Bearing cooling method and structure

A technology of motor bearings and fans, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

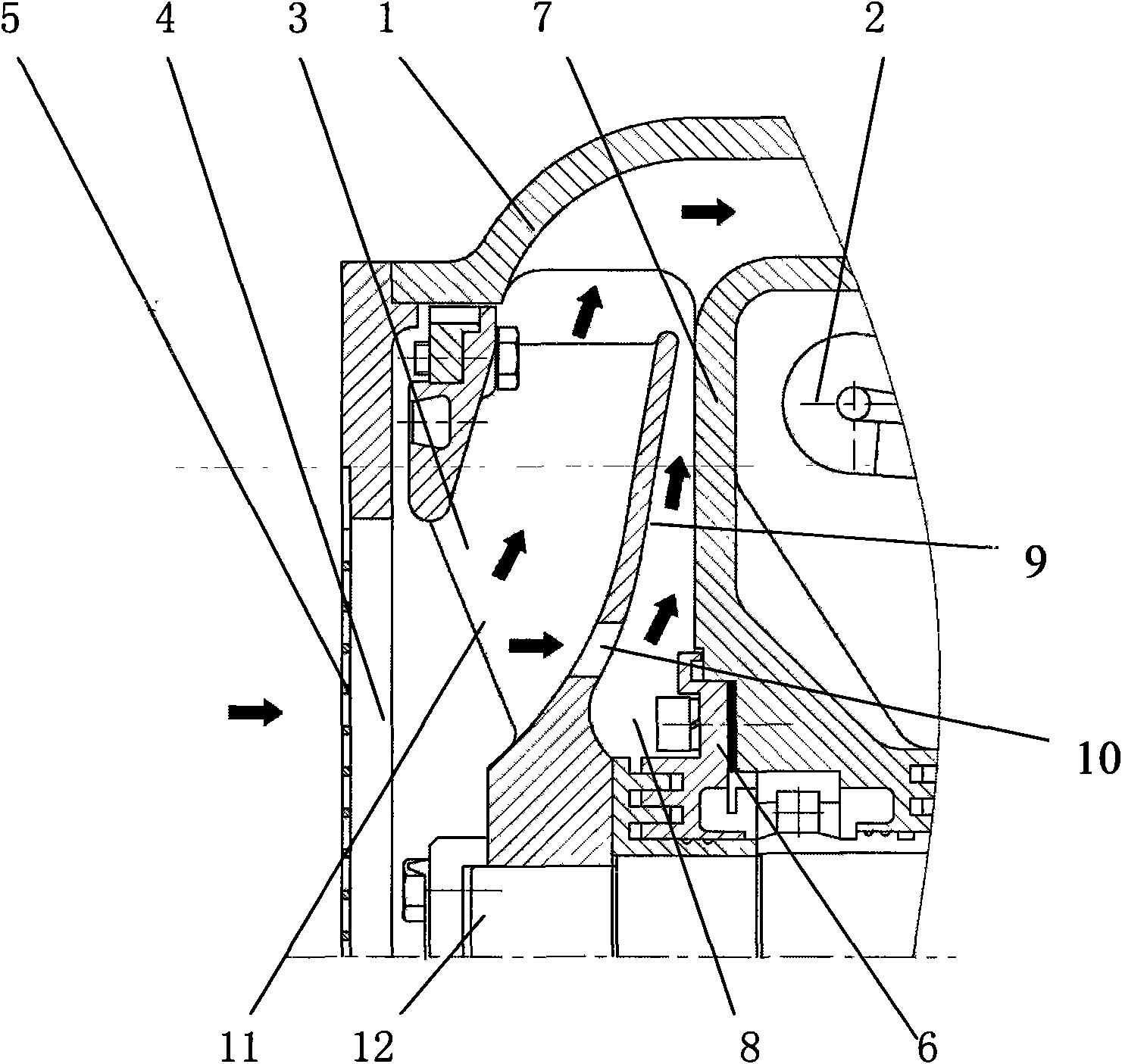

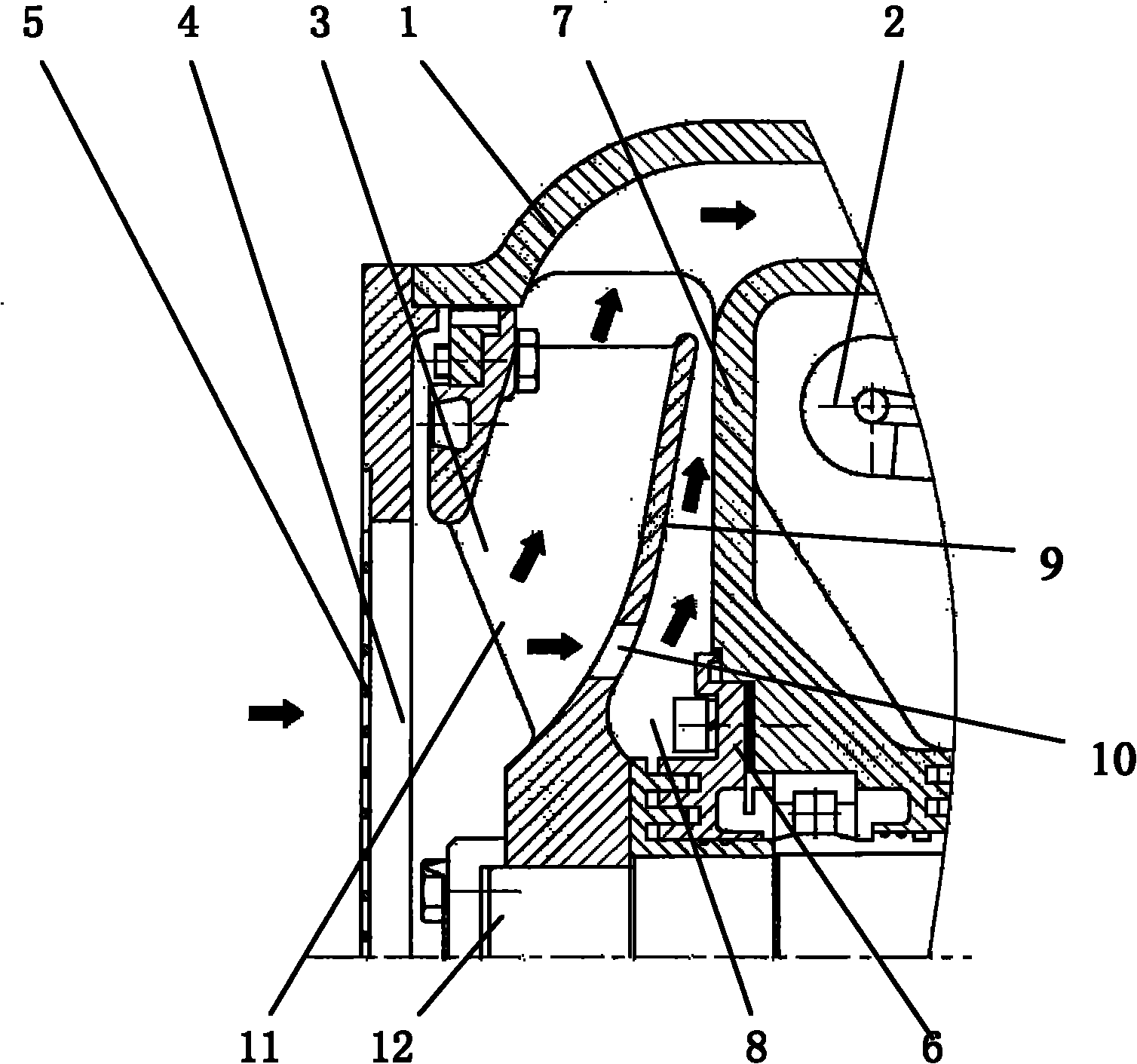

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

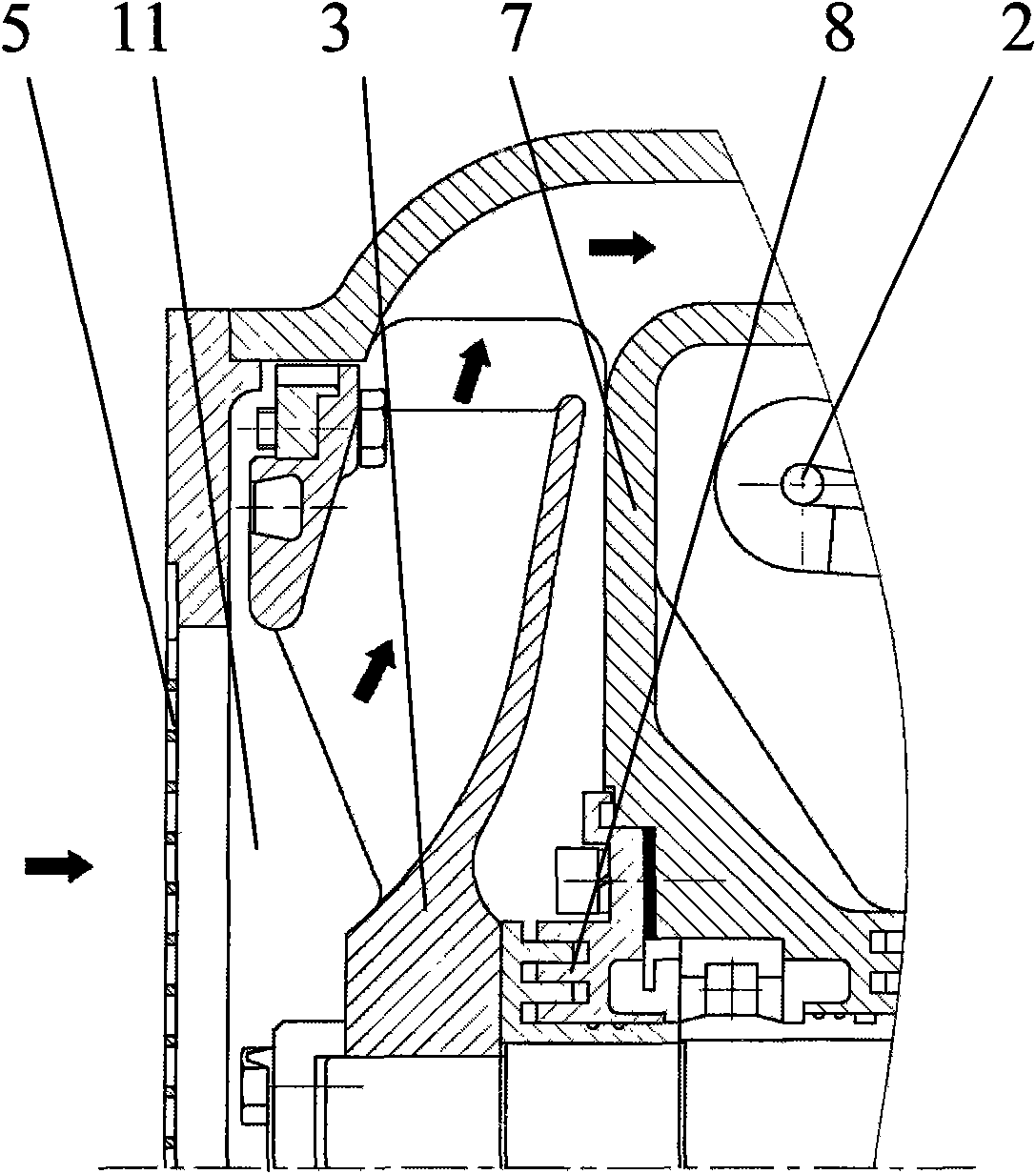

[0011] as attached figure 2 As shown, the present invention is a low-floor light rail vehicle traction motor bearing cooling method, which adopts a multi-channel air cooling method, and has a vent hole at the root of the fan inlet of the motor, and passes the cold wind entering the fan through the fan at the root of the fan inlet. Ventilation holes form multiple tributary airflows that enter the back of the fan blades, blow directly onto the end cover of the bearing, and then climb along the side of the stator frame and pass over the stator frame; the formed branches can be multiple branches, distributed in equal parts , After the multi-branch airflow enters the back of the fan, a cyclone vortex is formed on the back of the fan to cool the components at the bearing part to achieve more direct cooling of the motor bearing.

[0012] The low-floor light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com