T-shaped longitudinal micro-channel cold plate with inclined channels

A technology of inclined channels and micro channels, which is applied in the field of electronic information, can solve the problems of cold plate temperature uniformity and flow distribution unevenness, and achieve the uniform temperature of the heating surface and the enhancement of heat transfer efficiency, enhanced heat transfer efficiency, and enhanced mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through embodiments in conjunction with the accompanying drawings.

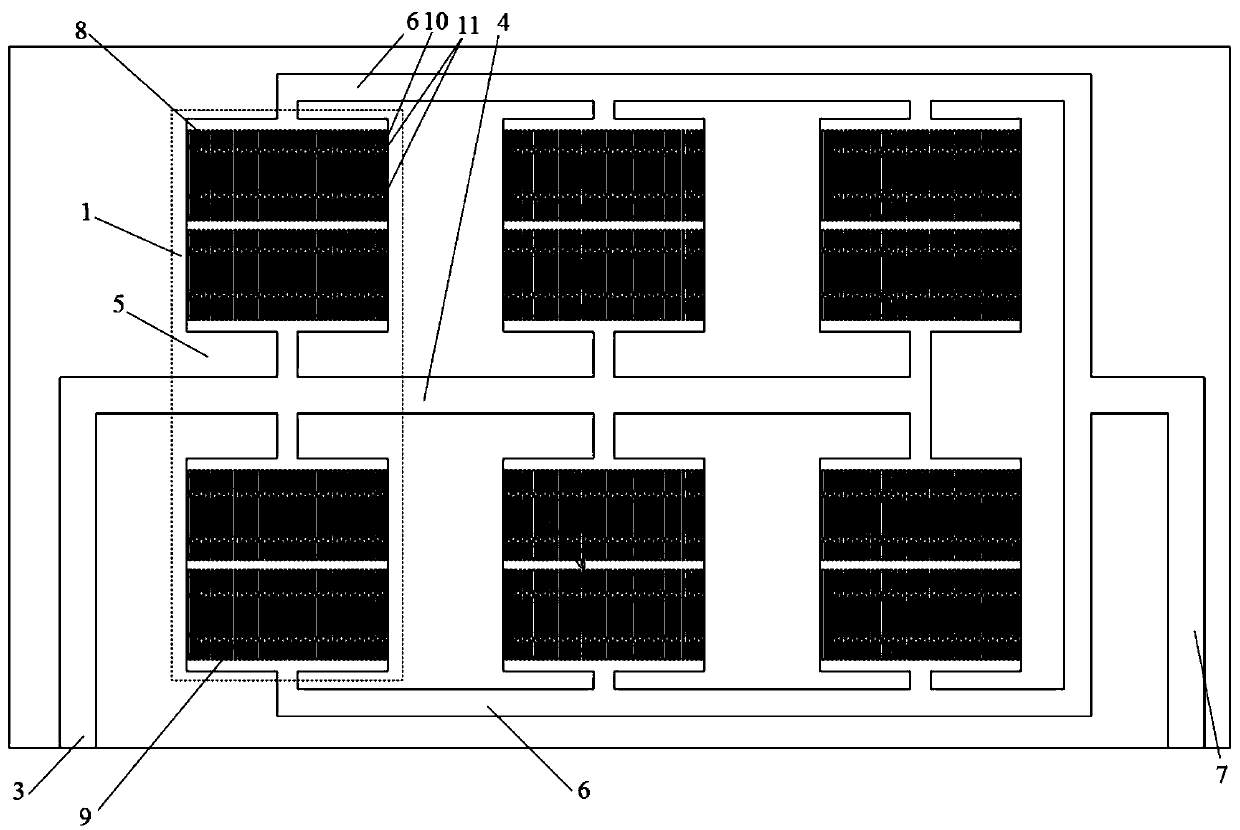

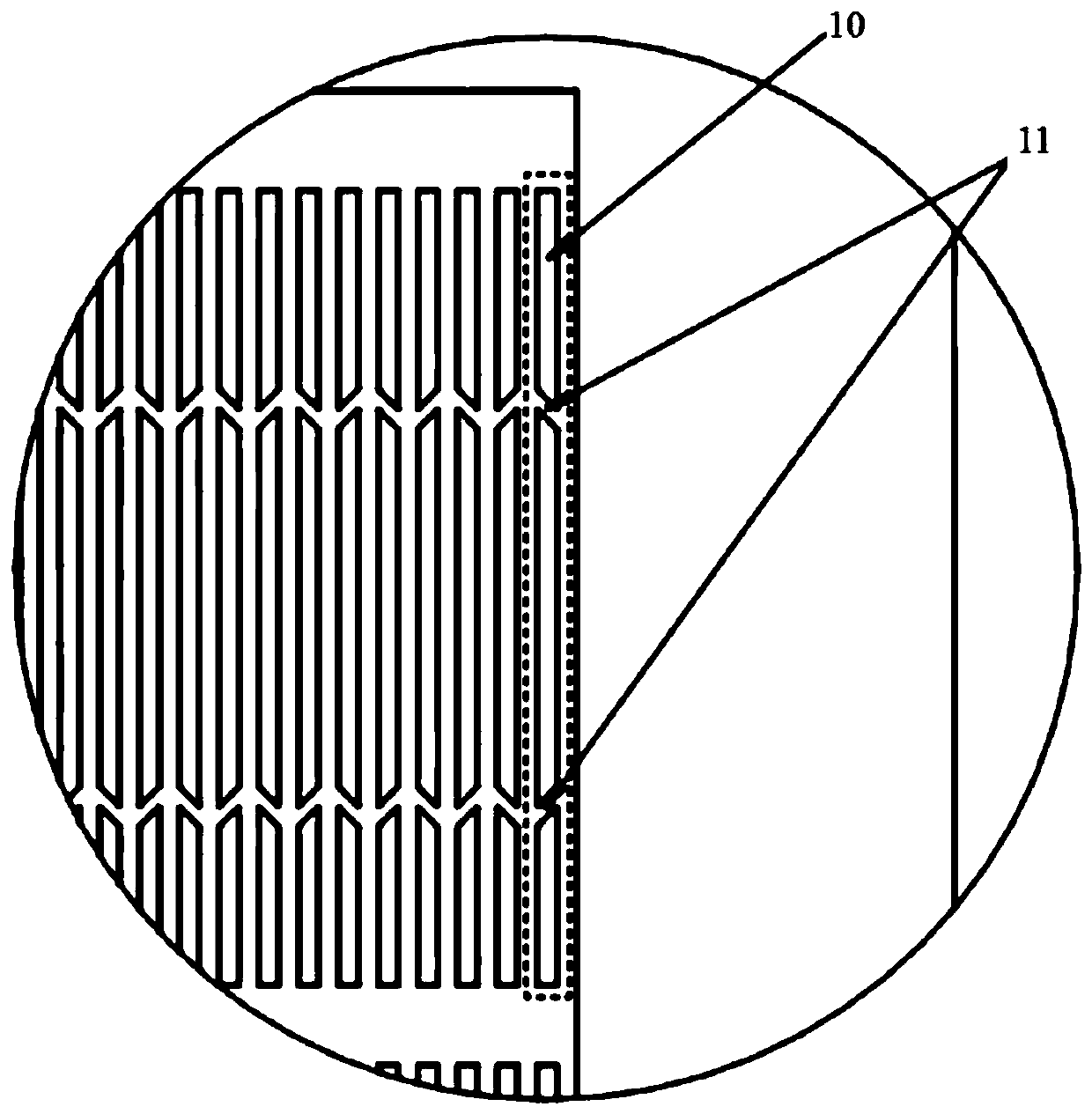

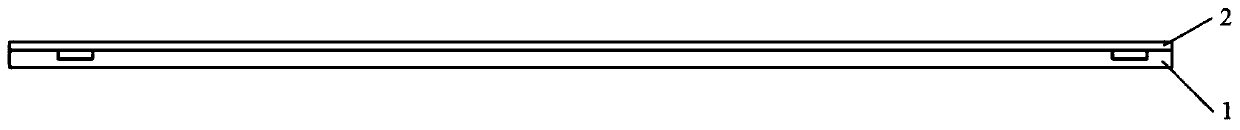

[0017] The structure diagram of the present invention is as figure 1 , figure 2 , image 3 As shown, it includes cold plate base plate 1, cold plate cover plate 2, runner inlet 3, main channel 4, longitudinal microchannel unit 5, return flow channel 6, runner outlet 7, upper channel 8, lower channel 9, single microchannel Channel flow channel 10, a group of inclined channels 11. The inner flow channel of the microchannel cold plate is processed on the cold plate substrate 1 by milling to process the flow channel inlet 3, the main channel 4, the longitudinal microchannel unit 5, the return flow channel 6, the flow channel outlet 7, the upper channel 8, and the lower channel 9 , a single micro-channel flow channel 10, alternate inclined channels 11 and other structures, the cooling liquid enters from the flow channel inlet 3, flows through each lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com