Optical pumping vertical external cavity emitting laser with gradient band gap barrier absorption layer

A technology for emitting lasers and gradient bandgap, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of poor beam quality of edge-emitting semiconductor lasers, large volume of solid-state lasers, and difficulty in high-power laser output. Effects of quantum efficiency, superior collection capability, and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

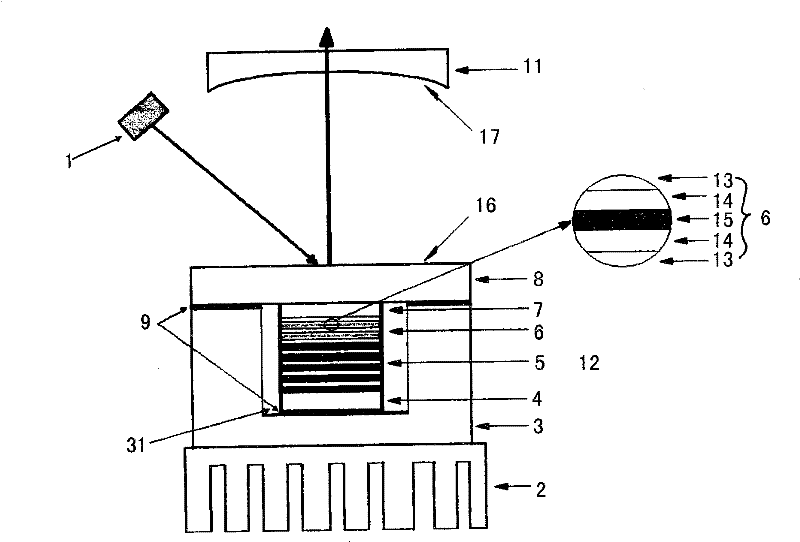

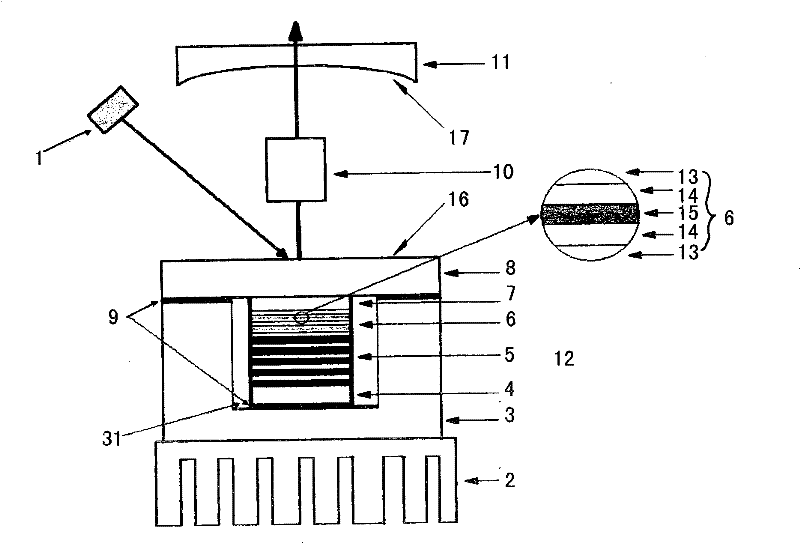

[0058] see figure 1 As shown, a first embodiment of an optically pumped vertical external cavity surface emitting laser with a gradient bandgap barrier absorbing layer in the present invention includes:

[0059] A copper heat sink 3, a groove 31 is opened on the copper heat sink 3;

[0060] A transparent heat sink 8, the transparent heat sink 8 adopts diamond or SiC or sapphire, and the upper surface of the transparent heat sink 8 is evaporated with an anti-reflection film 16;

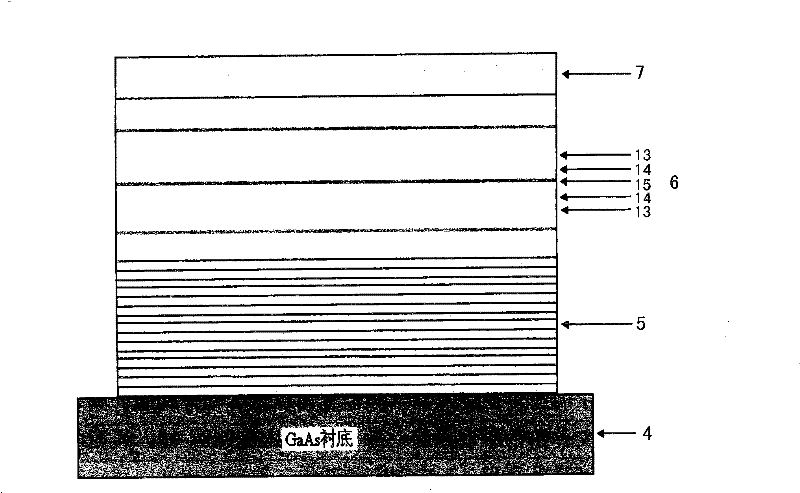

[0061] An epitaxial wafer 12, the epitaxial wafer 12 is connected to the lower surface of the transparent heat sink 8 by means of liquid adsorption, after the connection, the transparent heat sink 8 and the epitaxial wafer 12 are fixedly connected to the copper heat sink 3 through solder 9, so that the epitaxial wafer 12 Accommodated in the groove 31; the epitaxial wafer 12 includes: a substrate 4; a multilayer Bragg reflector 5, which is fabricated on the substrate 4, and the multilayer Bragg reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com