Improved connection structure between disk brake mounting board and wheel hub motor shaft

A hub motor and connection structure technology, which is applied in the direction of power devices, braking components, transportation and packaging, etc., can solve the problems of low installation accuracy, decreased disc brake braking effect, and increased cumulative error, so as to achieve stable braking performance and easy installation. Convenience, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

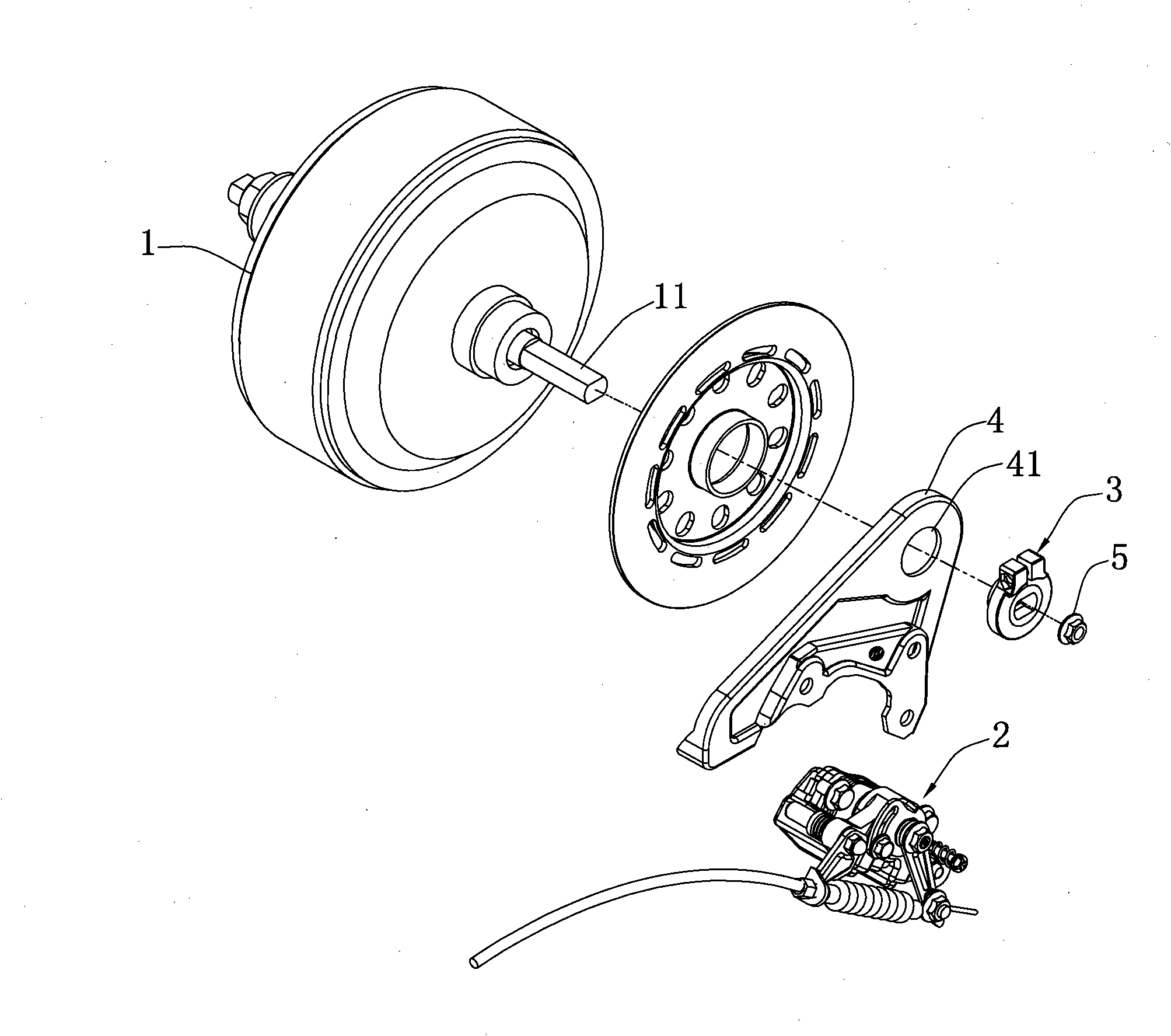

[0019] Such as figure 1 As shown, the present invention is a connection structure between a disc brake mounting plate and a hub motor shaft, including a disc brake assembly 2, a hub motor shaft 11 and a mounting plate for installing the disc brake assembly 2 on the hub motor shaft 11 4. The mounting plate 4 is provided with a mounting hole 41 for the hub motor shaft to pass through, the hub motor shaft 11 is provided with a positioning device, and the mounting plate 4 passes through the tightening mechanism 3 provided on the mounting hole 41 Lock on the positioning device.

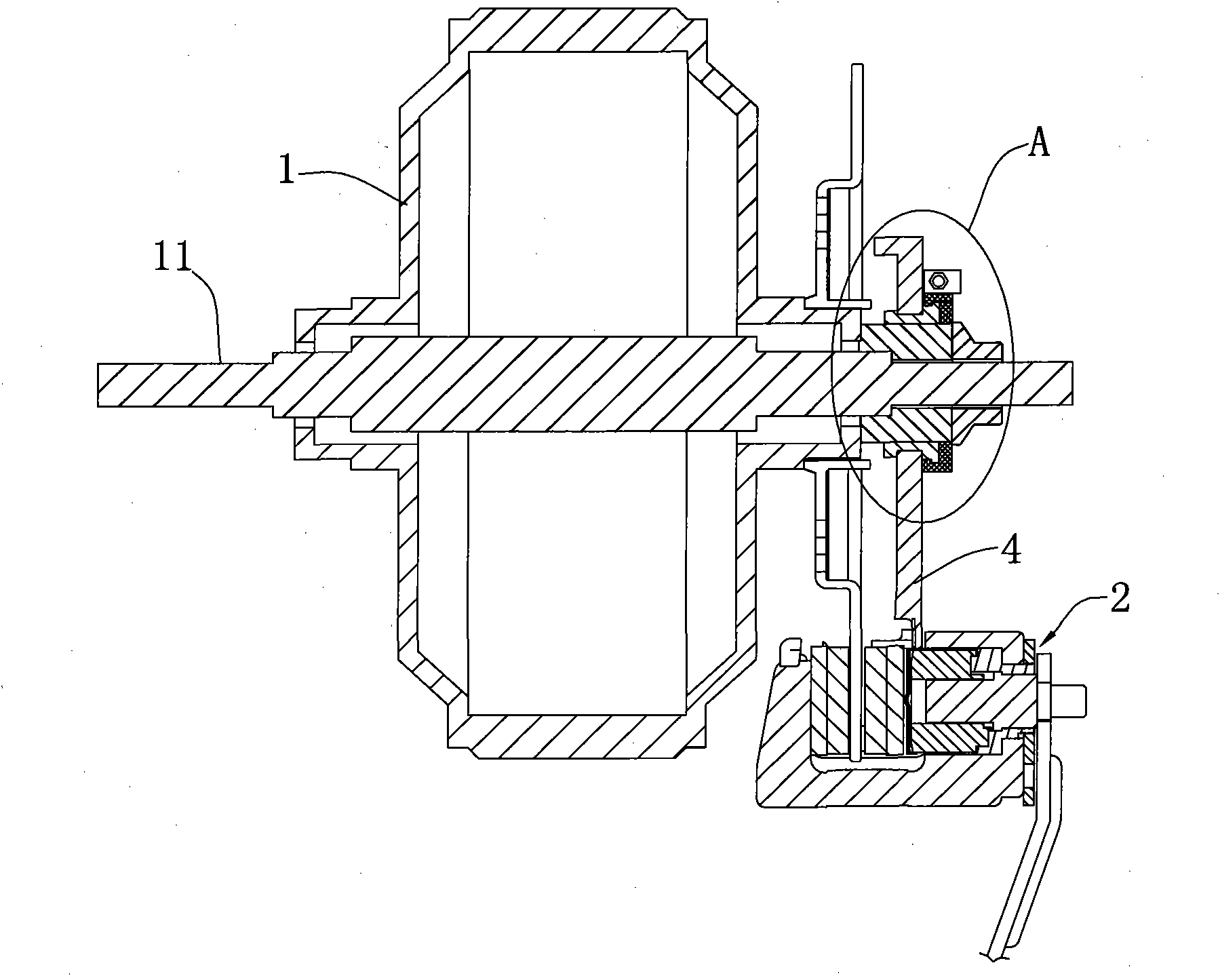

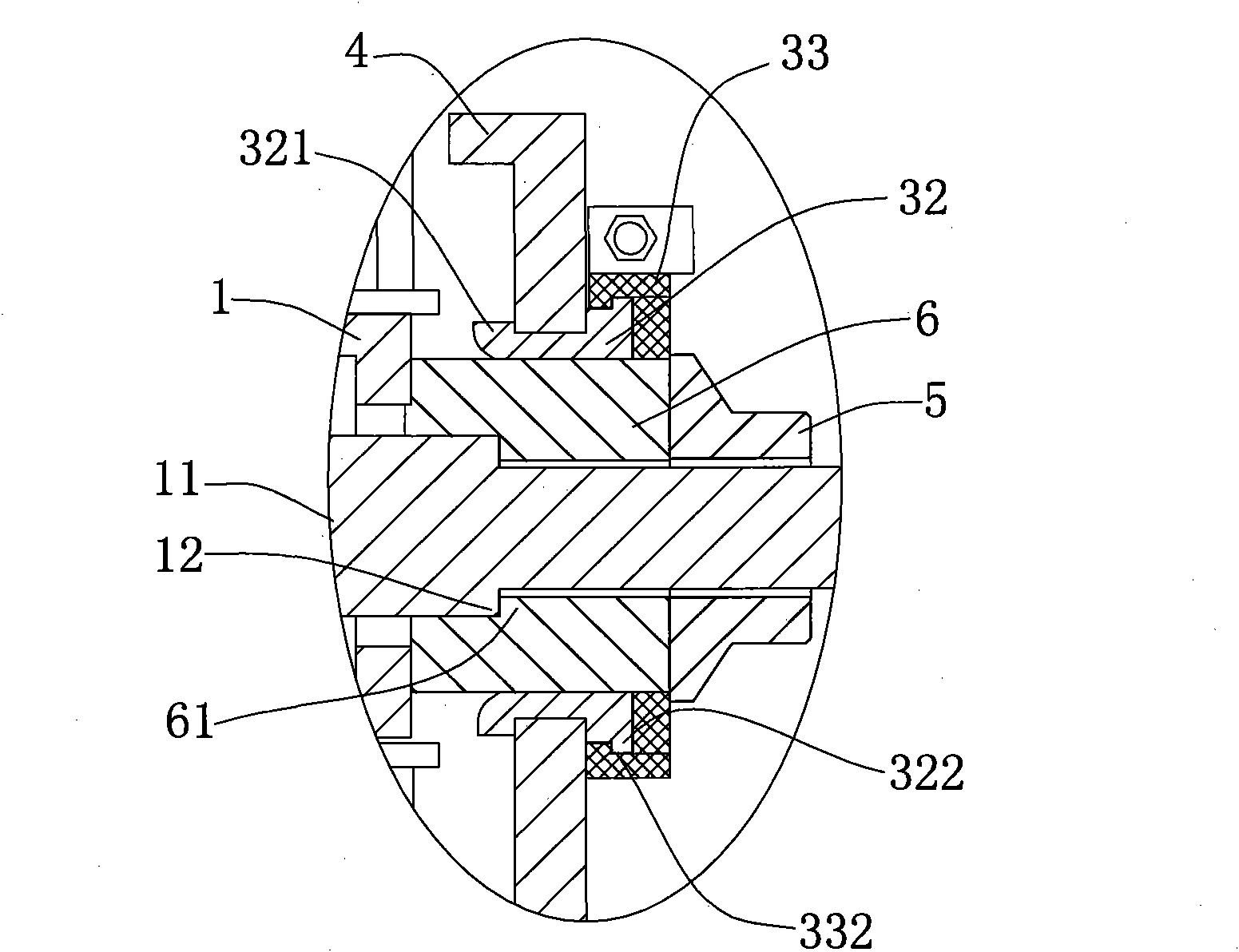

[0020] refer to Figure 2 to Figure 6 , a preferred embodiment of the present invention: the positioning device includes a shaft sleeve 6 and a lock nut 5 sleeved on the hub motor shaft 11, the shaft sleeve 6 is locked on the hub motor shaft 11 through the lock nut 5, and the shaft sleeve 6 The left end surface of the hub 1 abuts against the side of the hub 1; the hub motor shaft 11 is provided with a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com