Combined woven screen vibrating screen

A vibrating screen and combined technology, which is applied in the field of mining machinery manufacturing and woven screen vibrating screen manufacturing, can solve the problems of damage to the middle beam and beam of the screen and screen frame, high replacement costs, and insufficient tension, etc., to achieve Synchronization of screen mesh and screen frame vibration, easy fixing and disassembly, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

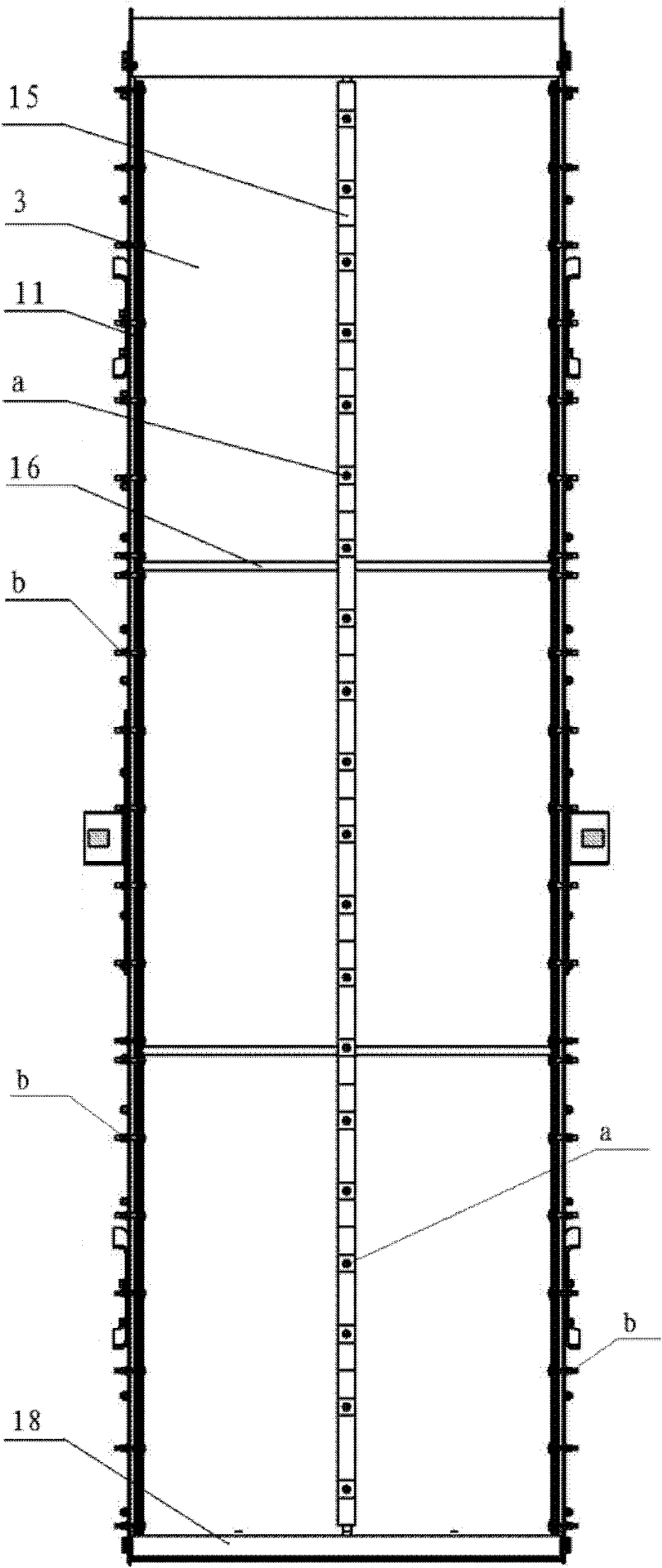

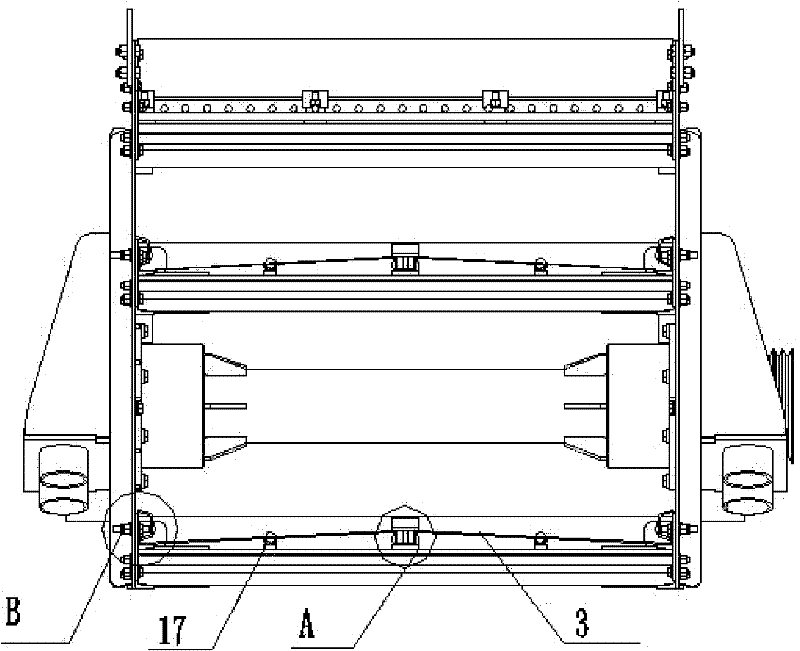

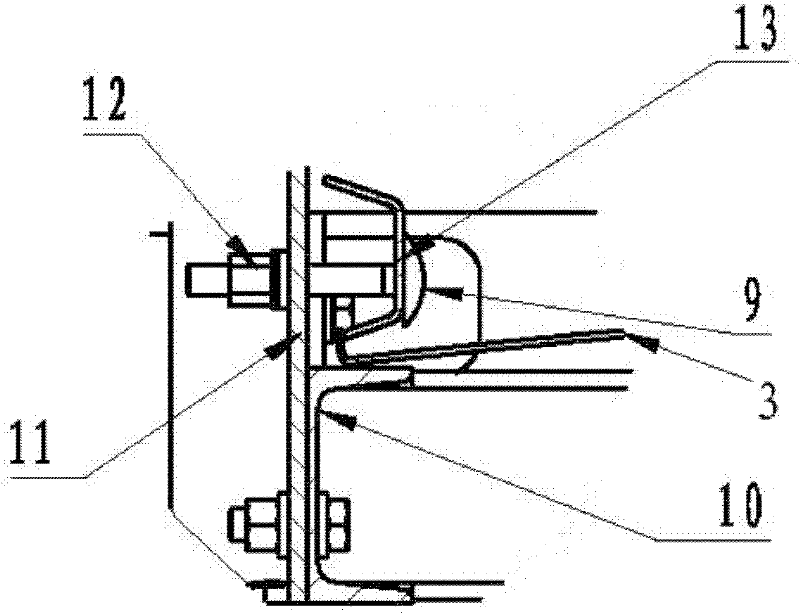

[0033] The woven screen combined vibrating screen in this example includes a vibrating device, a screen box, and a woven screen; the screen box includes a beam, a middle beam, an end plate, and a side plate; There are two beams in the horizontal direction; the section of the woven screen is Z-shaped, and each vibrating screen is composed of two woven screens. The two woven screens are respectively installed on both sides of the middle beam, and the Z-shaped ends of the woven screen are fixed on On the side panels and the center beam, tie the edges upward on the side panels and downward on the center beam.

[0034] The structure of the upward binding on the side panels is the same as image 3 and its description.

[0035] The structure of the downward binding on the middle beam is the same as Figure 4 and its description.

[0036] The two sides of the U-shaped groove used are inclined 60 degrees inward, the side length is 40mm, and the width of the upper opening is about 60...

specific Embodiment 2

[0038] The woven screen combined vibrating screen is composed of six woven screens in this example, and the other structures are the same as those in Embodiment 1.

[0039] Installation steps: After assembling and preparing the screen box, first install the woven screen from the discharge port, spread the screen tightly on the edge of the discharge port of the vibrating screen, tie the edge up close to the side plate, and hook it downward U-shaped groove, the second screen only needs to overlap 20-30mm at the joint of the screen, and the other assembly forms are the same as the first one, and there are three screens on each side of the center beam. Install the tensioning plate and pressure plate separately, pre-tension the tensioning plate appropriately first, then tighten the pressure plate bolts, and finally tighten the tensioning plate bolts.

[0040] During concrete production combination, also can have four, eight, ten structures such as. Its installation method is the s...

specific Embodiment 3

[0041] This example is the same as Embodiment 1 or Embodiment 2, except that there are two rubber strips in the longitudinal direction of the screen box; they are respectively located on both sides of the center beam, in the middle of the center beam and the side plates, and under the woven screen. The rubber strip 17 is fixedly installed on the steel strip, and the steel strip is welded and fixed on the end plate 18, the beam 16 and the discharge port. The rubber strip 17 further increases the horizontal support of the screen, reduces the deformation of the screen, and makes the vibration of the screen and the screen frame more stable. Synchronize.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com