Method for controlling a stationary gas motor

A gas engine, stationary technology, applied in the direction of combustion engine, internal combustion piston engine, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

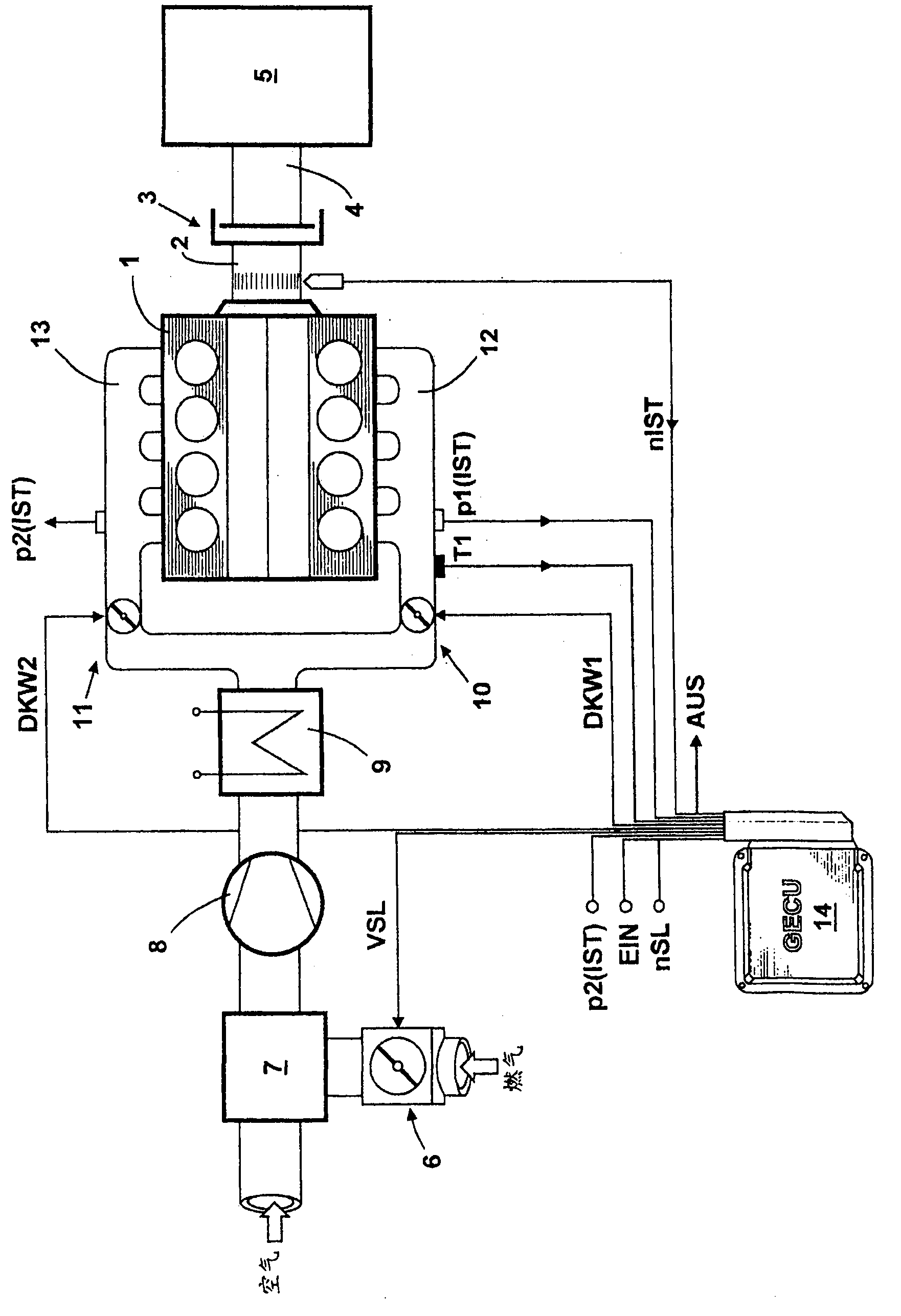

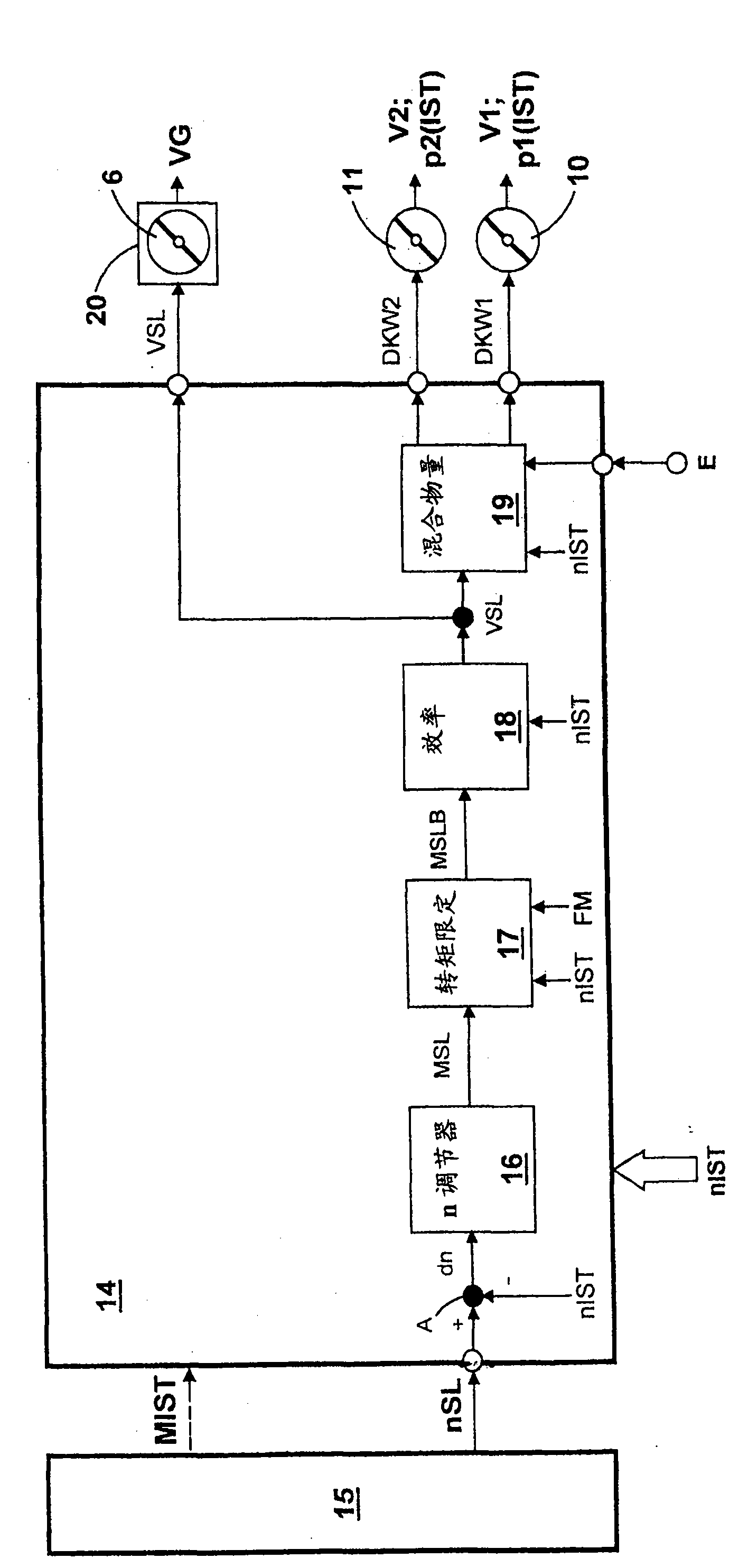

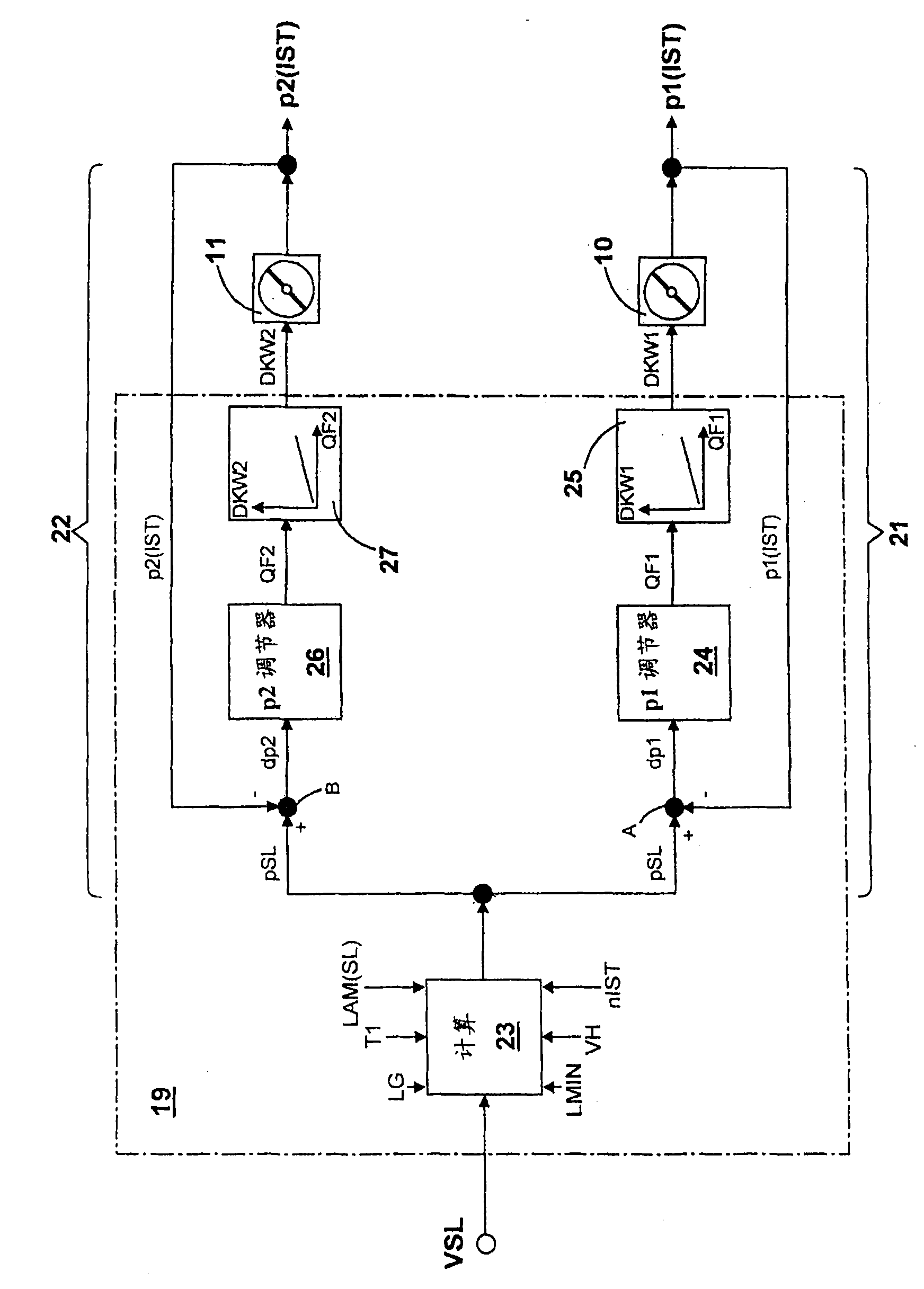

[0015] figure 1 A general view of a stationary gas engine 1 arranged in a V shape is shown. Gas engine 1 drives generator 5 via shaft 2 , clutch 3 and shaft 4 . Electrical energy is generated by the generator 5 and fed into the grid. The gas engine 1 is associated with the following mechanical components: a gas throttle valve 6 for determining the volume flow of the delivered gas (e.g. exhaust gas); a mixer 7 for combining air and gas; as an exhaust gas turbocharger compressor 8 ; cooler 9 ; a first mixture throttle valve 10 on the A side of the gas engine 1 and a second mixture throttle valve 11 on the B side of the gas engine 1 .

[0016] The mode of operation of gas engine 1 is determined by electronic engine controller 14 (GECU). The electronic engine controller 14 contains the usual components of a microcomputer system, such as a microprocessor, I / O modules, buffers and memory modules (EEPROM, RAM). Operating data relating to the operation of the gas engine 1 are impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com