Durable device for controlling powder taking depth and collecting powder

A deep control and durability technology, applied in the direction of sampling devices, etc., can solve the problems of unfavorable health of operators, flying dust, affecting dust collection rate, etc., to achieve the effect of reducing adverse effects, improving work efficiency, and improving credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

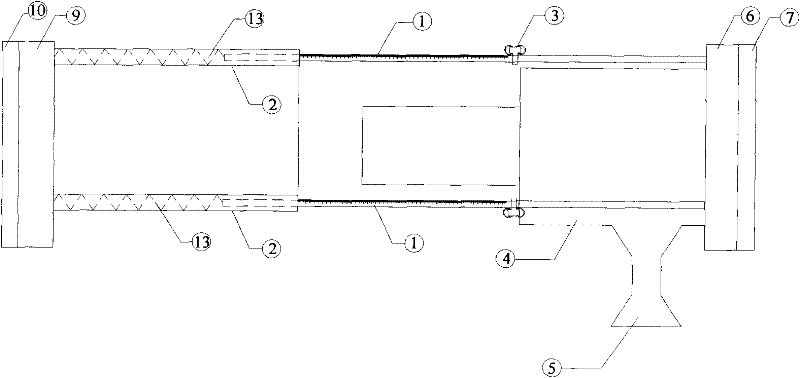

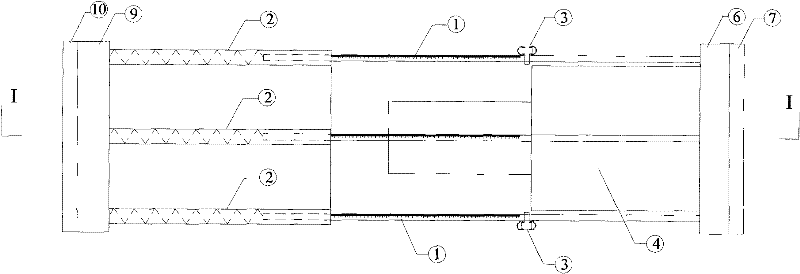

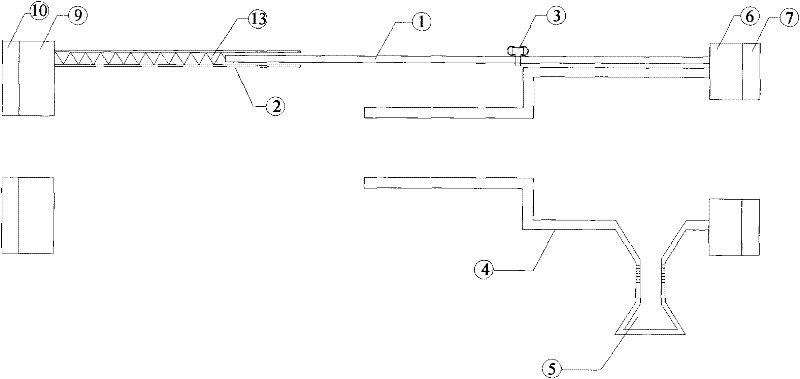

[0013] In the present invention, a scale is engraved on the sliding rod of the control device, which is accurate to millimeter, and a hoop clip is provided, and the fixing and moving of the hoop clip are realized by adjusting the degree of tightness. When the fixed hollow rod on the outside of the slide bar encounters the hoop clamp, the percussion drill bit will stop moving forward, so the depth of each powder extraction can be controlled by setting the position of the hoop clamp. The dust collector mainly includes a powder collection cylinder and a powder collection bottle. The powder collection cylinder seals the dust drilled by the drill bit in a relatively closed space, and collects the dust into a detachable powder collection bottle through the action of its own weight and the shaking of the device. . In order to closely and vertically stick the powder collection tube to the surface of the structure, a spring is provided at the end of the slide bar near the drilling mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com