Control apparatus and control method for internal combustion engine fuel injection

A fuel injection and control device technology, applied in the directions of fuel injection control, engine control, electrical control, etc., can solve the problems of fuel injection quantity deviation, inability to maintain injection quantity control accuracy, and inability to fully meet the requirements of fuel injection quantity accuracy. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

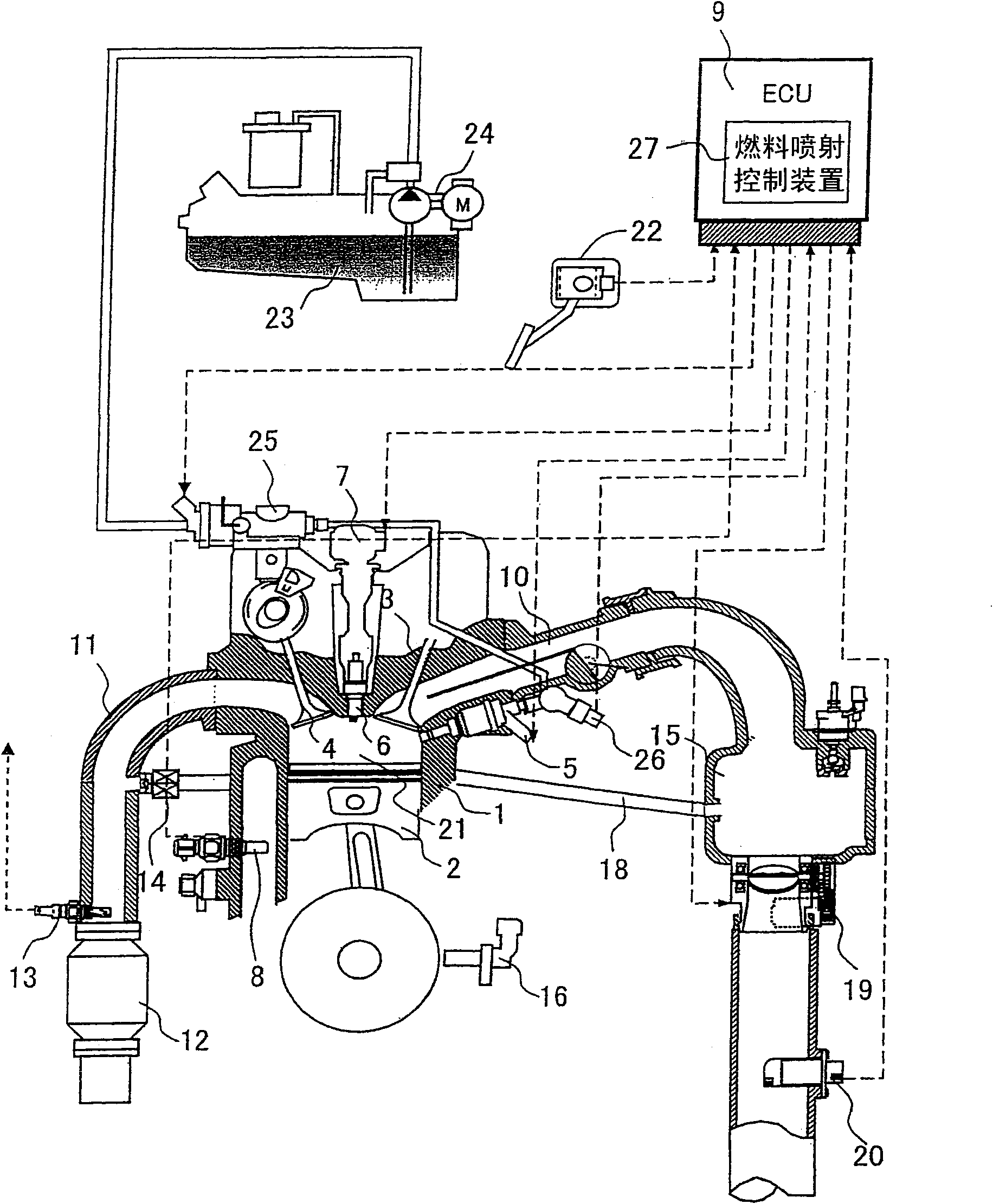

[0054] Below, use Figure 1 to Figure 11 , the configuration and operation of the fuel injection control device according to the embodiment of the present invention will be described.

[0055] First, use figure 1 Next, the configuration of an internal combustion engine system equipped with the fuel injection control device according to the present embodiment will be described. figure 1 It is a configuration diagram of an internal combustion engine system equipped with a fuel injection control device according to a first embodiment of the present invention.

[0056] An internal combustion engine (engine) 1 has a piston 2 , an intake valve 3 and an exhaust valve 4 . Intake air passes through an air flow meter (AFM) 20 , the flow rate of which is adjusted by a throttle valve 19 , and is supplied to a combustion chamber 21 of the engine 1 via an intake pipe 10 and an intake valve 3 from a collector 15 as a branch. Fuel is supplied from a fuel tank 23 to a high-pressure fuel pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com