Electric precipitator

An electrostatic precipitator and electrode technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems of increased manufacturing cost, commercial application, and dust collection ability cannot be improved, and achieve the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

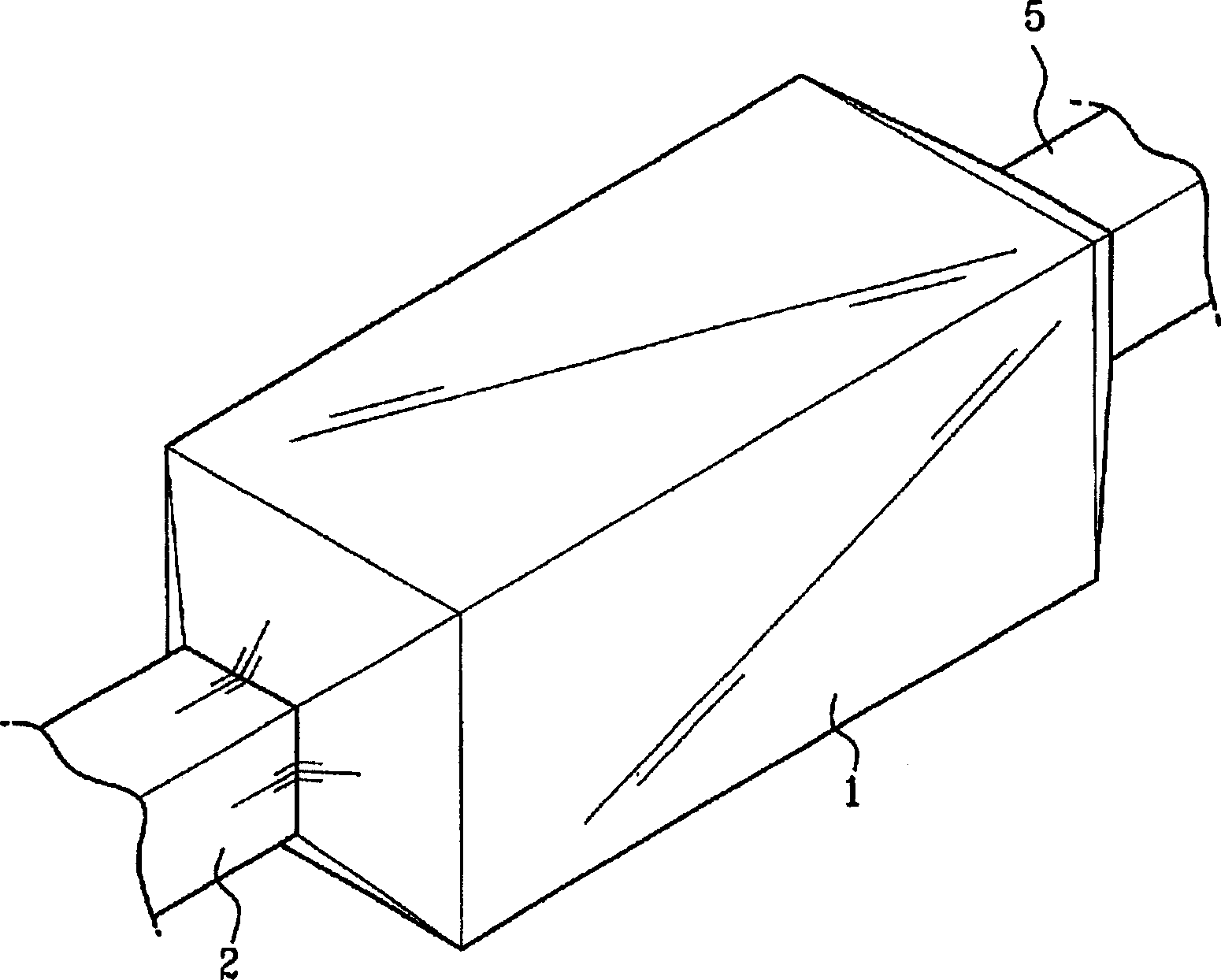

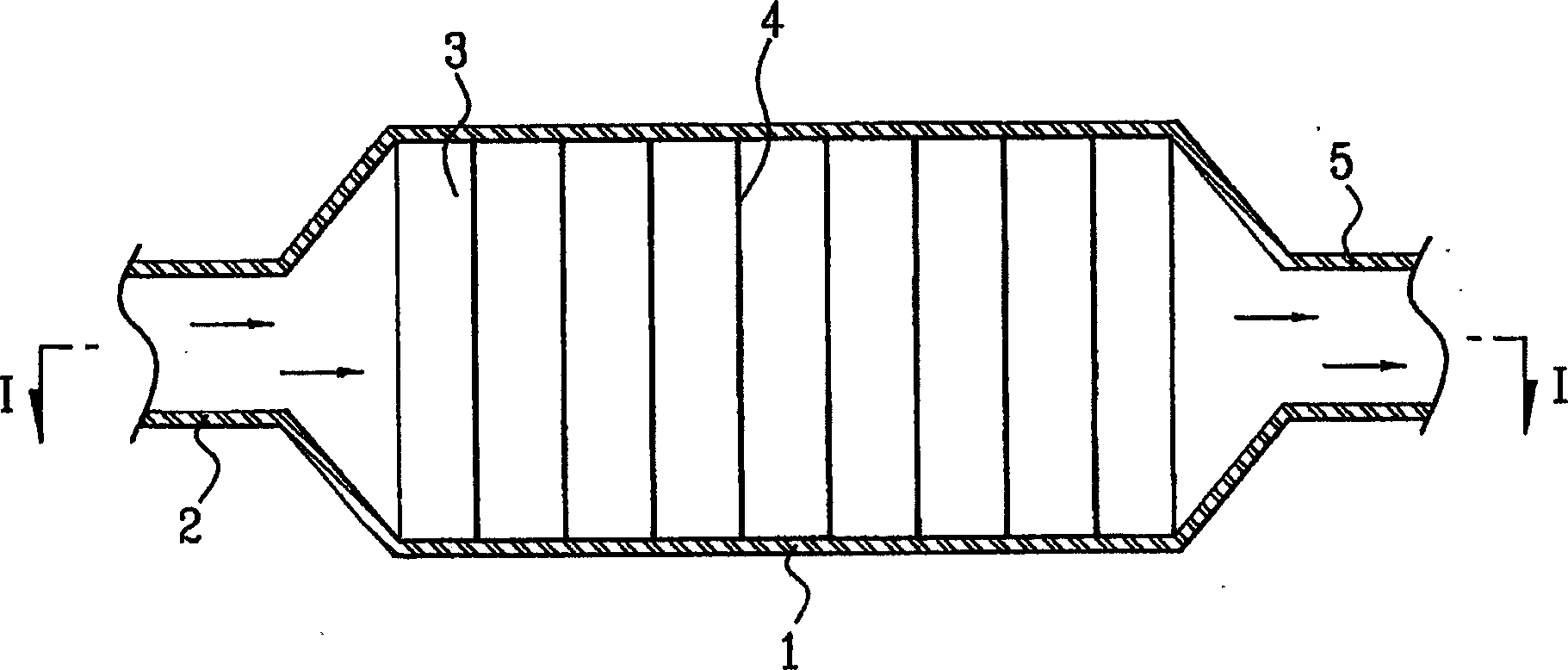

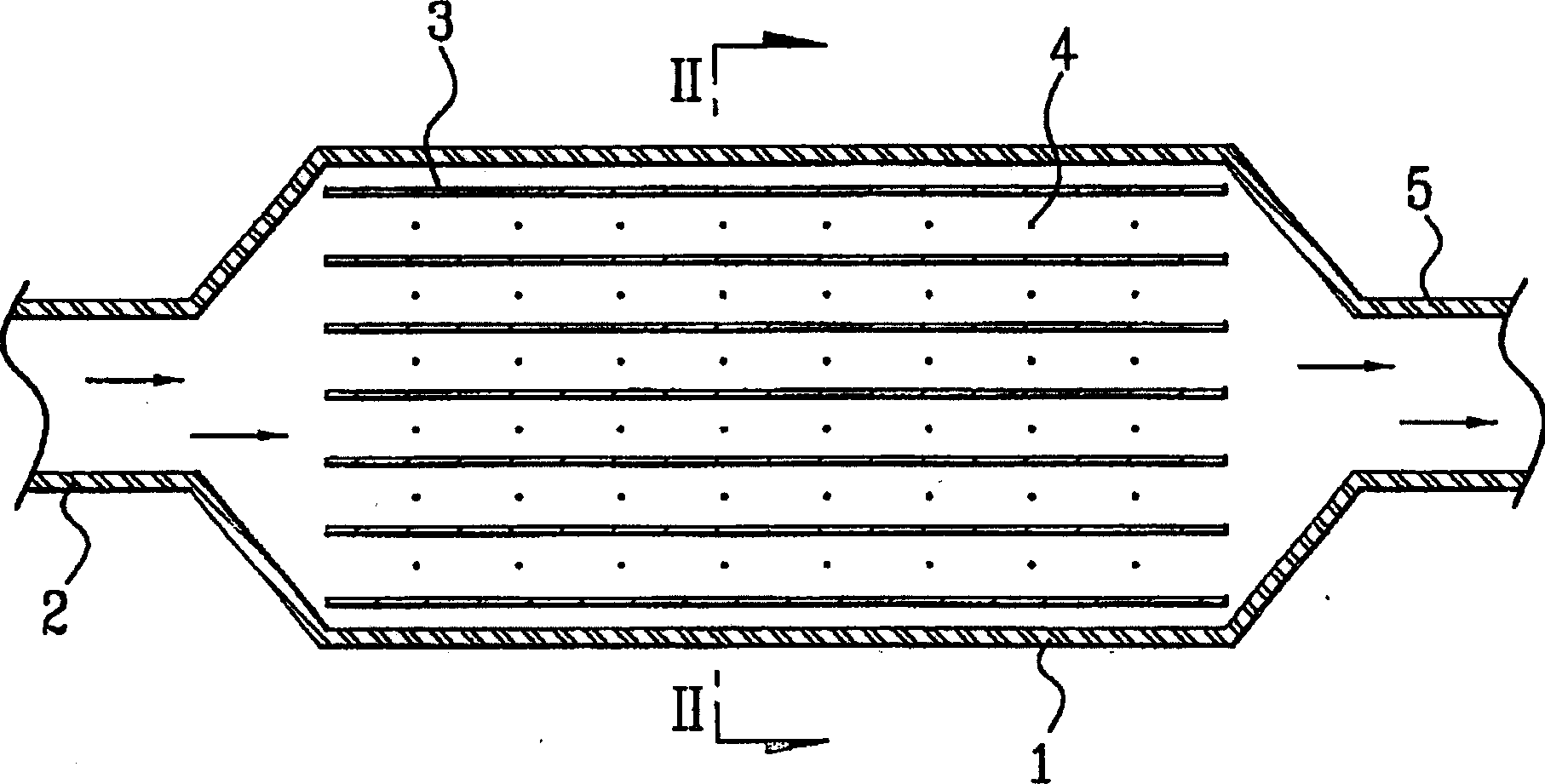

[0043] attached Figure 6 is a perspective view of an electrostatic precipitator according to the present invention, with Figure 7 is a vertical sectional view of the electrostatic precipitator according to the present invention, with Figure 8 is along Figure 7 Sectional view of midline III-III, Figure 9 is a perspective view showing the main construction of the electrostatic precipitator according to the present invention. As shown in the figure, the dust remover of the present invention includes: a housing 11, which forms an internal space and is divided into a plurality of subspaces in the vertical direction by a partition wall 12; an inlet 13, which is located outside the front side of the housing, For inhaling the air mixture containing dust; a plurality of inlet ducts 14, connected at one end to the bottom side of the inlet and at the other end to the front side of the enclosure 11, divide and guide the air mixture to each lower air intake of the subspace of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com