Press-processing method, and press-processing apparatus

一种冲压成形、压边的技术,应用在冲压成形及冲压成形装置领域,能够解决难以应用等问题,达到提高稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

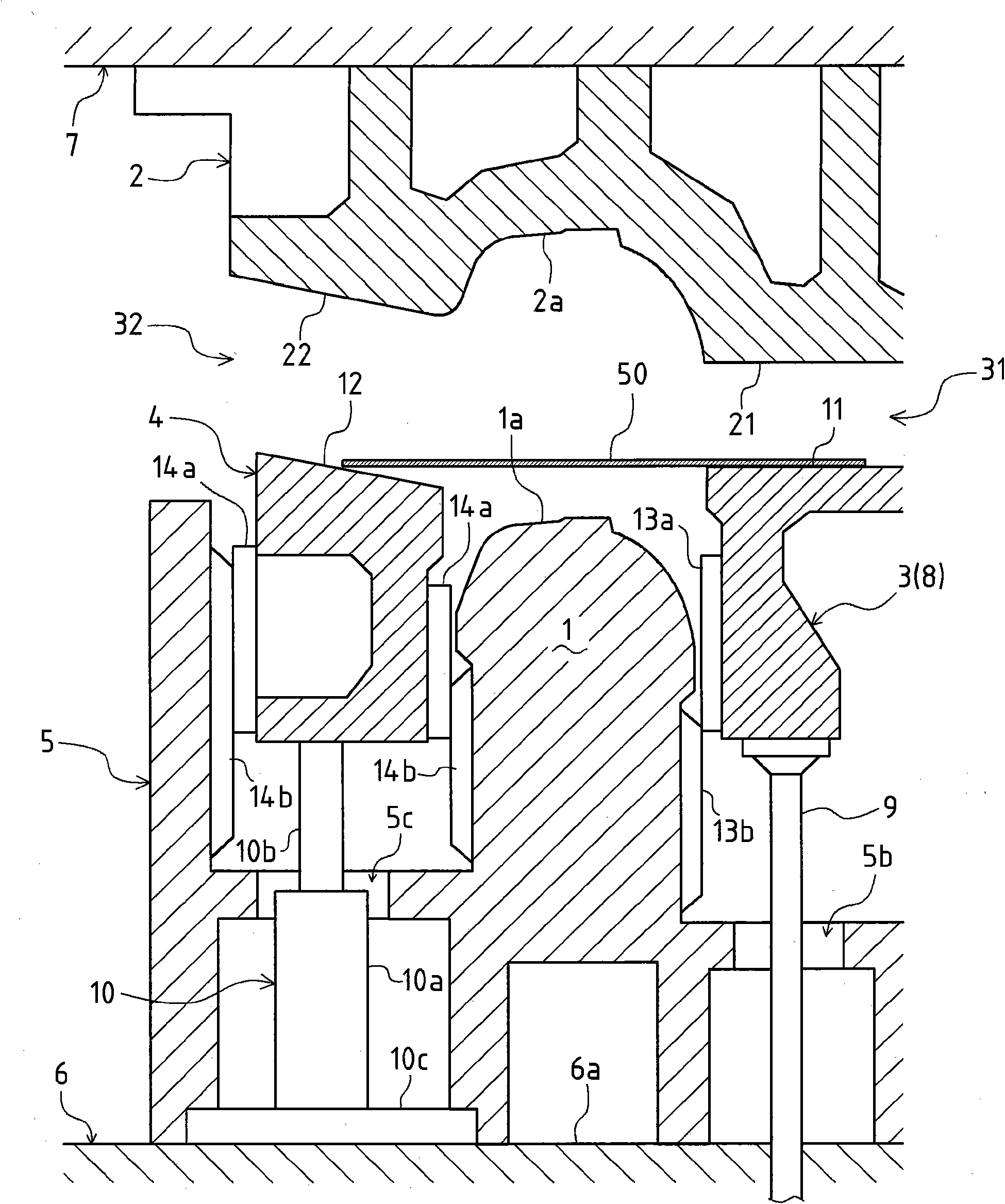

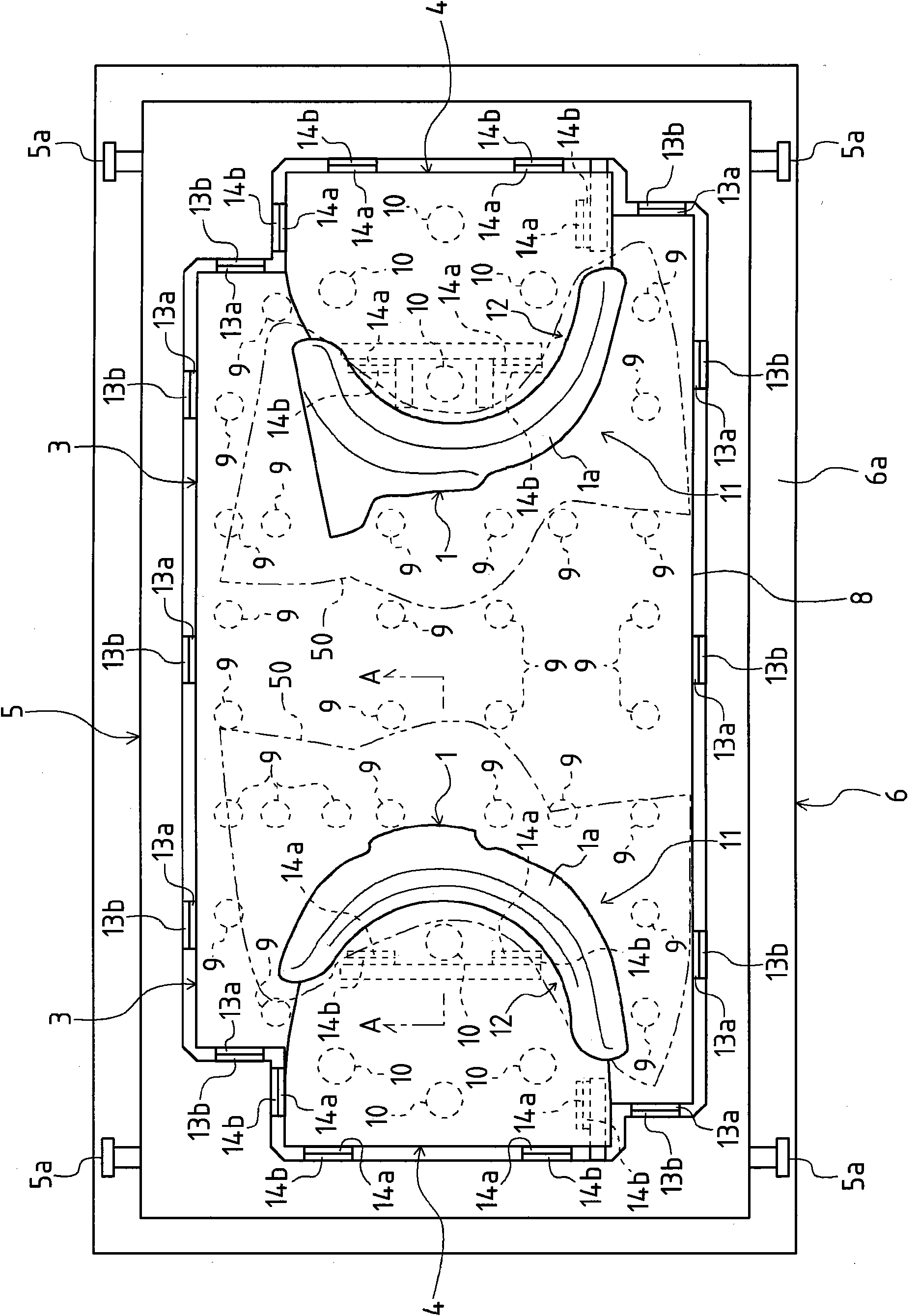

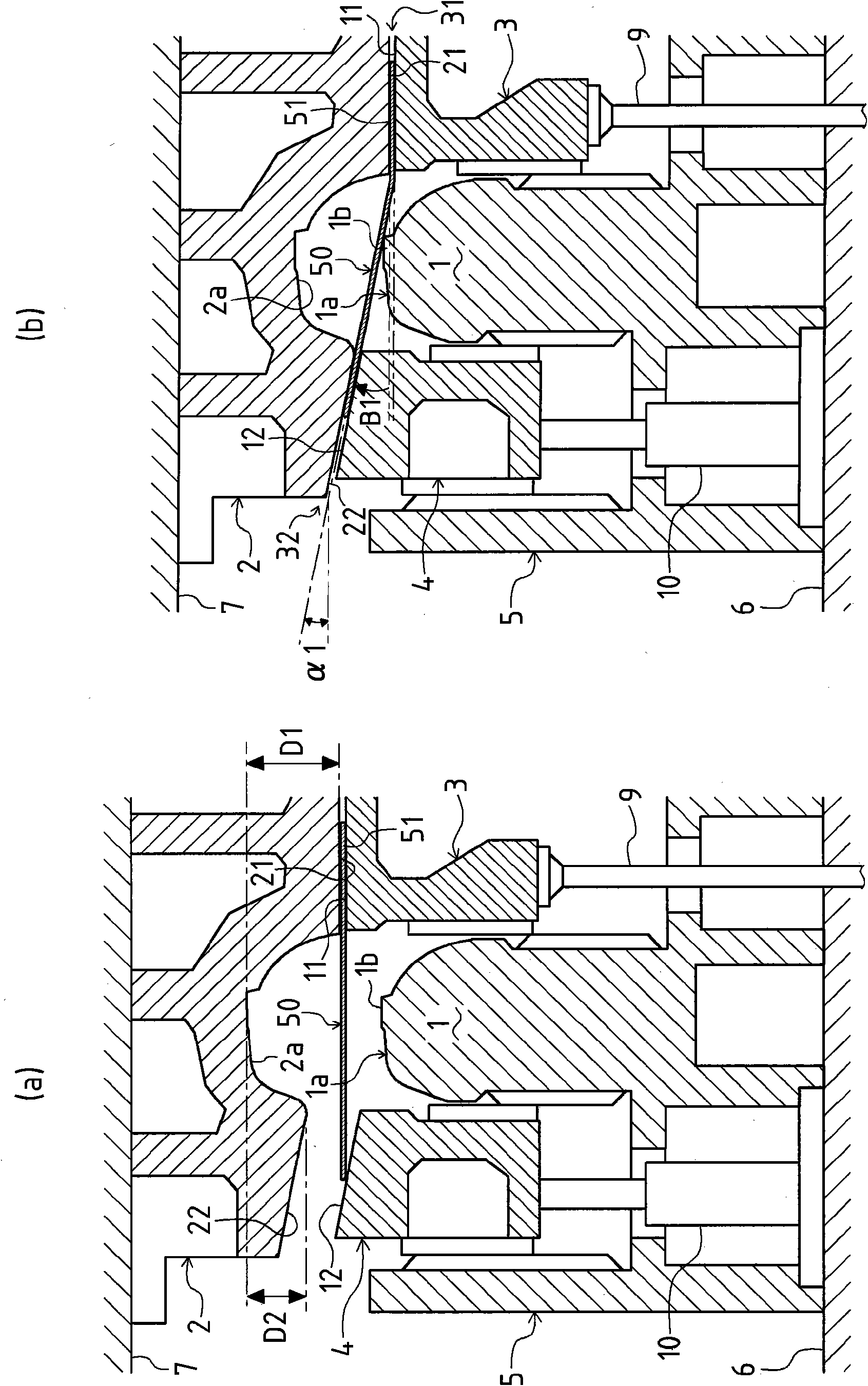

[0032] In the present invention, in press forming in which a plate-shaped blank (blank) is drawn into a predetermined shape having a relatively complicated curved surface shape, when performing blank-holding of the blank before drawing, such as a punch, etc. act on the blank, based on Due to the difference in the forming amount (drawing depth) of the blank due to the above-mentioned asymmetrical predetermined shape, the blank is subjected to two-stage blank-holding at different timings for each part. Then, deformation is applied to the blank in the state where the previous hemming is performed when the subsequent hemming is performed.

[0033]Specifically, when the latter blanking is performed, the billet that is flat at the time when the previous blanking is performed starts from the part on the side where the latter blanking is performed, and for the blank that was clamped by the previous blanking, Partially deformed to one side in the drawing direction. Here, the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com