Apparatus for preventing dummy of glass panel from falling down

A technology of glass panels and air openings, which is applied in glass cutting devices, glass manufacturing equipment, transportation and packaging, etc., and can solve problems such as reduced production, uneven cutting surfaces, and fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

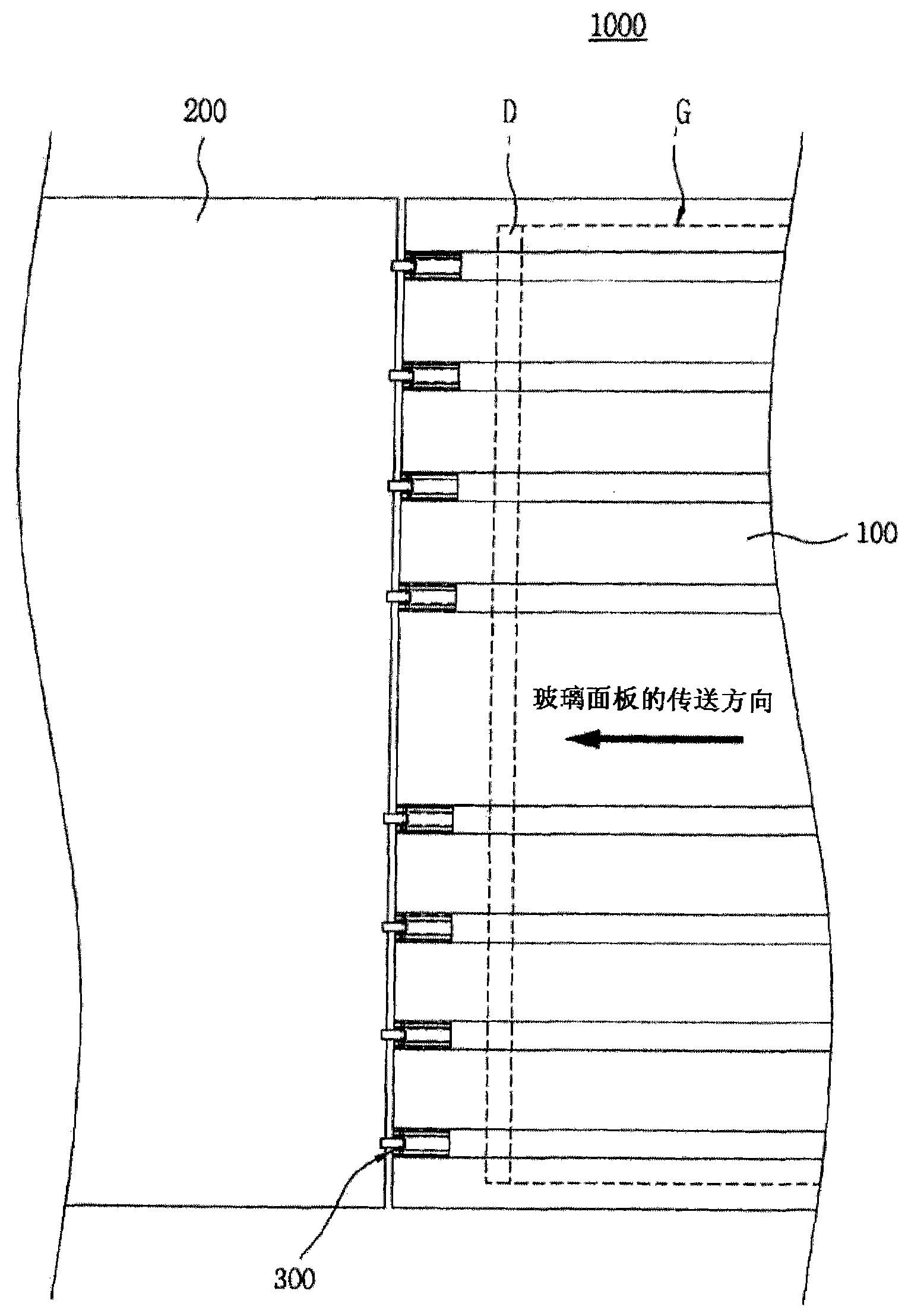

[0038] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement the present invention. Before describing the exemplary embodiments of the present invention, it should be understood that "front" is defined as a forward direction with respect to the conveying direction of the glass panel, and "rear" is defined as a rearward direction with respect to the conveying direction of the glass panel.

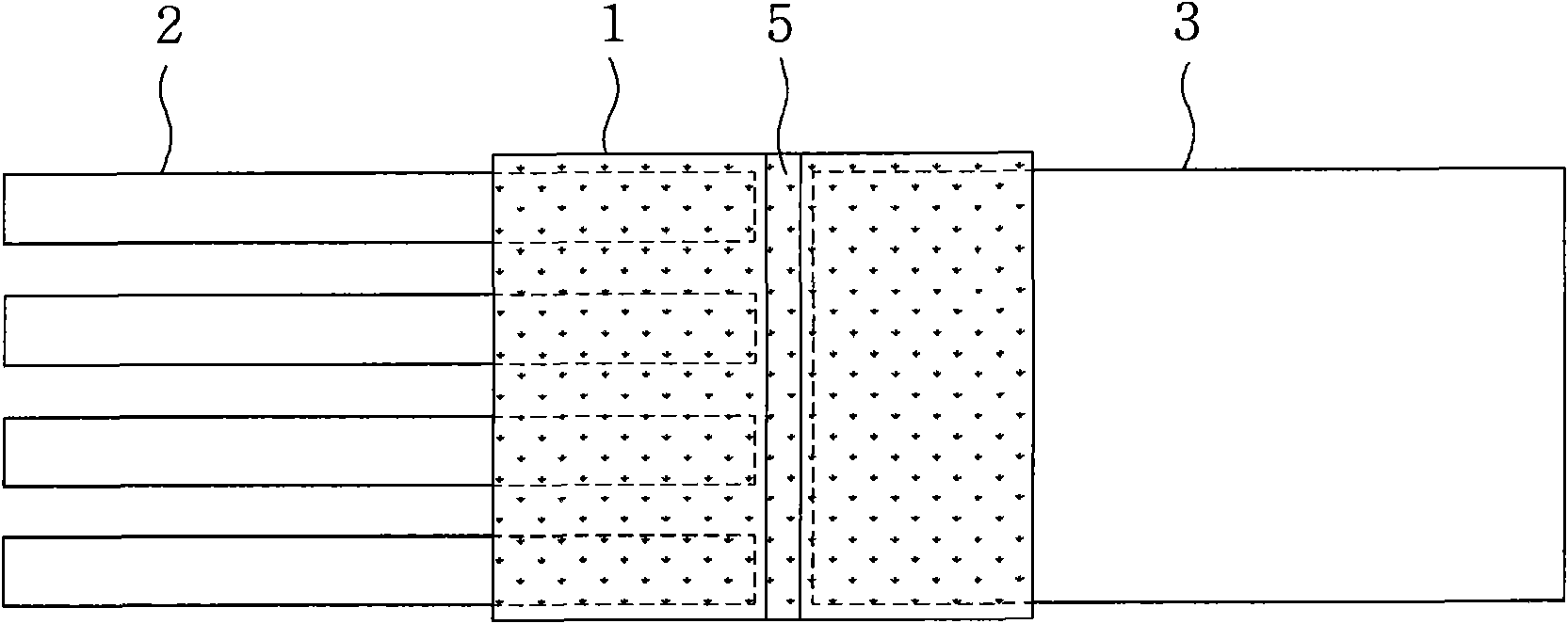

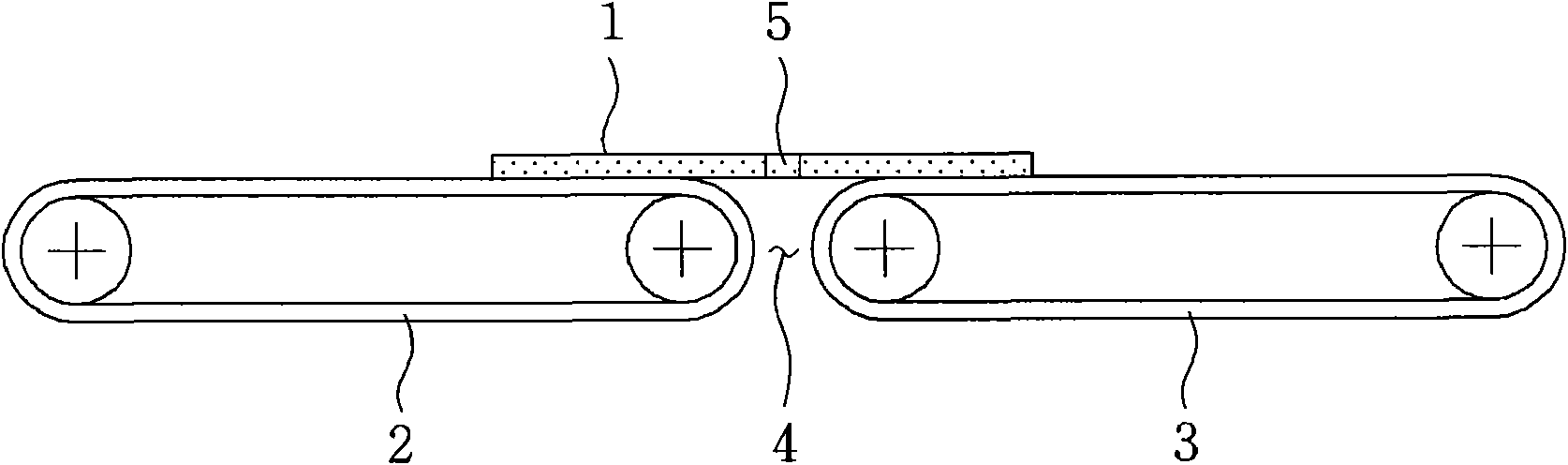

[0039] figure 2 is a plan view illustrating a device for preventing an opening of a glass panel from falling according to an exemplary embodiment of the present invention, image 3 is showing figure 2 A side sectional view of a part of Figure 4 is a perspective view showing a bridge according to an exemplary embodiment of the present invention, Figure 5 is showing Figure 4 An exploded perspective view of part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com