[0047] Such as image 3 As shown, a thermal deformation detector includes an oven (1), and a sample rack (2) is arranged inside the oven (1). The sample rack includes an upper plate (3), a lower plate (4) and a horizontally arranged upper plate. The load pressing plate (5) between the plate (3) and the lower plate (4), and the guide column (6) for fixedly connecting the upper plate (3) and the lower plate (4) are arranged around the sample holder (2), the guide The column (6) passes through the load pressing plate (5) vertically, and the load pressing plate (5) can move up and down along the guide column (6). 7) Pass through the upper plate (3) and connect with the load-bearing plate (8) provided outside the sample holder, and a displacement measuring device (9) is provided on the guide column (6) between the load platen (5) and the lower plate (4). ), the oven (1) is provided with a dial indicator (12), and the dial indicator (12) is connected with the center of the load-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com