Water-cooling supporting base

A support seat and water-cooling technology, applied to parts of thermometers, measuring devices, instruments, etc., can solve problems such as inability to achieve cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

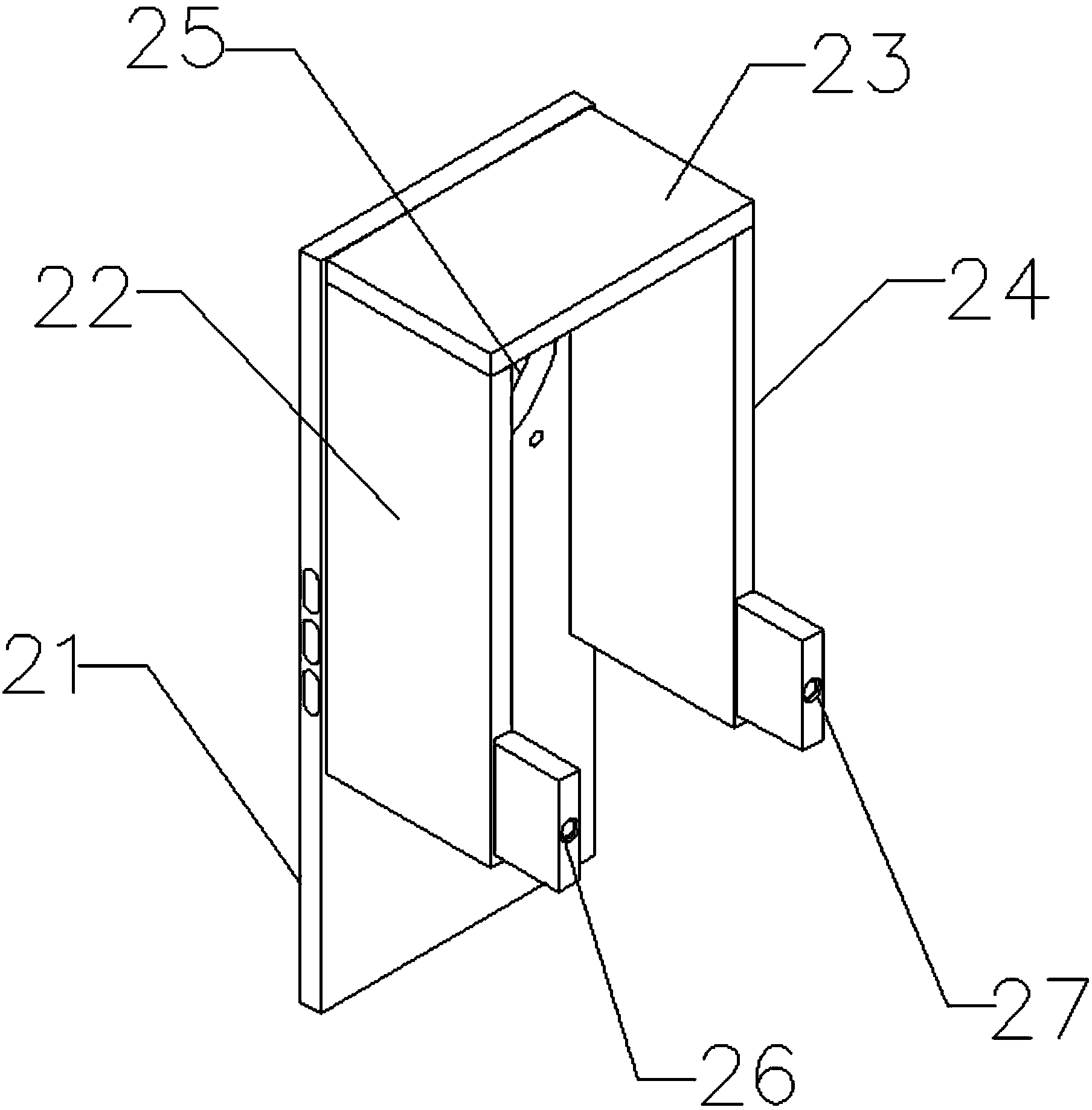

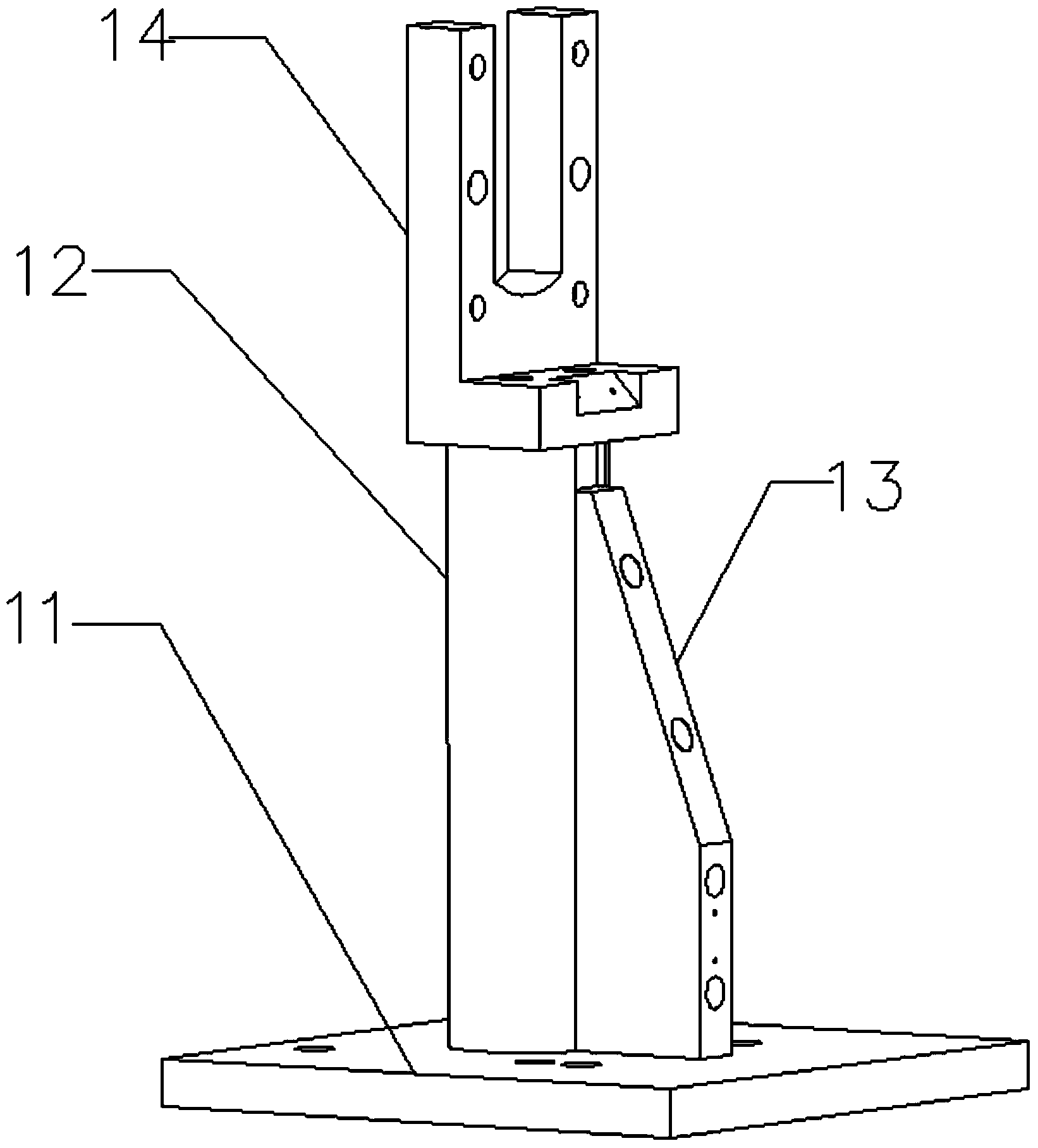

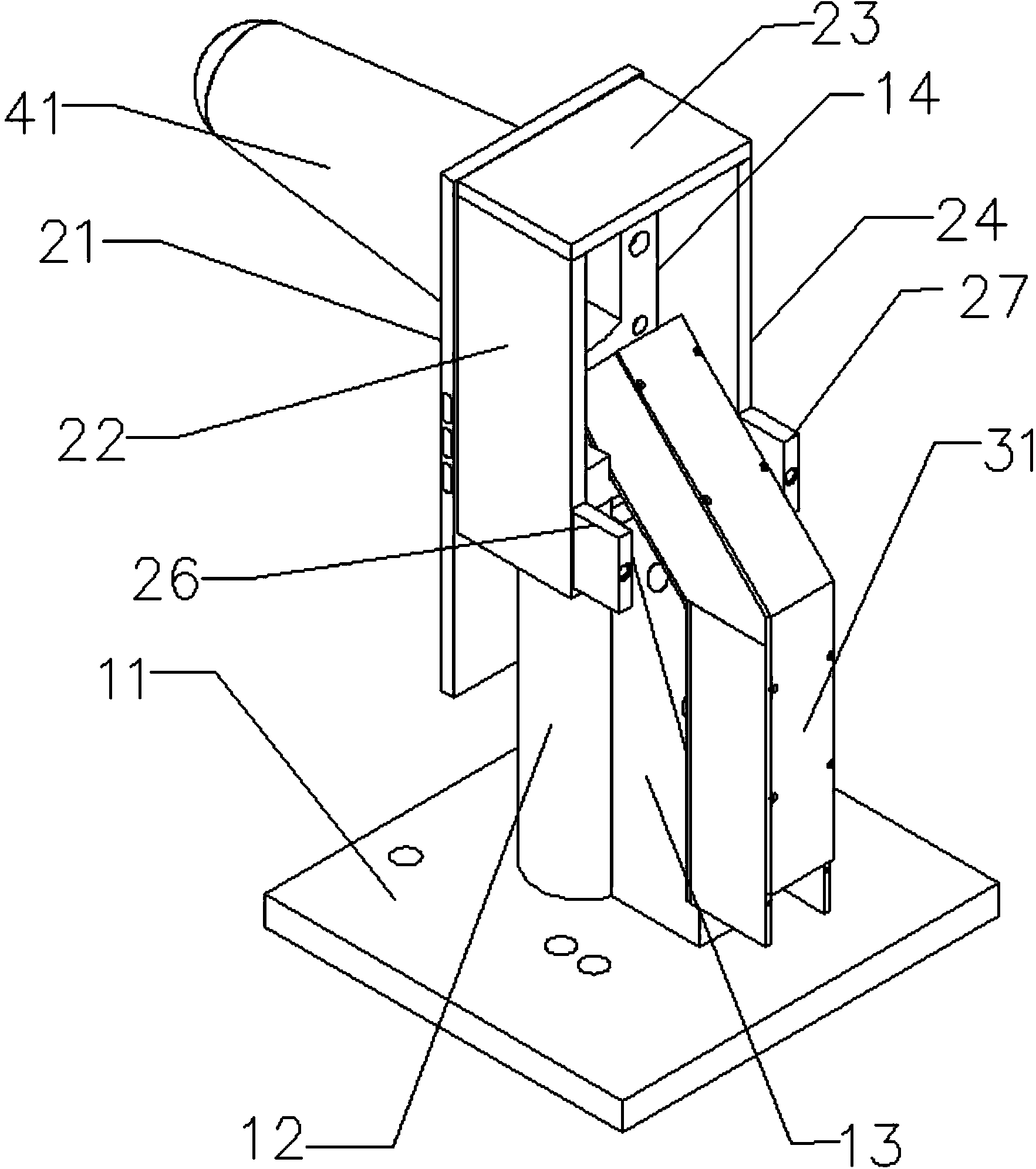

[0019] Such as figure 1 as shown, figure 2 with image 3 As shown, the present invention provides a water-cooled support base, comprising:

[0020] The mounting bracket has a base 11, a column 12 is installed on the base 11, a rib plate 13 is installed on the body of the column column; an upper fixing plate 14 is installed on the top of the column; a pipeline trough group is installed on the rib plate 13; an upper fixing plate 14 Heat sink is installed; heat sink, described heat sink comprises: front cooling plate 21, and front cooling plate has communicating hole 25; Out of the cold water plate 24, the upper cooling plate 23 is installed on the edge of the front cooling plate; the water inlet pipe connecting plate 26 is also installed on the left inlet cold water plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com