Array solid hydrogen storage and discharge device

An array type, hydrogen storage technology, applied in fixed-capacity gas storage tanks, container discharge methods, gas/liquid distribution and storage, etc., can solve the problem of small single capacity of metal hydride hydrogen storage tanks, and achieve filling capacity Higher, lower cost, and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

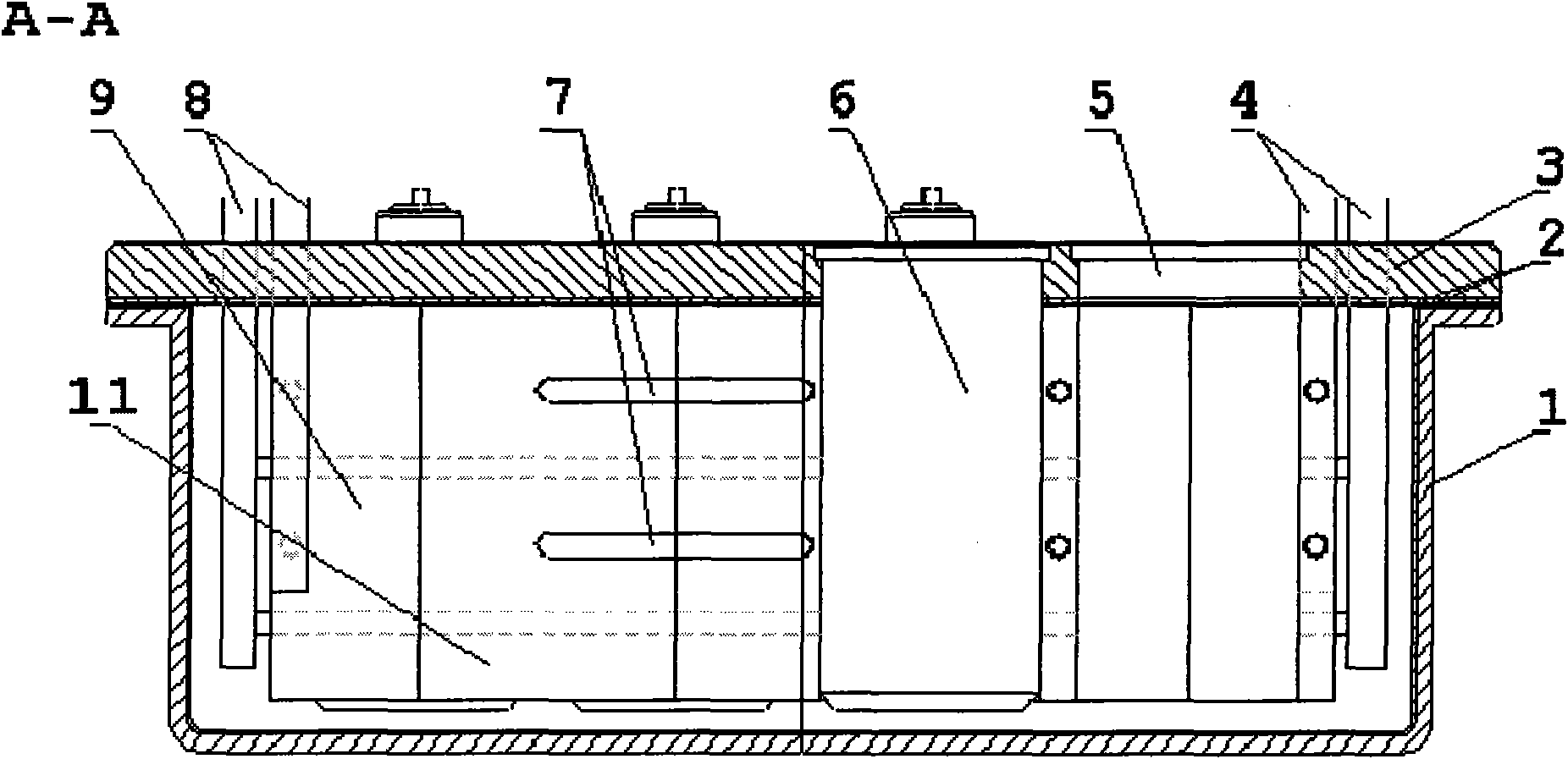

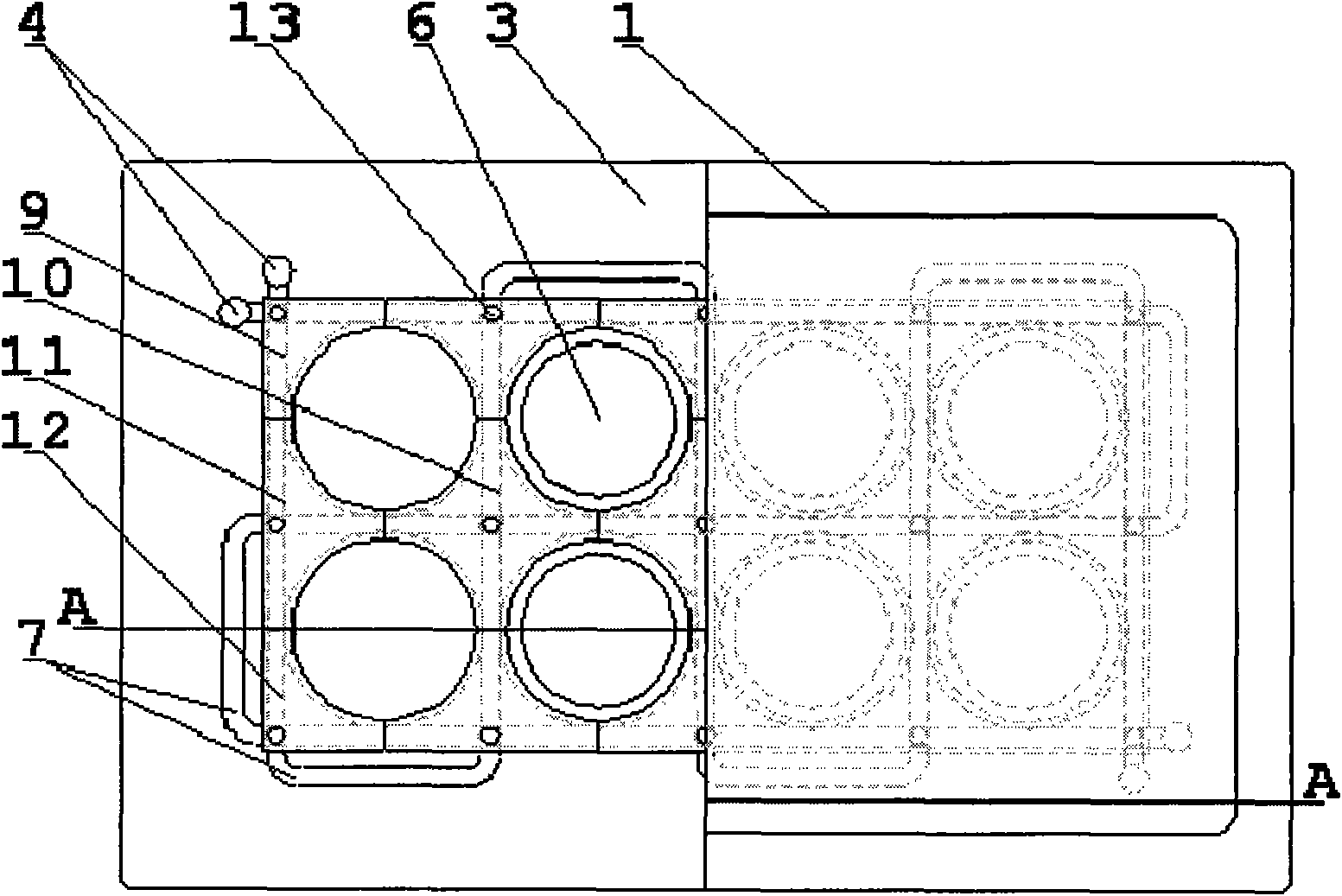

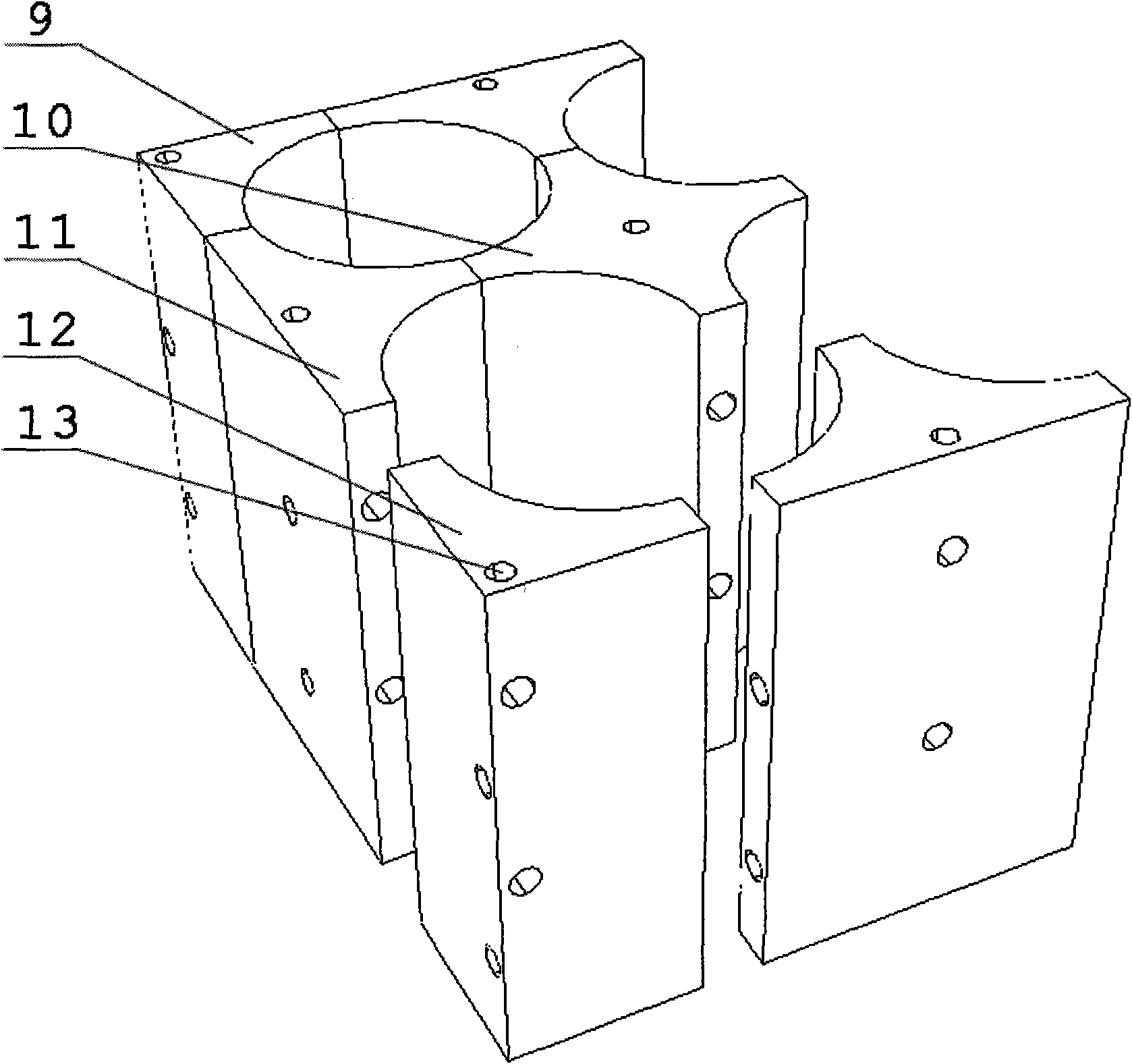

[0019] refer to figure 1 , figure 2 , an array type solid-state hydrogen storage and dehydrogenation device is a sealed cavity composed of an outer cavity lower cover 1, an outer cavity upper cover 3, and a heat insulation layer 2 attached to the outer cavity lower cover 1 and the outer cavity upper cover 3. The body is provided with a hydrogen storage tank installation port 5 which has the functions of solid-state hydrogen storage and hydrogen discharge. The cavity is provided with a detachable first cooling block 9 made of copper, aluminum or aluminum alloy with good thermal conductivity. The heat dissipation block 10, the third heat dissipation block 11, and the fourth heat dissipation block 12 are used as the supports of the hydrogen storage tanks, and the groups of cylindrical hydrogen storage tanks 6 that can be increased or decreased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com