Heat sink

一种散热装置、吸热部的技术,应用在冷却/通风/加热改造、电气元件、电固体器件等方向,能够解决散热模块散热负荷大、散热器散热效率不高、主处理器热量得不到及时散发等问题,达到使用安全可靠的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

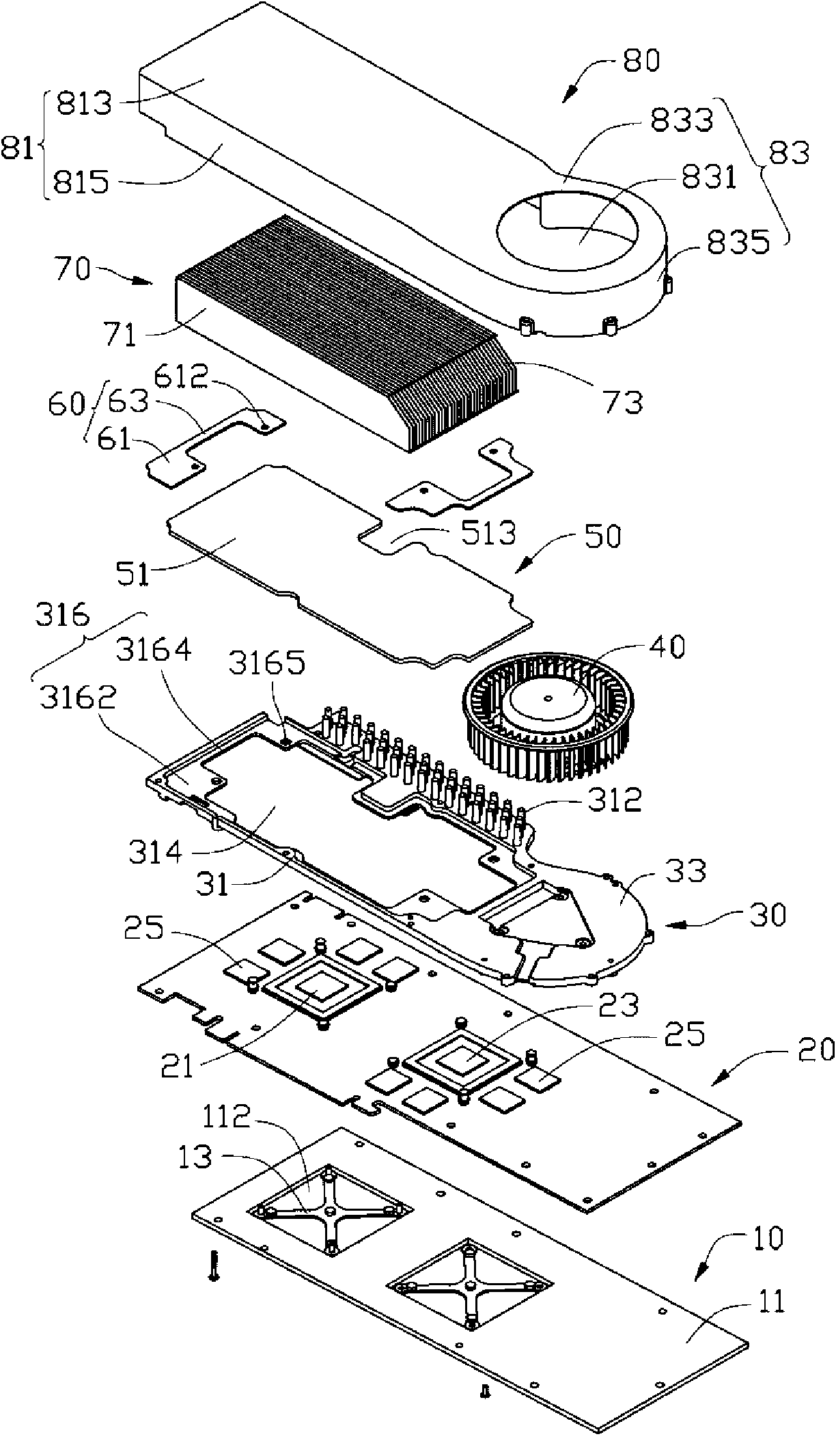

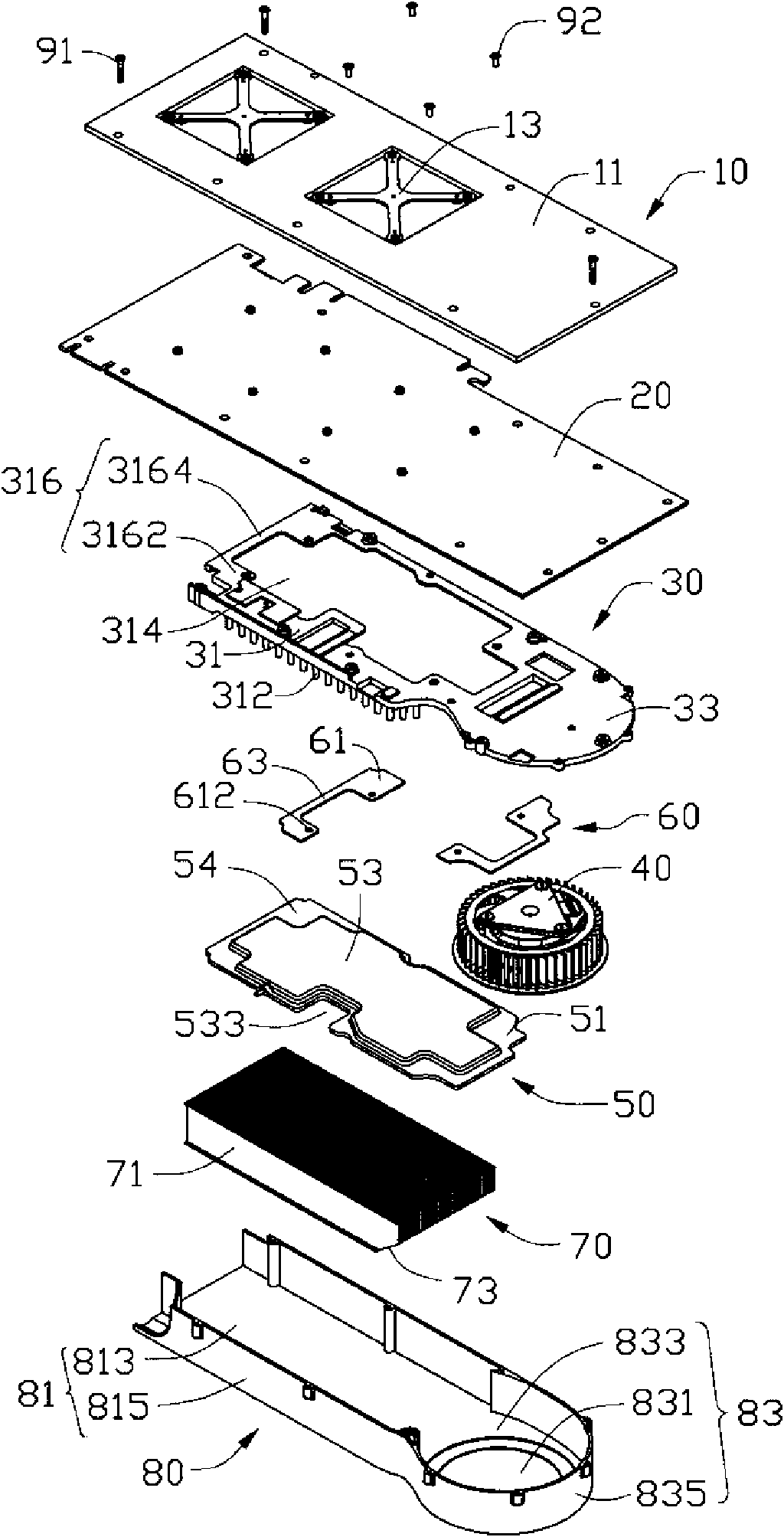

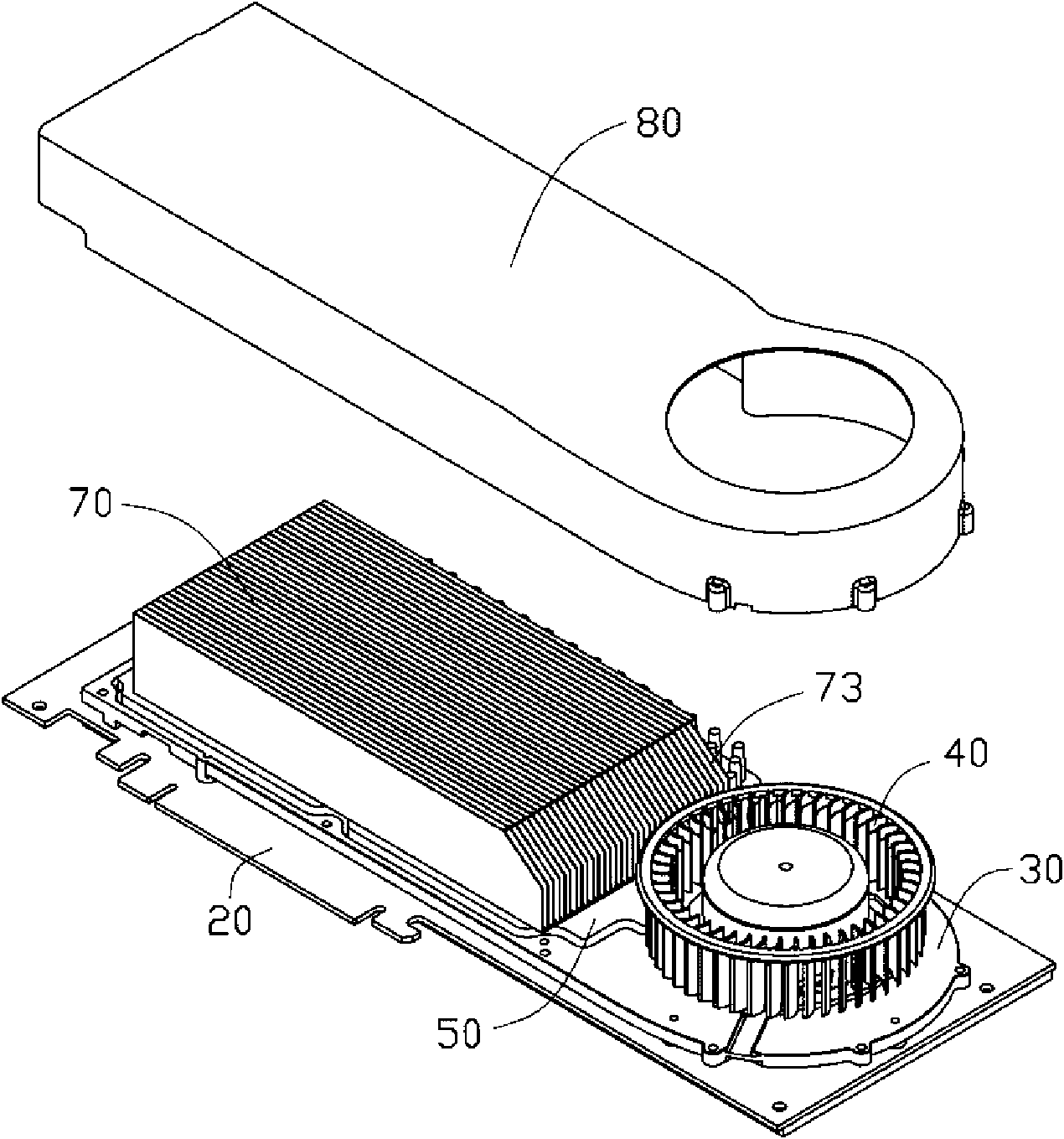

[0011] see figure 1 , which shows the heat dissipation device in a preferred embodiment of the present invention, the heat dissipation device is mainly used for a first heating electronic component 21 on the circuit board 20, a second heating electronic component 23 and respectively arranged on the first 1. Other electronic components 25 around the second heat-generating electronic components 21 and 23 dissipate heat. In this embodiment, the circuit board 20 is a video image card (VGA), the first and second heating electronic components 21, 23 are GPUs, and the power of the first heating electronic component 21 is higher than that of the second heating electronic component 23. High power.

[0012] The heat dissipation device includes a back plate 10 located below the circuit board 20, a bracket 30 located above the circuit board 20, a temperature equalizing panel fixed on the bracket 30 and attached to the first and second heating electronic components 21, 23 respectively. p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com