Pressure accumulation fuel injection controller

一种燃料喷射、燃料喷射阀的技术,应用在燃料喷射控制、燃料喷射装置、电气控制等方向,能够解决发动机燃烧不稳、不稳、发动机性能变化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

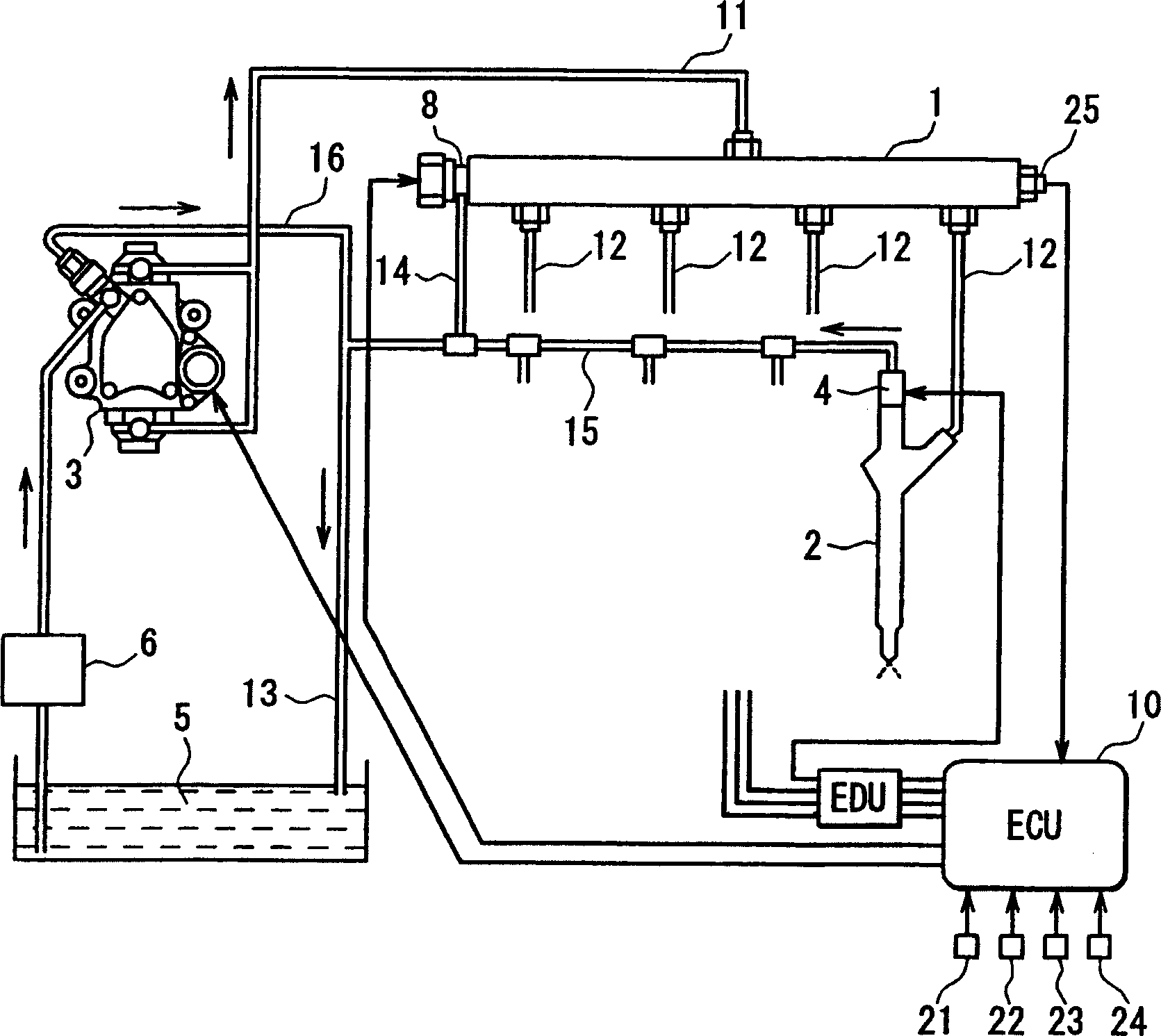

[0014] see figure 1 , which shows an accumulator type fuel injection controller according to an exemplary embodiment of the present invention. This fuel injection controller has a pressure accumulation container 1 (common rail), a plurality (four in the present embodiment) of fuel injection valves (injectors) 2, a fuel supply pump (delivery pump) 3, and an electronic control unit ( ECU) 10. The common rail 1 provides an accumulator for accumulating high-pressure fuel corresponding to the fuel injection pressure. A plurality of injectors 2 are connected to the common rail 1, and inject fuel into each cylinder of a four-cylinder engine, where the four-cylinder engine is, for example, a multi-cylinder diesel engine. The supply pump 3 is driven to rotate by the engine. The ECU 10 functions as a control section for performing electronic control on the plurality of injectors 2 and the charge pump 3 .

[0015] The common rail 1 needs to continuously store high-pressure fuel corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com