Oil fume exhaust device for kitchen

A technology for exhausting oil fume and kitchen, which is applied in the field of kitchen oil fume exhaust devices, which can solve the problems that oil fume easily diffuses into the kitchen space, affects human health, pollutes the environment, etc., and achieves the effects of being beneficial to human health, easy to clean, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

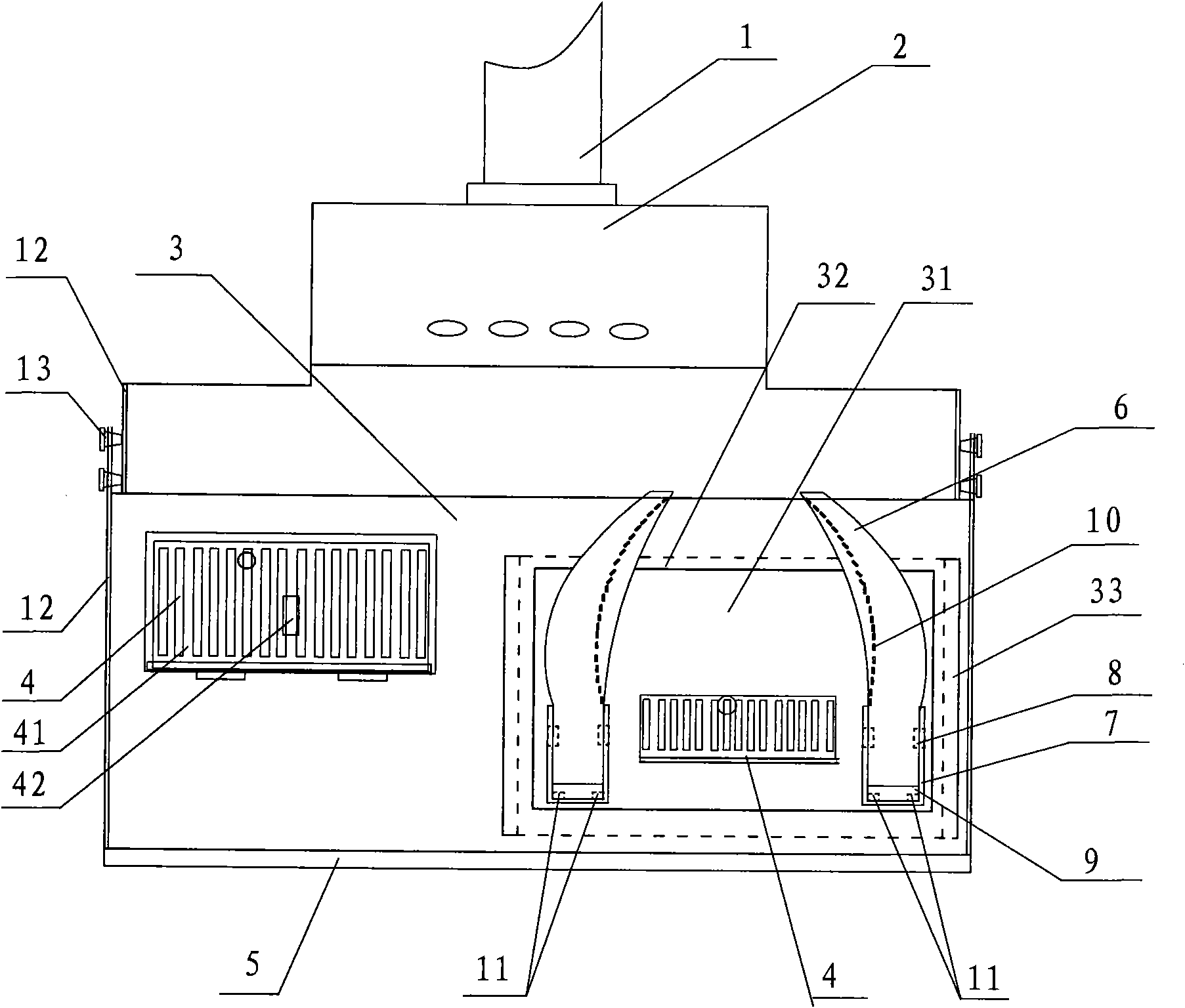

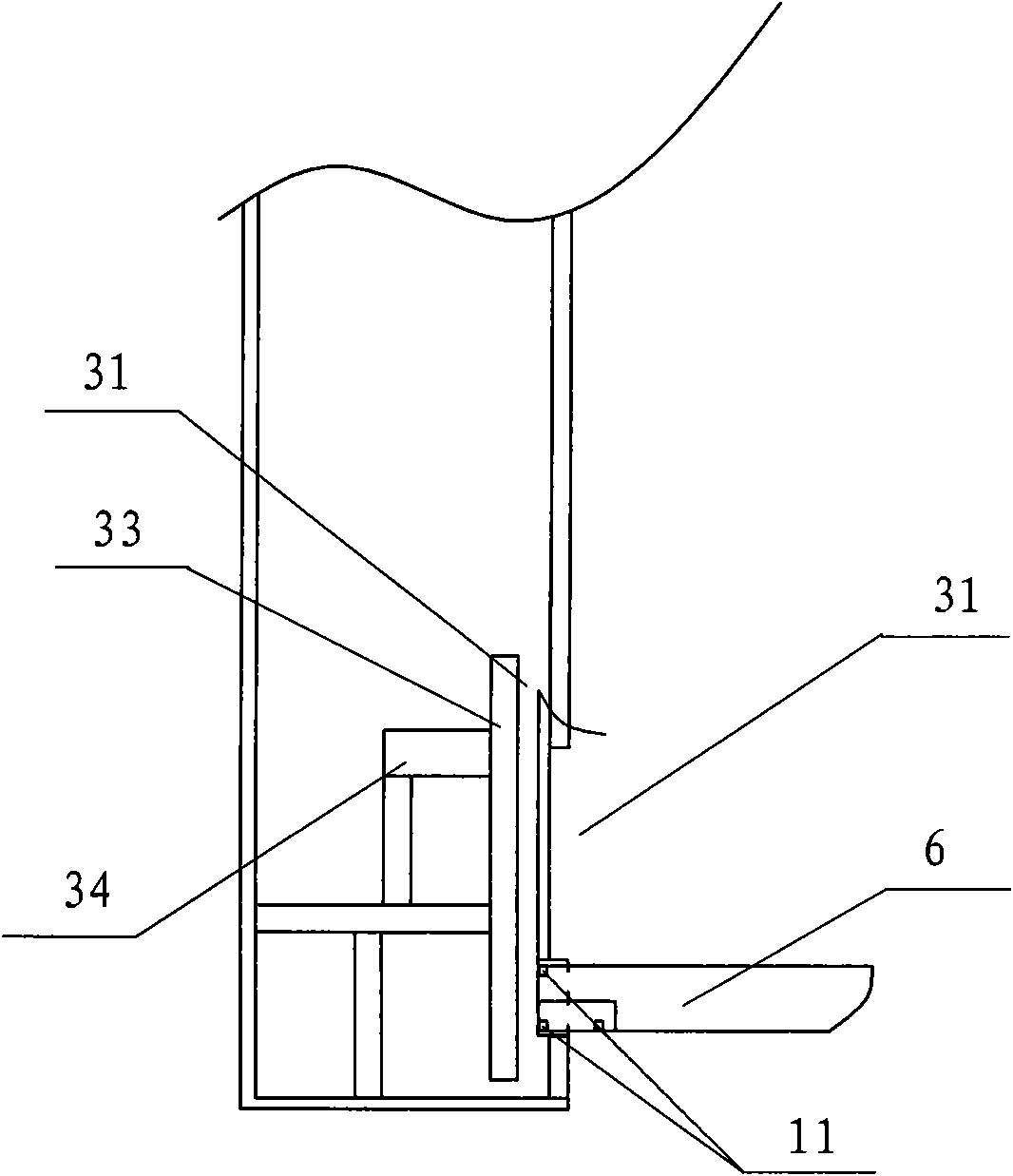

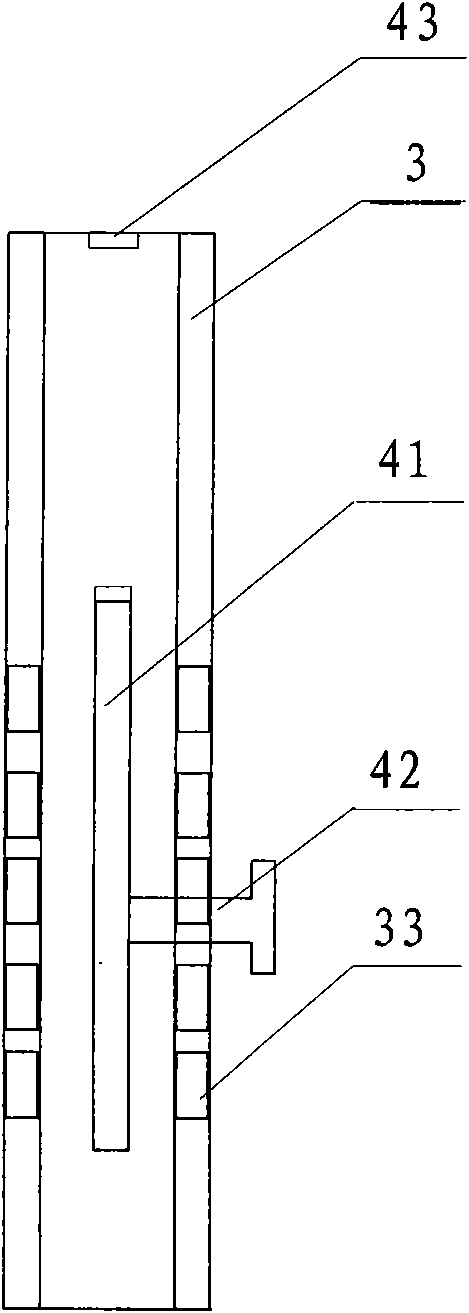

[0011] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

[0012] like Figure 1-Figure 3 As shown, the kitchen oil fume exhaust device includes an oil fume exhaust outlet 1, an exhaust motor 2, and a collection flue. A smoke inlet hole 30 is installed on the collection flue panel 3 and a detachable smoke inlet hole plate 4 is movably connected by a rotating card. A movable smoke baffle 41 is installed on the smoke inlet plate 4, a movable handle 42 is installed on the movable smoke baffle 41, and a suction block 43 is installed at one end of the smoke inlet 41, and the movable handle of the movable smoke baffle 41 When 42 moves upwards, the movable smoke baffle 41 is sucked by the suction block 43, and the smoke inlet 30 is opened. When the moving handle 42 of the movable smoke baffle 41 moves downward, the smoke inlet 30 is closed, and the flue gas is collected. The bottom end is equipped with a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com