Shell of electromagnetic wave resistivity instrument

A technology of resistivity and electromagnetic wave, which is applied in the shell field of electromagnetic wave resistivity instruments, can solve the problems of low precision, narrow application area, and difficulty in shell structure design, and achieve reliable shell sealing and high anti-vibration performance , The effect of receiving less interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

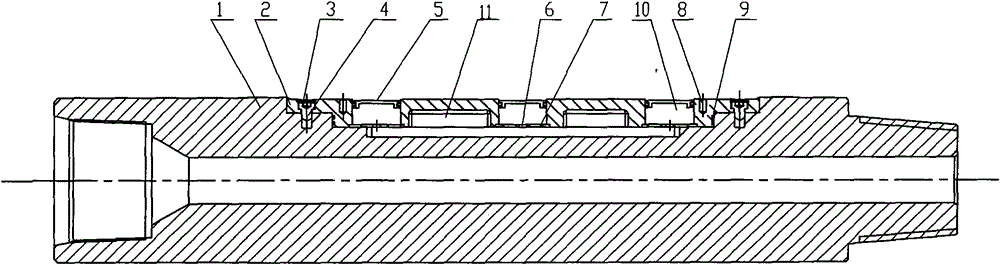

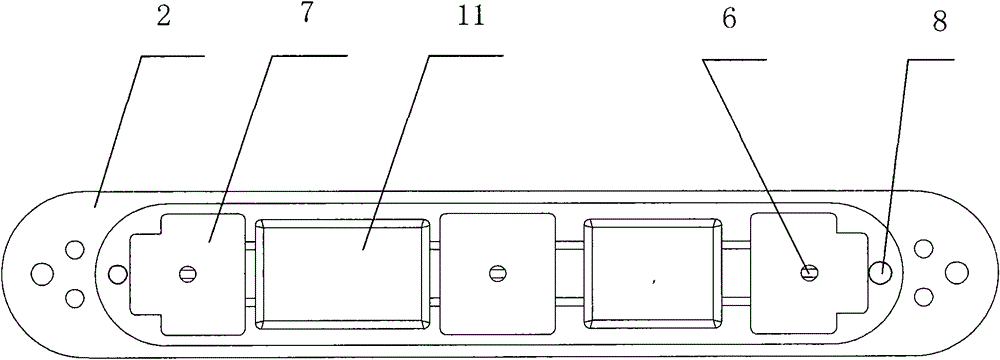

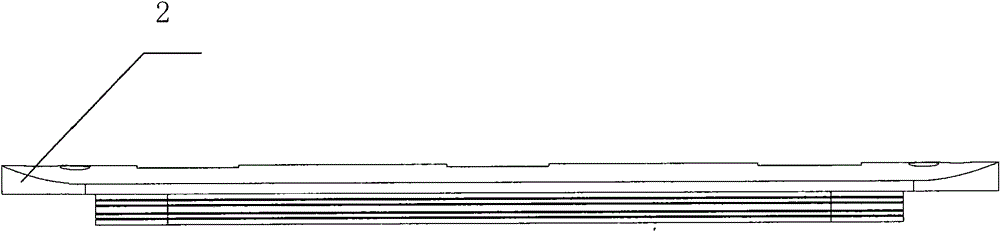

[0011] Below in conjunction with accompanying drawing, the present invention is further described: figure 1 As shown in , the shell of the electromagnetic wave resistivity instrument includes a short joint body 1, the outer wall of the short joint body 1 has a groove, and a buckle cover body 2 matching the shape around the groove is fixed in the groove, and the outer wall of the buckle cover body 2 is spaced Antenna slot 10 is arranged, and antenna rib 5 is installed on the upper opening of antenna slot 10, and bosses are left on the inner walls of both sides of antenna slot 10, and the bosses cooperate with concave antenna ribs 5 at both ends; the lower opening of antenna slot 10 Gasket 7 is installed, and transmitting and receiving antennas are installed in the antenna groove 10 below the antenna rib 5. After the antenna is installed, it is sealed with glue and supported by gasket 7 after sealing; there is a wiring hole 6 on the gasket 7, and the antenna The line is drawn fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com