Preheater for heating molten alloy

A liquid alloy and preheater technology, applied in water heaters, fluid heaters, and the shape of heating elements, etc., can solve the problems of shortening the service life of heating wires, increasing the temperature of heating wires, and lengthening material pipelines, etc., so as to save materials and space, reduce the overall size, the effect of compact arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

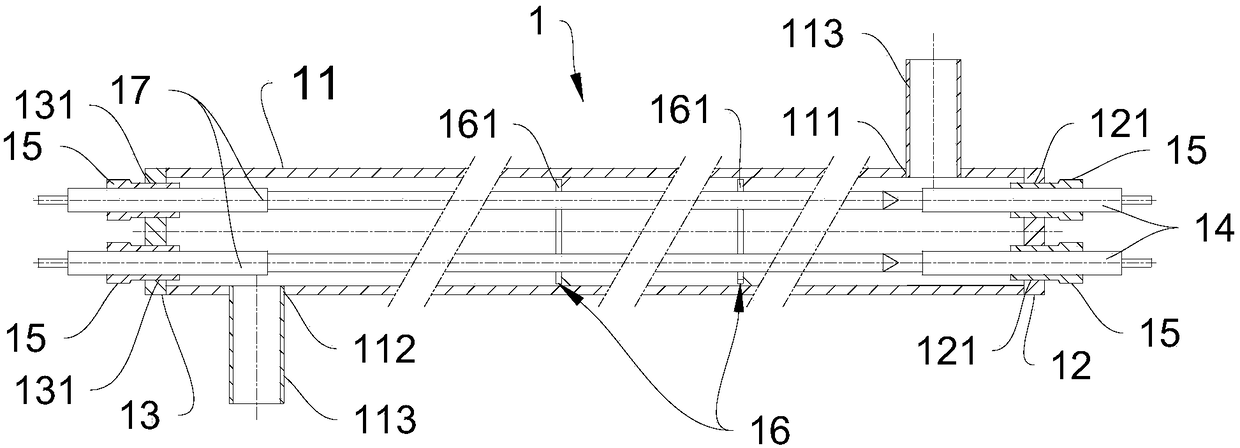

[0035] like figure 1 As shown, the preheater for heating liquid alloy in a preferred embodiment of the present invention includes a preheating assembly 1, and there may be one preheating assembly 1, or there may be multiple preheating assemblies.

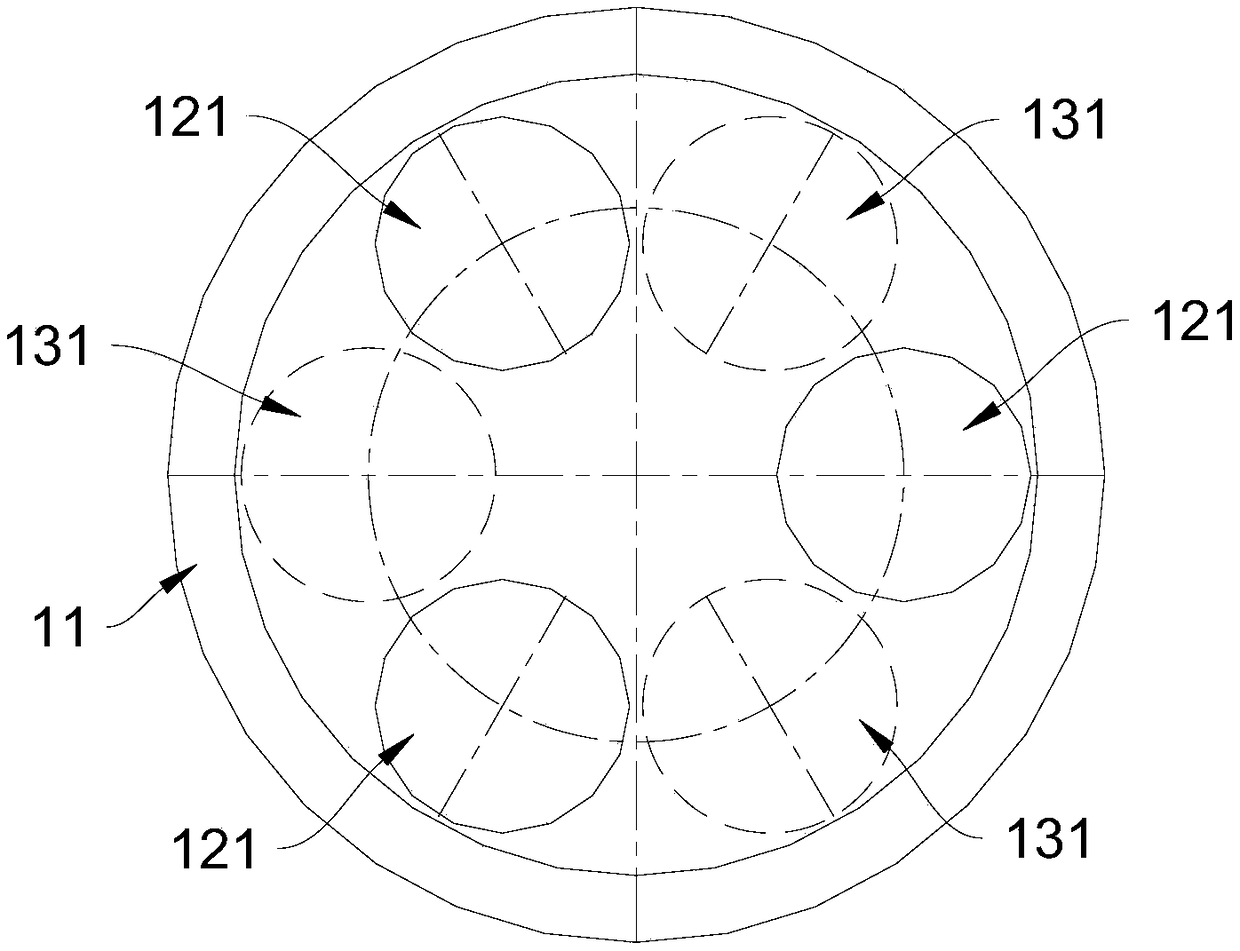

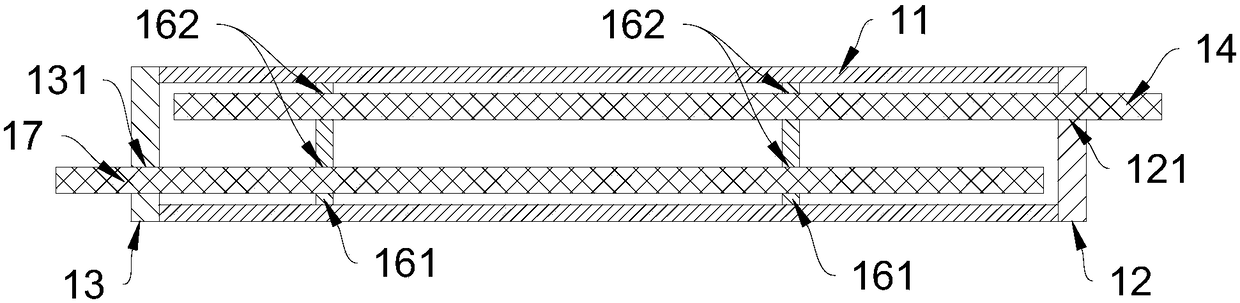

[0036] In some embodiments, the preheating assembly 1 includes a cylinder body 11 , a first end cover 12 , a second end cover 13 , three first heating rods 14 , and three second heating rods 17 .

[0037] The side wall of the cylinder body 11 is provided with a first interface 111 and a second interface 112. The first interface 111 and the second interface 112 are respectively close to the two ends of the cylinder body 11, allowing the liquid alloy to pass through the first i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com