Manufacturing process of high frequency welded pipe with low inner seam

A high-frequency welded pipe and manufacturing process technology, applied in the field of welded pipe manufacturing, can solve the problems of refrigerator refrigerant leakage, refrigerator not cooling, etc., and achieve the effect of ensuring expansion, improving product quality and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

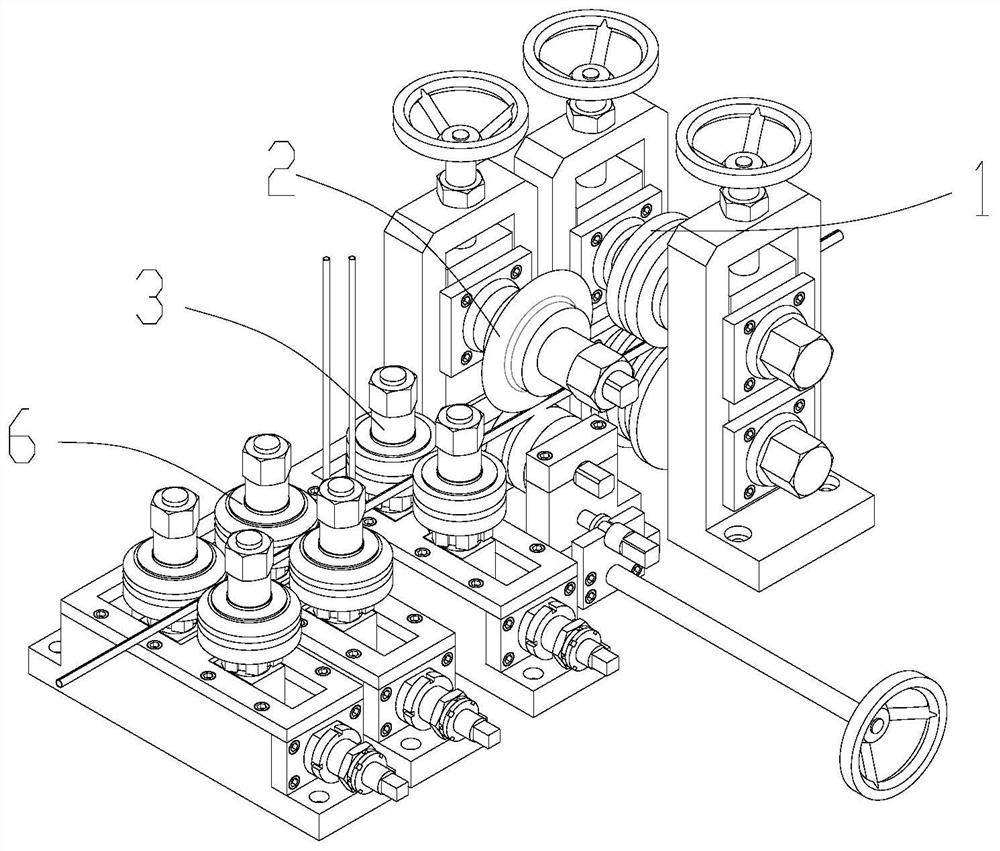

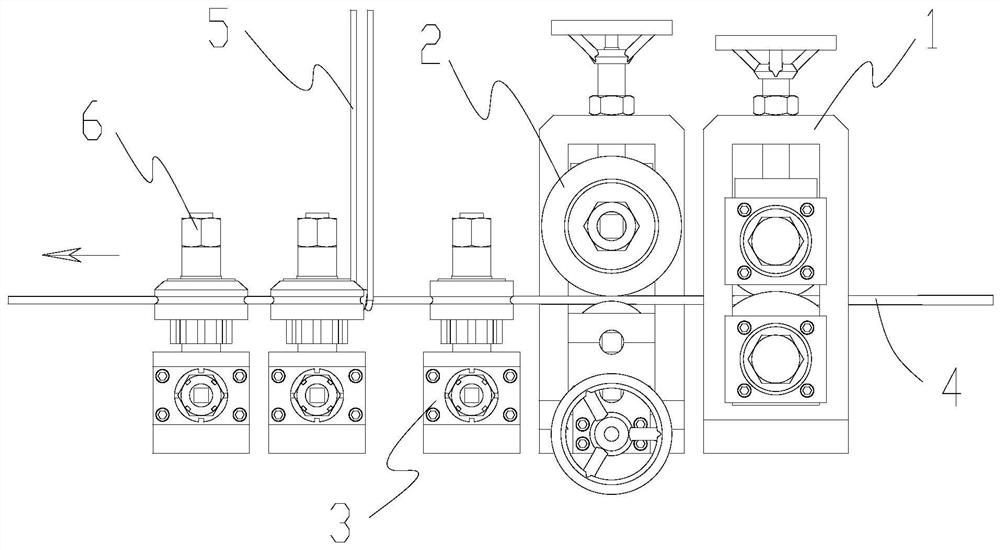

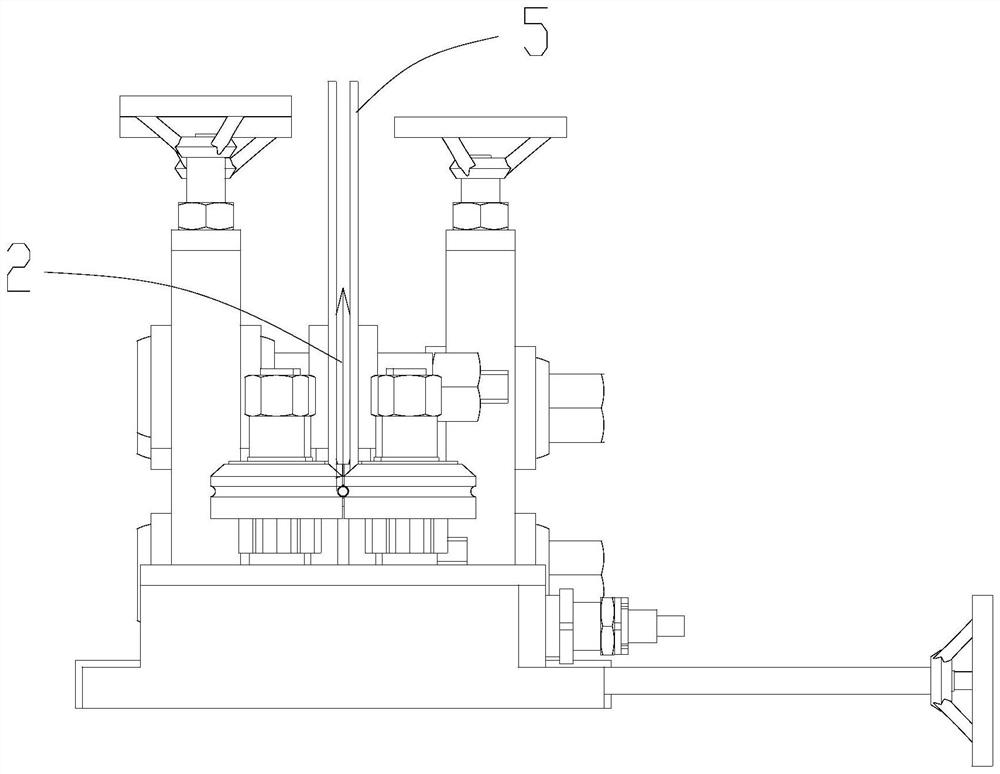

[0036] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0037] see Figure 1 to Figure 6 , the high-frequency welded pipe manufacturing process of a high-precision low-value inner weld in this embodiment has the following steps and means (including hardware design):

[0038] Basic conditions: The strip steel 401 is cut from top to bottom with scissors in the conventional way, and the coiled tube 4 forming die is curled upwards in the conventional way.

[0039] 1. On the assembly line, the edge burrs caused by the strip steel 401 cut into strips are placed opposite to the forming direction of the coiled tube 4, so that the edge burrs 402 of the strip steel strips cut into strips are located in the coiled tube 4 after forming The outside of the coiled tube, that is, the weld line.

[0040] 2. Adjust the passes of the molding die 1 of the high-frequency weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com