Closed coaxial differential arch dental roller

A technology of rollers and bow teeth is applied in the field of closed coaxial differential bow teeth rollers, which can solve the problems of large volume and complex structure, and achieve the effects of reliable operation, solving the problem of uncleanness and good working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

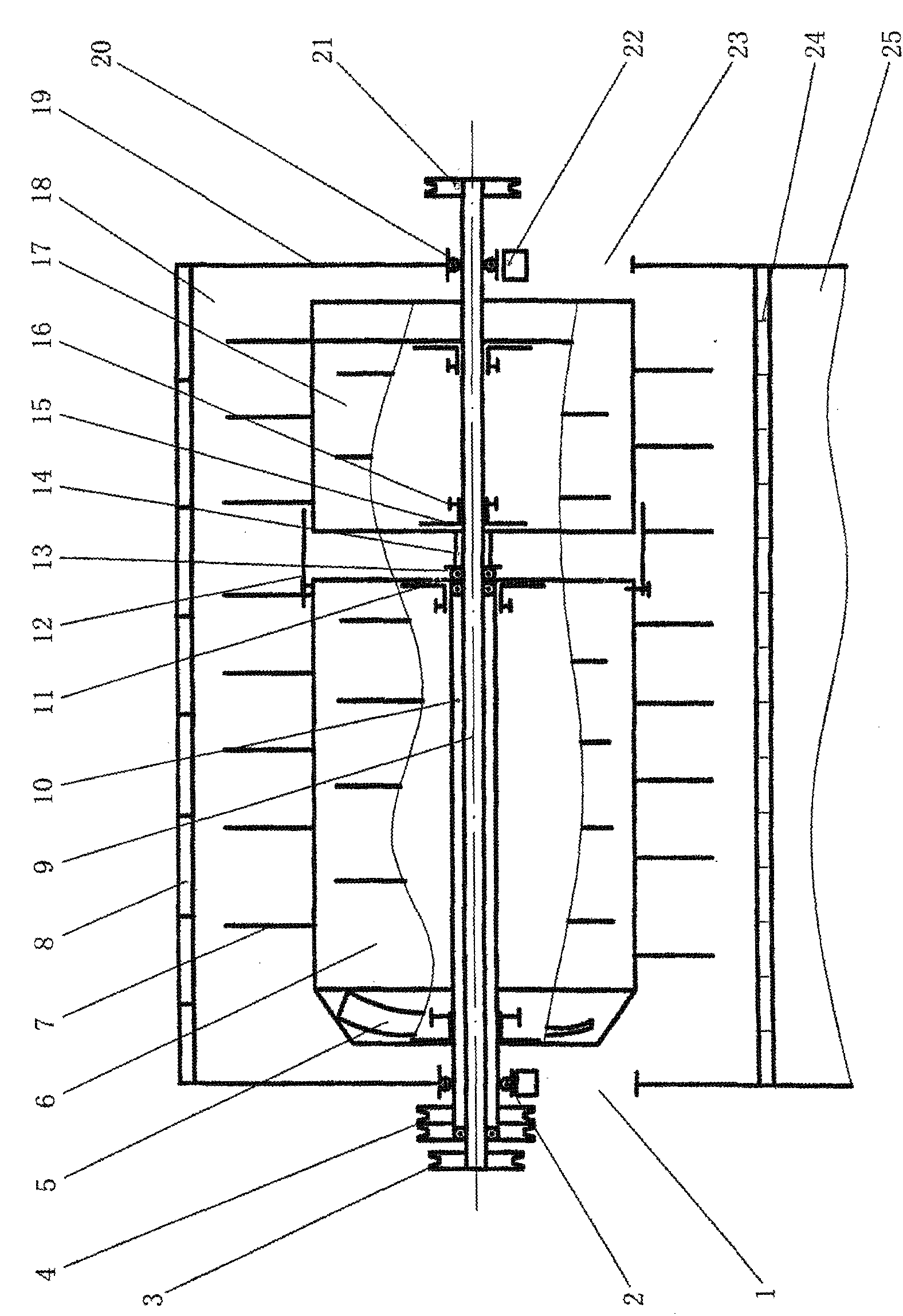

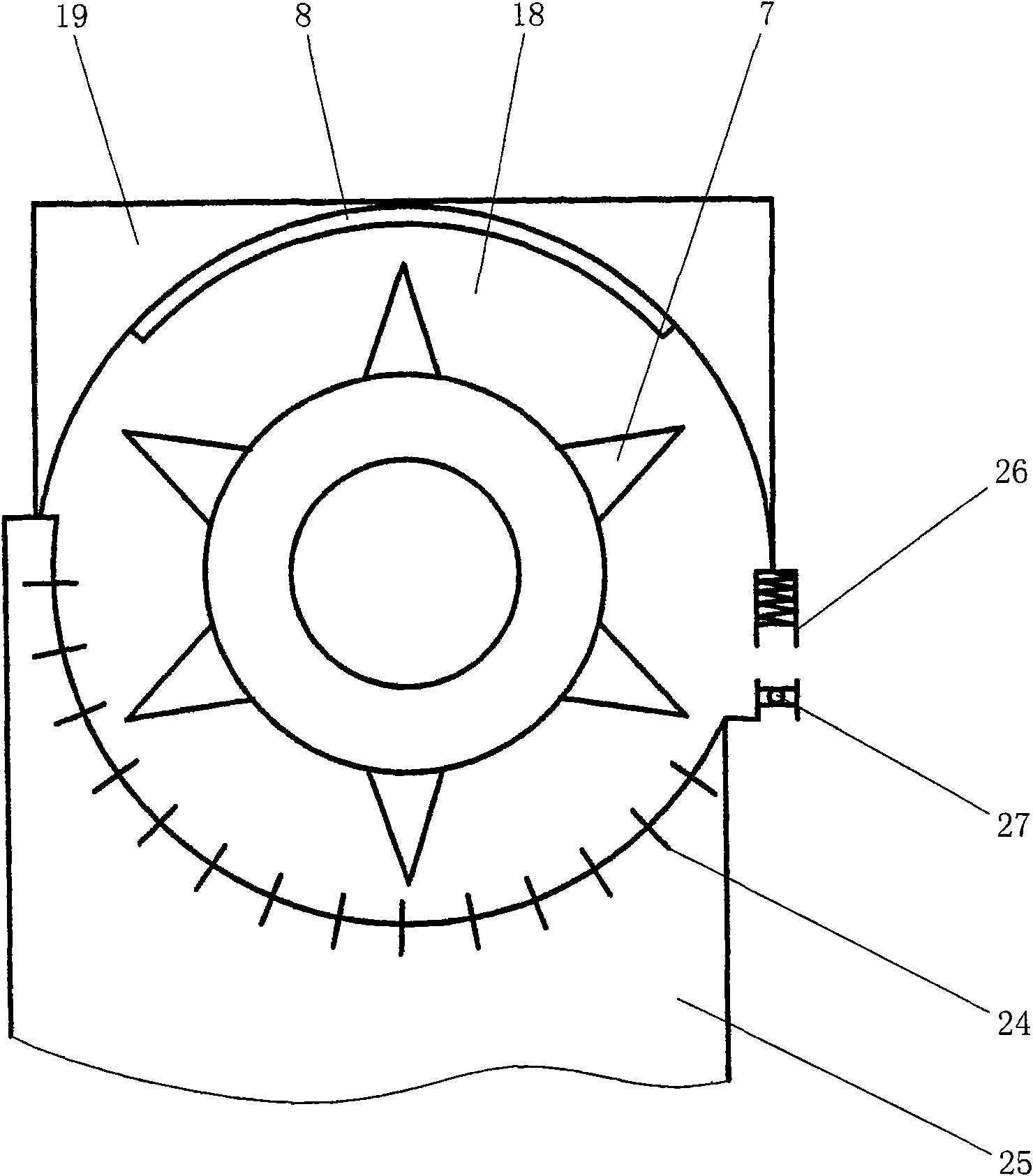

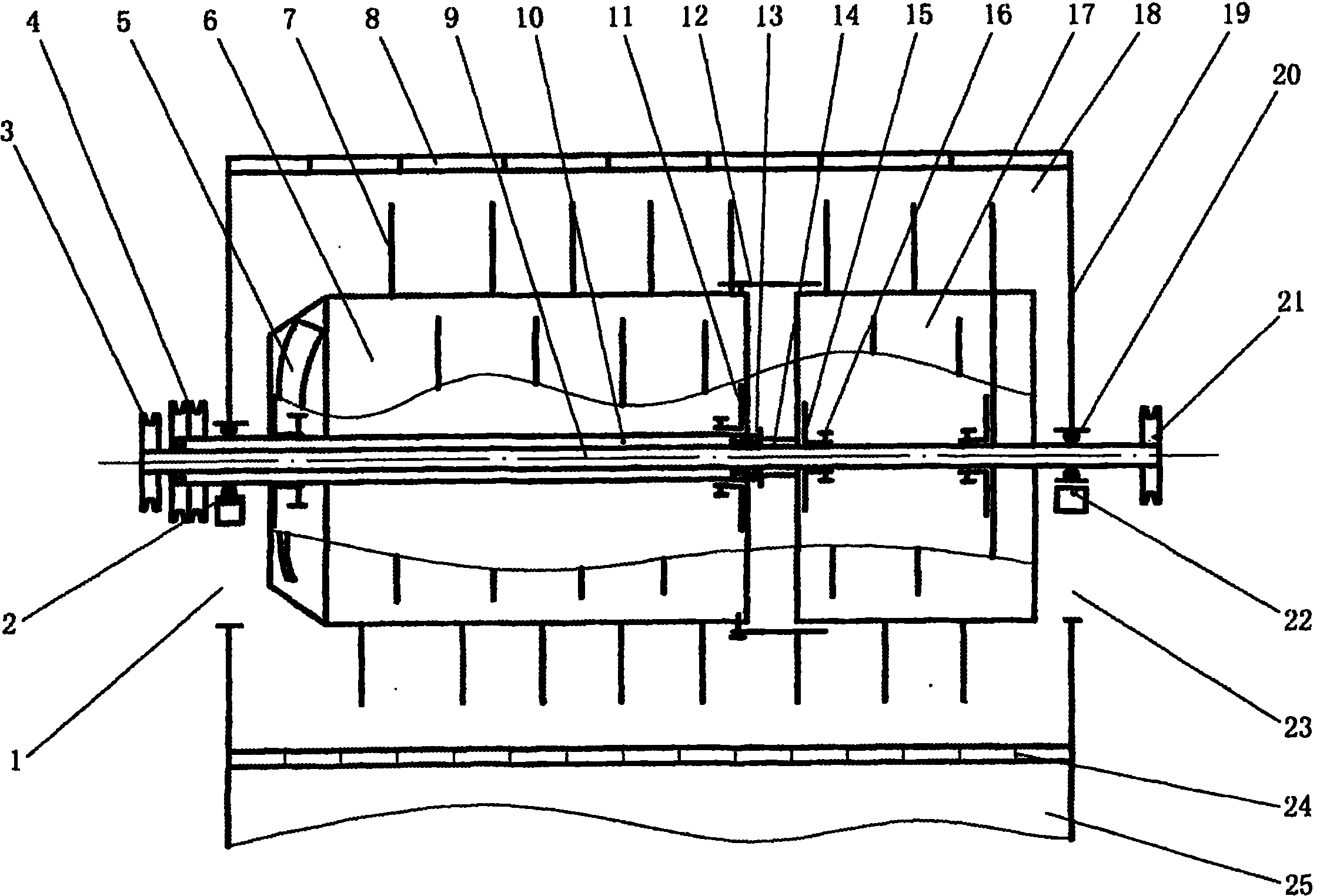

[0011] Refer to attached figure 1 And attached figure 2 , a closed coaxial differential bow teeth drum for half-feeding rice-wheat combine harvester and half-feeding rice-wheat thresher, the drum includes a closed low-speed drum 6, a closed high-speed drum 17, a hollow shaft 10 And the drum shaft 9, wherein, the two ends of the low-speed drum 6 are respectively provided with a flange-11, the flange-11 is fixed with the low-speed drum 6, and the flange-11 is fixed on the hollow shaft by a set screw 16 10, the head of the low-speed drum 6 is in the shape of a truncated cone, and the head of the low-speed drum 6 is equipped with an introduction piece 5, and several bow teeth 7 arranged in a spiral line are arranged on the cylindrical surface of the low-speed drum 6; The two ends of the drum 17 are respectively provided with a flange two 15, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com