A matrix material suitable for constructed wetland, constructed wetland system and application

A constructed wetland system and wetland technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as low operating cost and insufficient dissolved oxygen, and achieve increased effective area, Inexpensive, enhanced oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039]In order to further improve the electrical conductivity of the carbon fiber felt, the present invention also provides a pretreatment method for the carbon fiber felt, that is, using concentrated hydrochloric acid for pretreatment; specific implementation methods are as follows:

[0040] The carbon fiber felt is soaked in 8-12% concentrated hydrochloric acid and boiled for 25-35 minutes.

[0041] The second aspect of the present invention provides a constructed wetland system, characterized in that the constructed wetland system includes the matrix material described in the first aspect;

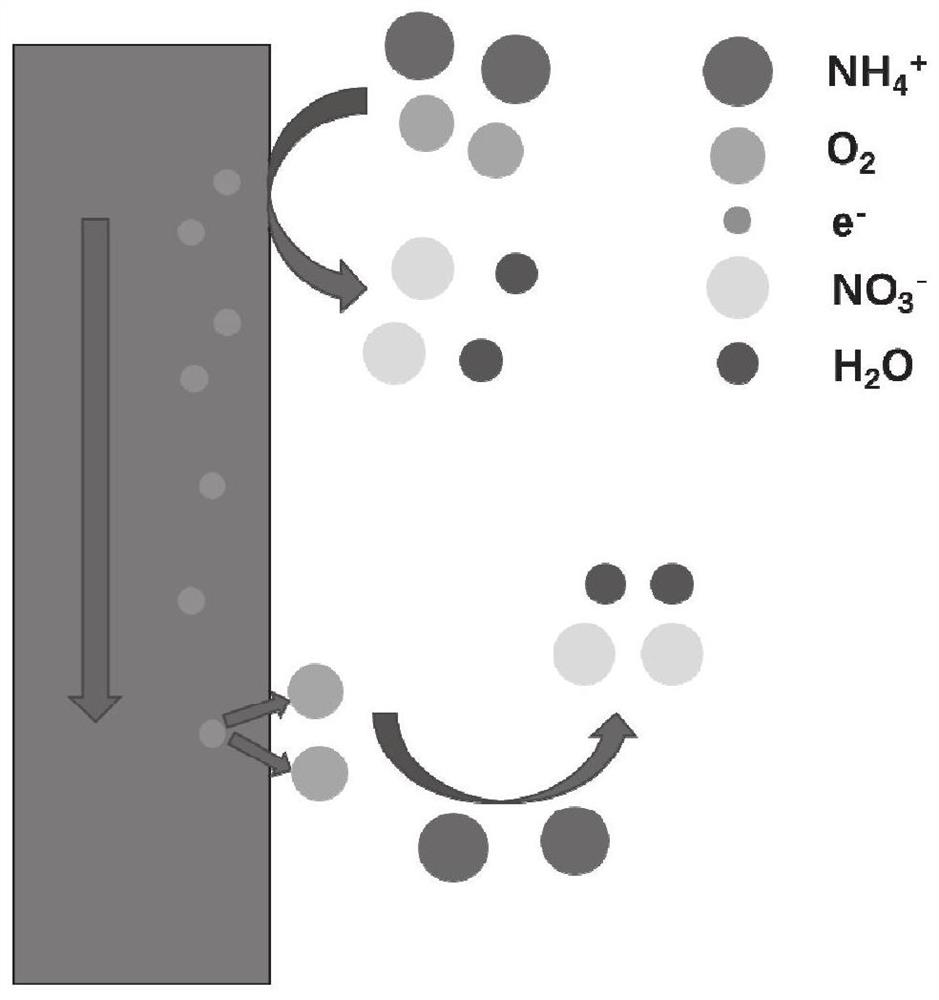

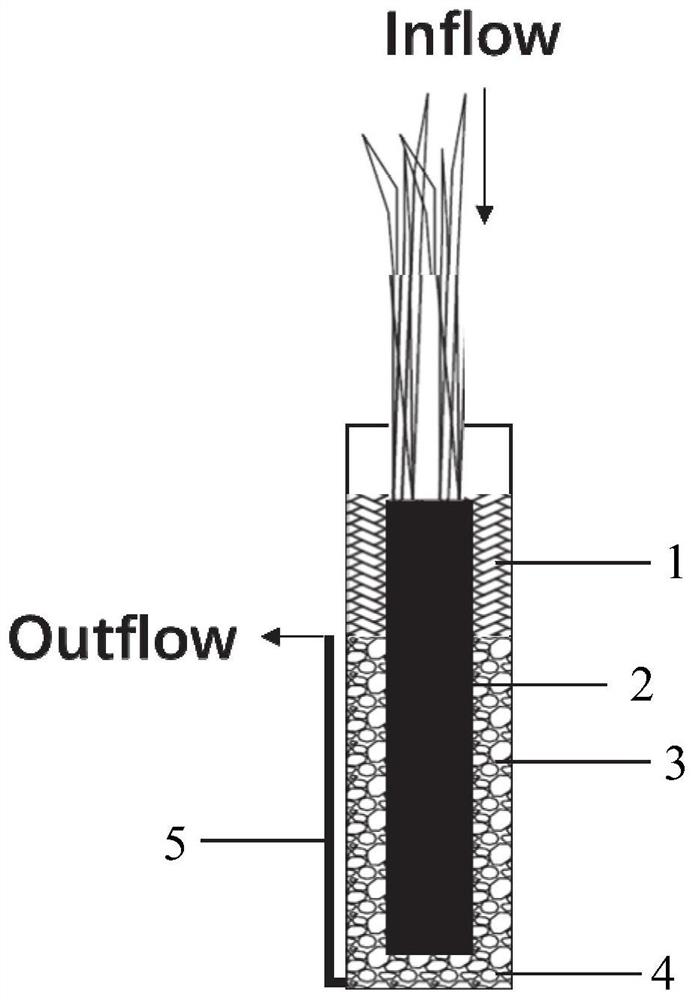

[0042] The constructed wetland system includes a main body and a drainage device. The main body part is an unsaturated area and a saturated area from top to bottom, the adsorption material is arranged in the unsaturated area, and the conductive material runs through the upper part of the unsaturated area and the saturated area. .

[0043] Preferably, aquatic plants are also planted on ...

Embodiment 1

[0064] In this embodiment, a constructed wetland system is provided. The constructed wetland system has a cylindrical outer wall made of PVC material with a diameter of 25 cm and a height of 80 cm. 10cm thick gravel (diameter 2-3cm) is laid on the lower part of the device as the support layer 4 . Vertically arrange the carbon felt cylinder 2 with a diameter of 20cm and a height of 70cm, the middle part is filled with a quartz sand layer 3 with a height of 60cm, the upper 10cm is filled with woven superfine fibers with a length of 200cm and quartz sand 1 with a diameter of 2-4mm, and a water outlet is set at the bottom of the device , and connect the soft water outlet pipe 5 to raise the water level, and control the height of the unsaturated zone to be 10cm. A perforated PVC pipe with a diameter of 5 cm was vertically inserted in the middle of each device to measure physical and chemical indicators such as dissolved oxygen (DO), oxidation-reduction potential (ORP), temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com