Target seat structure

A target holder and pedestal technology, applied in the field of target holder structure, can solve the problems of discontinuous distribution of columnar target holder, uneven film thickness of plated objects, uneven distribution of atomic concentration of target materials, etc., so as to improve the uniformity, The effect of uniform target atomic concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

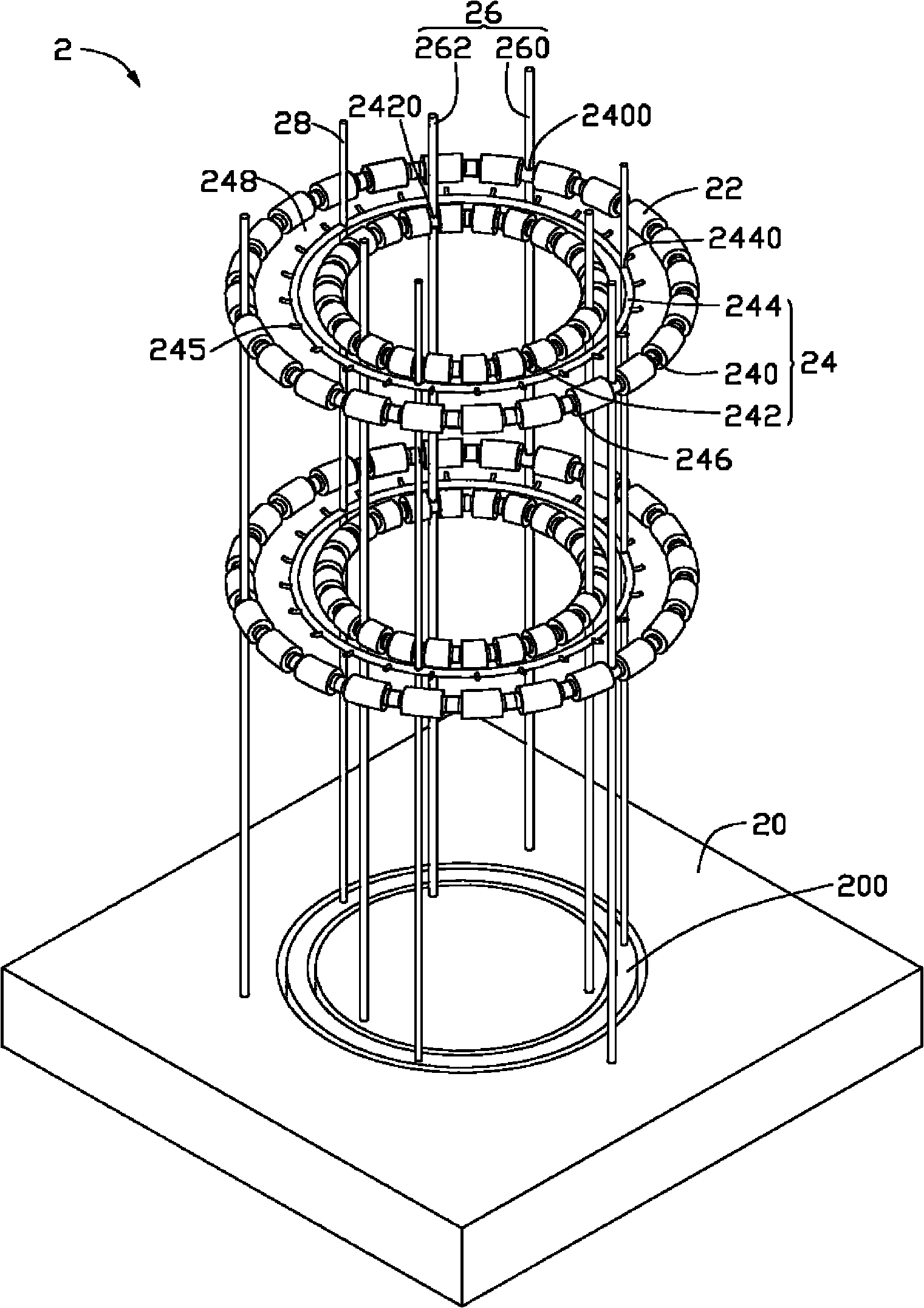

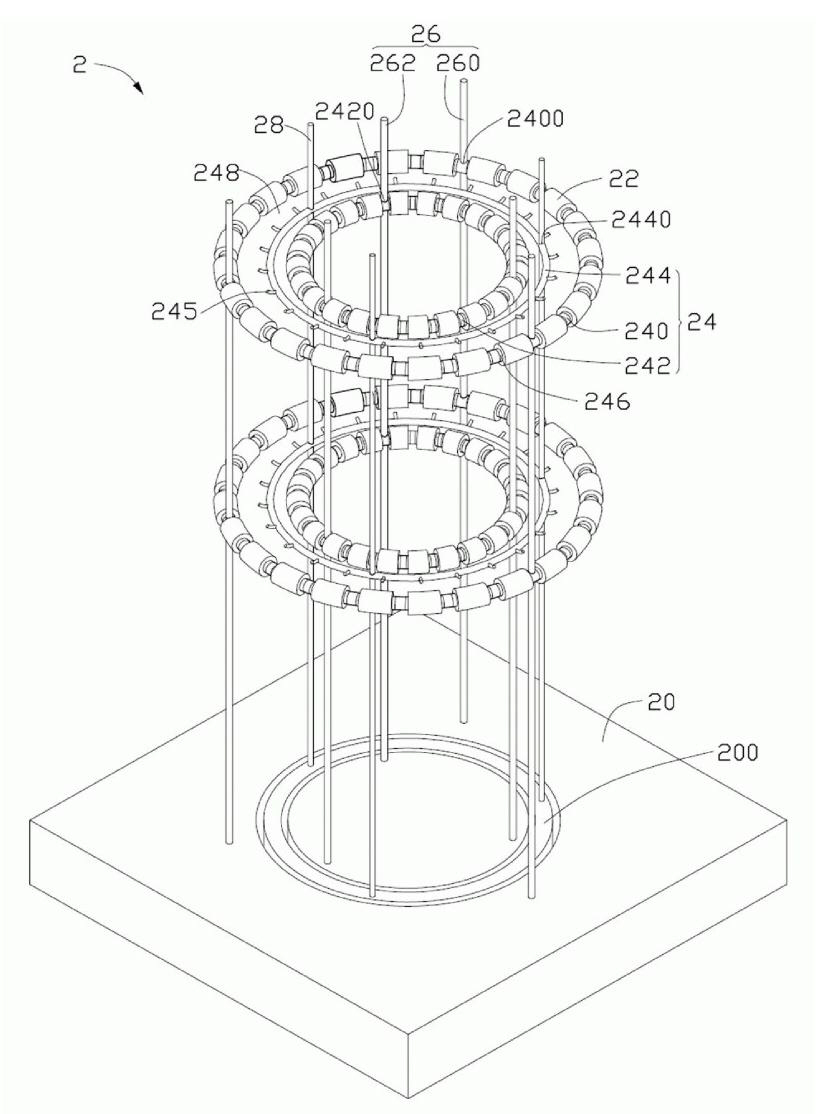

[0008] Such as figure 1 As shown, the target holder structure 2 provided by the embodiment of the present invention includes a base 20 , a target material 22 , a coating layer 24 , a target holder support 26 and a base support 28 .

[0009] The coating layer 24 includes a first target base 240 , a second target base 242 and a base 244 . The first target seat 240 , the base 244 and the second target seat 242 are concentric annular bodies with successively decreasing diameters.

[0010] The target stand support 26 can be a plurality of upright poles fixedly connected to the base 20, which includes a first target stand support 260 for supporting the first target stand 240 and a support for supporting the second target stand 242. The second target holder bracket 262 . A plurality of first connection through holes 2400 are evenly spaced on the first target base 240 , and the first target base bracket 260 passes through the first connection through holes 2400 and is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com