Device and method for forming voice tube of audiphone

A molding device, hearing aid sound technology, applied to hearing aids, sensors, tubular objects, etc., can solve the problems of high cost, sound tube deformation, low efficiency, etc., and achieve the effects of eliminating local deformation, simple processing, and easy heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

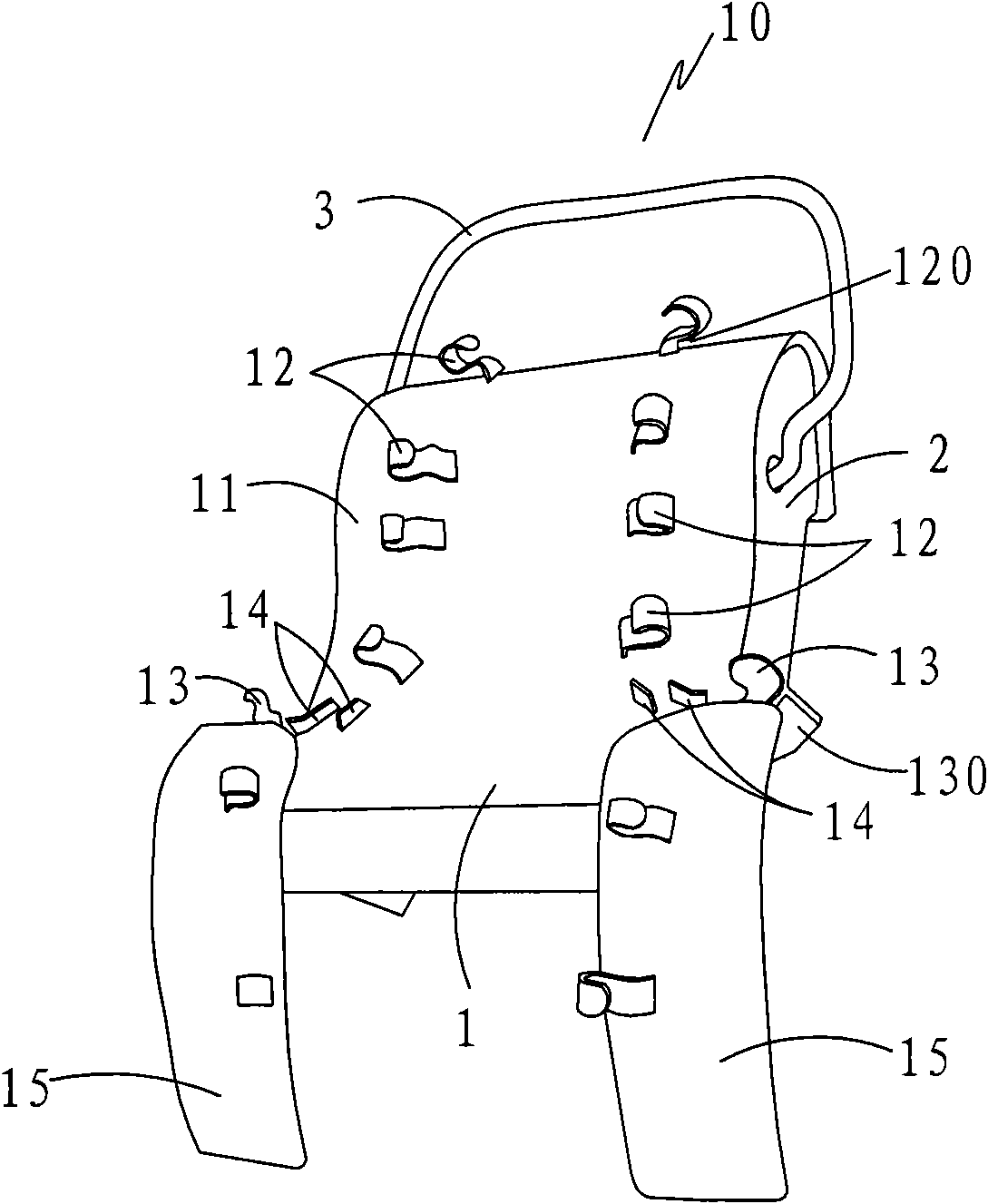

[0025] see image 3 and Figure 4 As shown, the forming device 10 for the acoustic tube of a hearing aid provided by the present invention includes a forming plate 1 and two baffle plates 2 for supporting the forming plate. And an operation handle 3, the two baffle plates 2 are respectively connected to the left and right sides of the forming plate 1 and have a certain angle with the forming plate 1. The operation handle 3 is connected to the top of the forming plate 1 for convenient operation during heating or cooling.

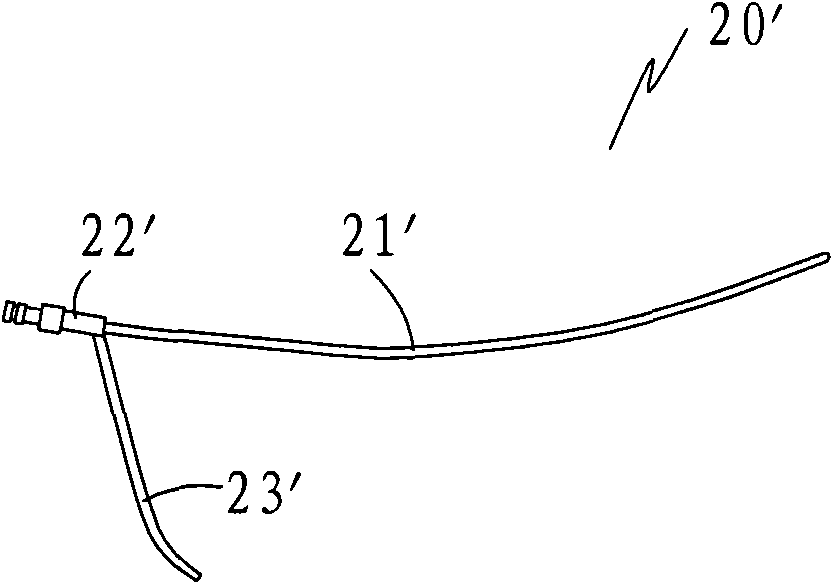

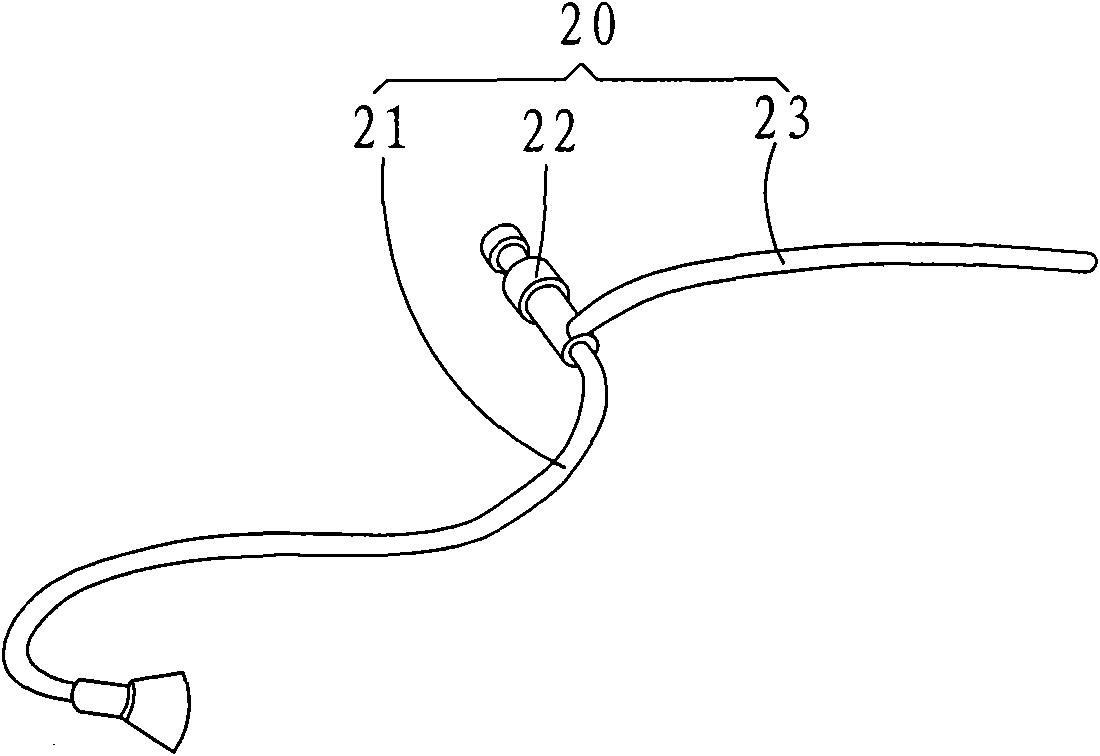

[0026] Please also see Figure 1 to Figure 4 As shown, the forming plate 1 has a curved surface 11, the curved surface 11 has the same predetermined shape curvature as the standard sound tube 20, a row of positioning compression springs 12 are respectively arranged on the left and right sides of the curved surface 11, and the positioning compression springs 12 are S type, there is a semicircular gap 120 between it and the curved surface 11 , and the size o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap