Chromium slag detoxification method

A technology for chromium slag and slag slurry, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost, inability to completely solve the detoxification of chrome slag, etc. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Chromium slag composition: the proportion of each component in chromium slag SiO 2 : 58.92%; CaO: 26.92; MgO: 8.48%; Fe 2 o 3 : 5.64%; Al 2 o 3 : 12.42%; Cr 2 o 3 : 3.21%.

[0037] Detoxify the above chromium slag:

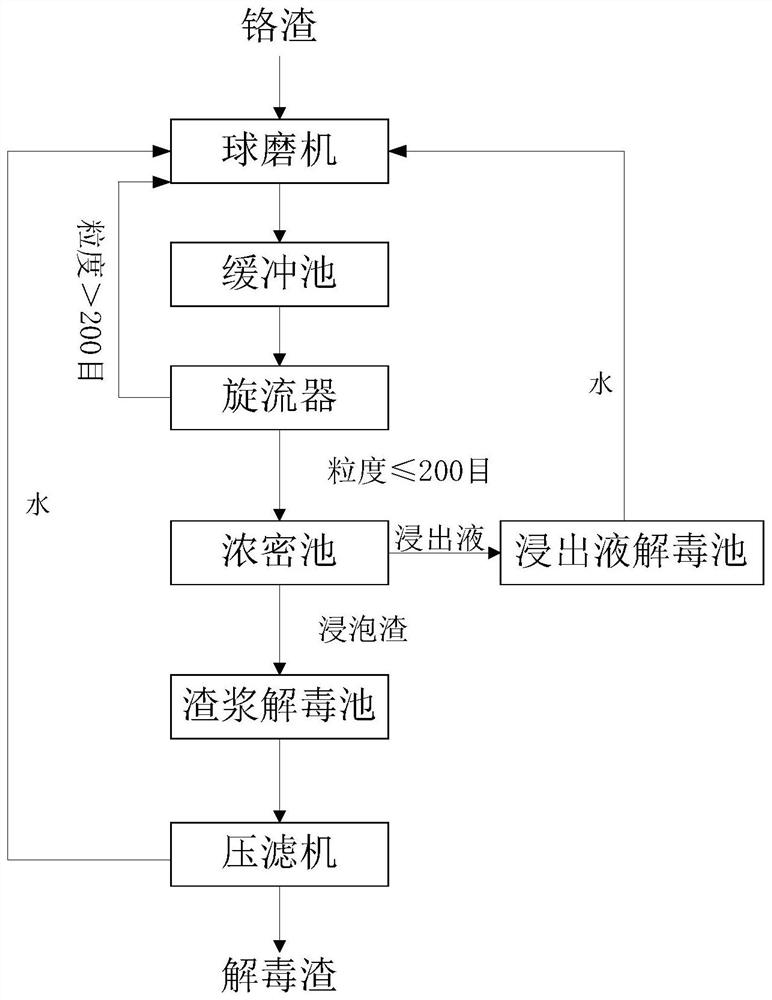

[0038] The above-mentioned chromium slag and water are mixed and put into a ball mill for grinding treatment, and a solubilizing agent sodium bicarbonate is added at the same time of the grinding treatment to obtain a slurry. Among them, the weight ratio of chromium slag to water is 3:7; the dosage of solubilizer is 0.8% of the weight of chromium slag; the grinding fineness of the slurry is 200 mesh.

[0039] The above slurry is added to the buffer tank for buffer treatment, and then the slurry is separated and screened through a cyclone. Put the slurry with a particle size of ≤200 mesh into the thickening tank for soaking, and soak for 8 hours to obtain the leachate and soaking residue; return the slurry with a particle size of >200 mesh to the bal...

Embodiment 2

[0043] The difference from Example 1 is only that the dosage of the solubilizing agent is 1.5% of the weight of the chromium slag. The chromium ion leaching rate is 88.5%.

Embodiment 3

[0045] The only difference from Example 1 is that the weight ratio of water and slurry in the thickening tank is 70:3. Chromium ion leaching rate is 82.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com