Constant temperature electronic oscillation equipment

An electronic oscillation and constant temperature technology, applied in the direction of electrical components, temperature control without auxiliary power supply, impedance network, etc., can solve the problems of inconvenient disassembly, easy deviation from the heating area, and difficulty in adjusting the working temperature of the resonant crystal, so as to improve heat insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below, and examples of the embodiments are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements. The embodiments described below with reference to the figures are exemplary and are intended to explain the present invention, and should not be construed as limiting the present invention.

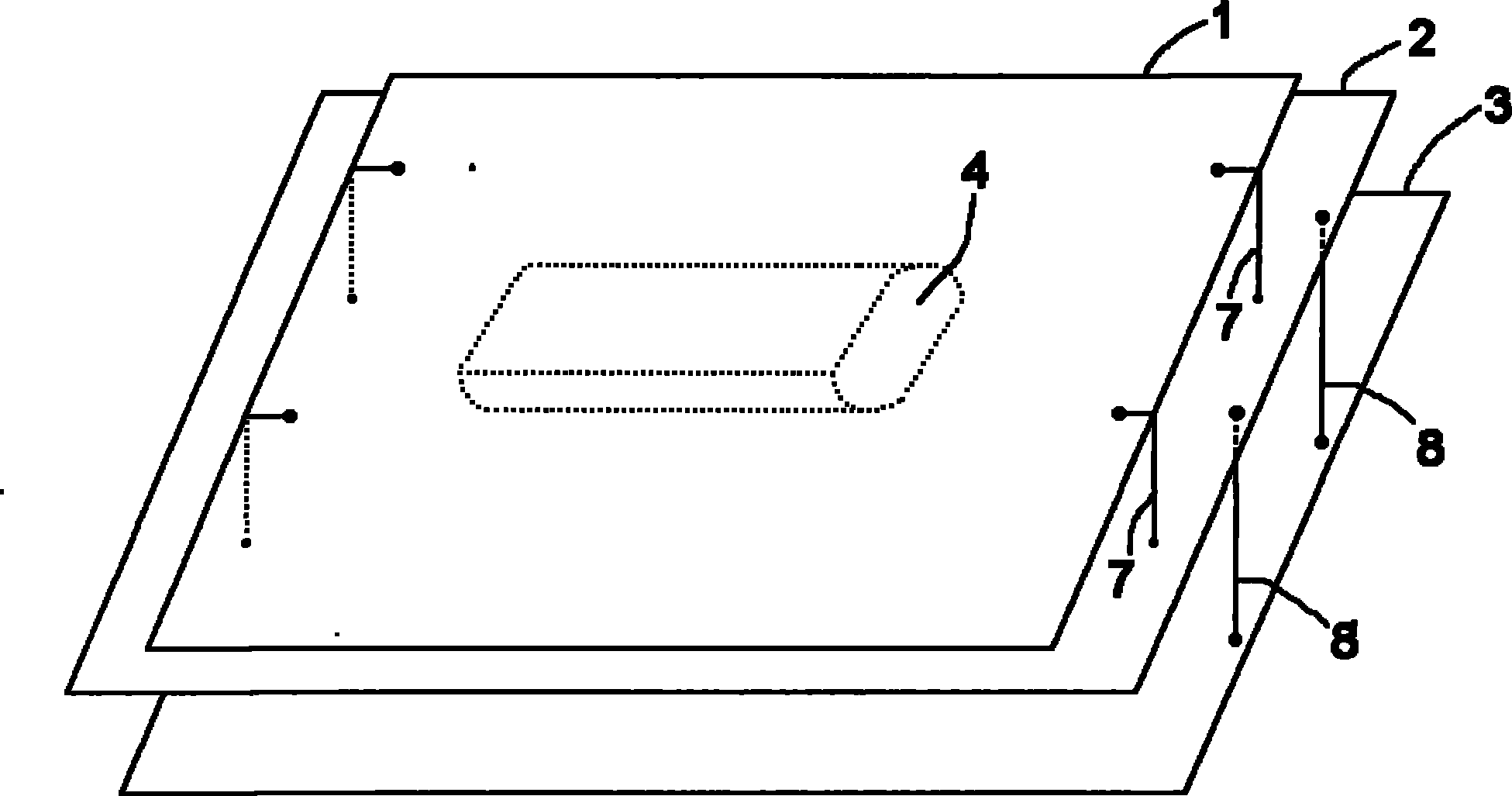

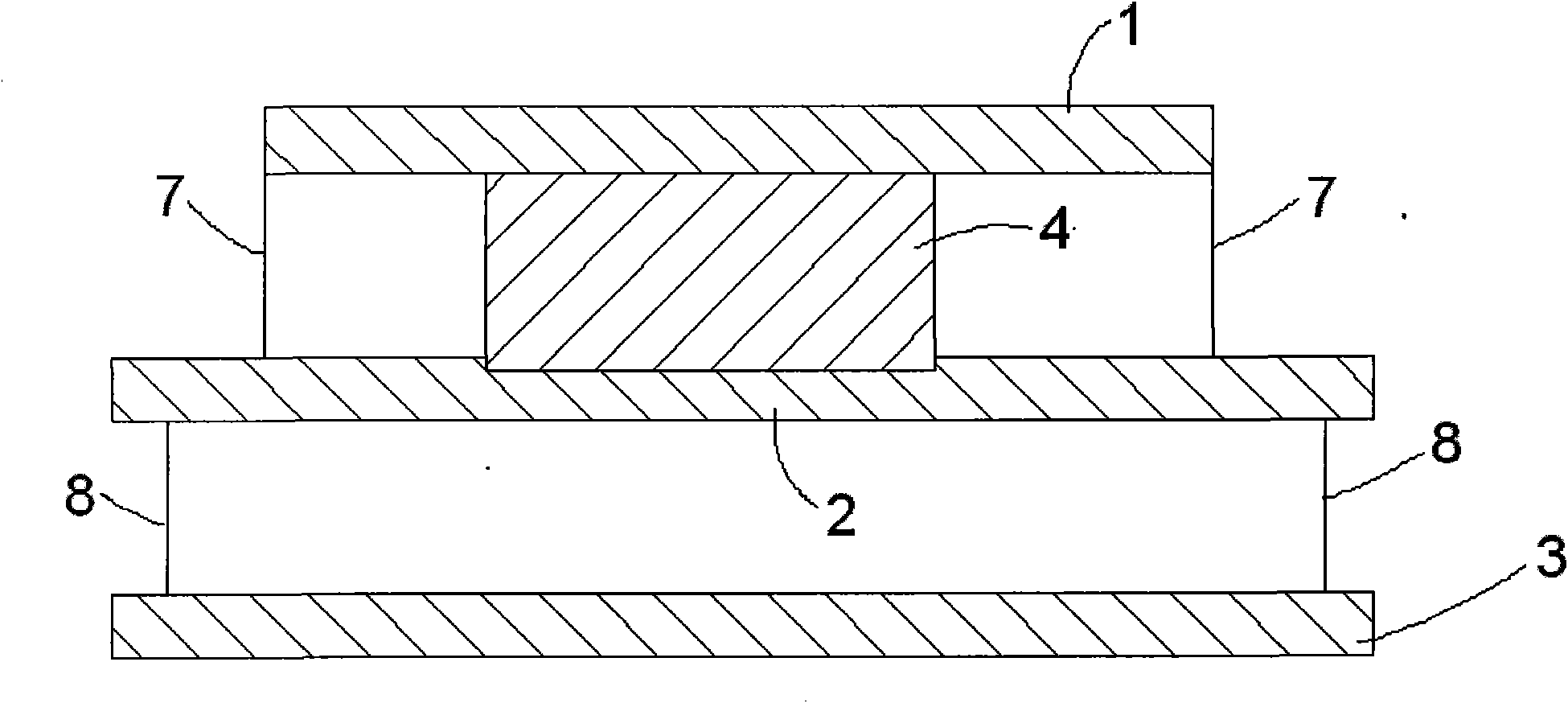

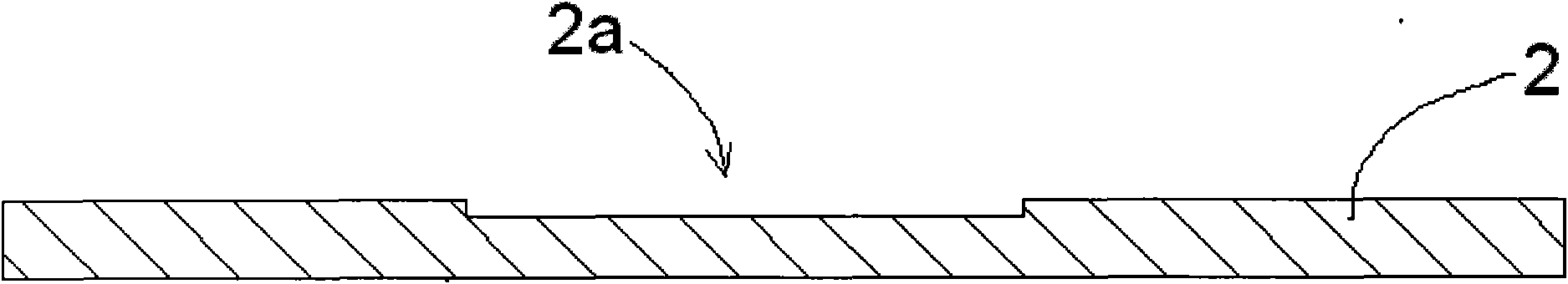

[0018] figure 1 A schematic diagram showing the three-dimensional structure of the constant temperature electronic oscillation device of the present invention; figure 2 A longitudinal sectional view showing the constant temperature electronic oscillation device of the present invention; image 3 A longitudinal sectional view showing the lower printed circuit board of the constant temperature electronic oscillation device of the present invention; and Figure 4 A longitudinal sectional view showing the constant temperature electronic oscillating device of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com