Automatic switching dual-path transmission mechanism of punch press

A transmission mechanism and automatic switching technology, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve problems such as small step distance, low load, stamping, high speed, etc., and achieve high practical value, energy saving, The effect of increasing the strike speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

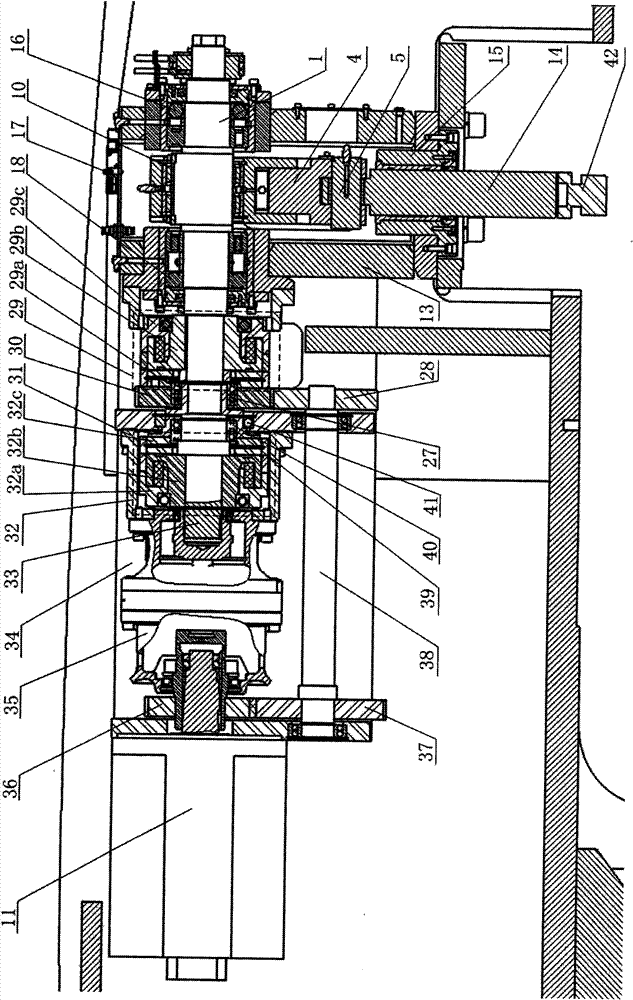

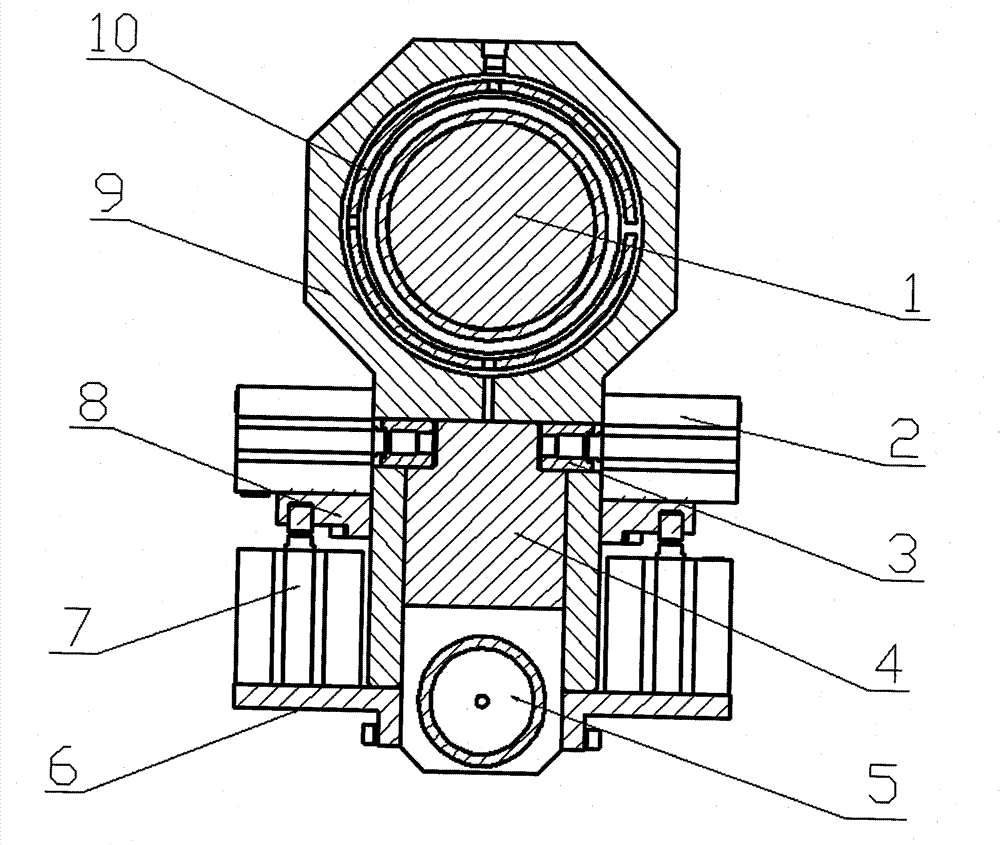

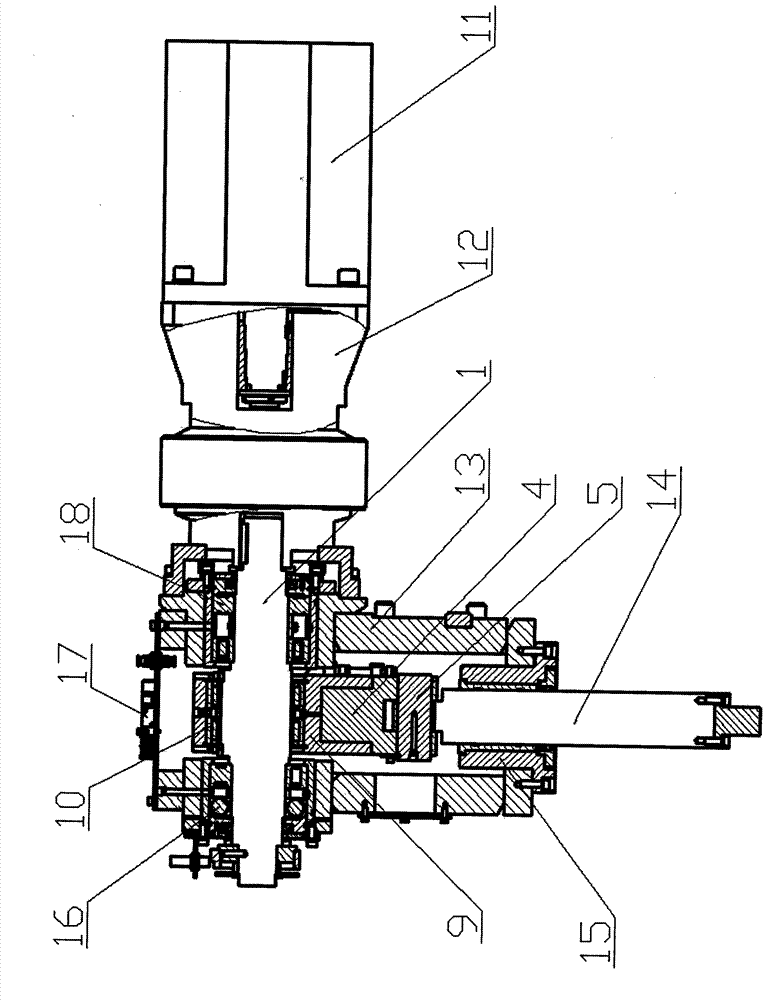

[0027] Embodiment 1: A new dual-channel CNC turret punch press main drive system powered by a CNC servo motor.

[0028] Such as figure 1 As shown, the dual-channel transmission mechanism includes two channels, straight and side, and the straight channel mainly passes through the servo motor 11-reducer 35-straight connecting shaft 33-electromagnetic tooth clutch II32-straight connecting sleeve 39-crankshaft 1-connecting rod-sliding Block 14-the transmission route of the striking head 42 realizes striking action; the bypass path mainly passes through the servo motor 11-gear II36-gear III37-bypass connection shaft 38-gear IV28-gear I30-electromagnetic tooth clutch I29-crankshaft 1-connecting rod -slider 14-strike head 42 realizes strike action.

[0029] In the straight path, the output shaft of the servo motor and the input shaft of the reducer are connected through a shaft sleeve, the output shaft of the reducer and the straight connection shaft 33 are connected through the sp...

Embodiment 2

[0041] Embodiment 2: The main transmission system of a new dual-channel CNC turret punch press powered by a CNC servo motor as the power in the bypass channel using a synchronous belt to transmit power instead of gear meshing.

[0042] The bypass path uses a synchronous belt to transmit power instead of gear meshing to transmit power. The straight path in the main transmission system and the crank-link mechanism with variable connecting rod length are the same as those in Embodiment 1. The bypass path transmission route is "servo motor 11 - synchronous pulley II-synchronous pulley III-bypass connecting shaft 38-synchronous pulley IV-synchronous pulley I-electromagnetic toothed clutch I29-crankshaft 1-connecting rod-slider 14-hitting head 42 ".

[0043] The connection method of each synchronous pulley is the same as that of the gear, that is, the output shaft of the servo motor is connected with the synchronous pulley II through the key, the synchronous pulley II and the synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com