Method for manufacturing ohmic contact on SiC matrix for preventing transverse spreading of metal

An ohmic contact and substrate technology, applied in semiconductor devices and other directions, can solve the problems of deviation from design requirements, increase parasitic parameters, and reduce the performance of SiC devices or circuits, and achieve the effect of improving performance and reducing parasitic parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

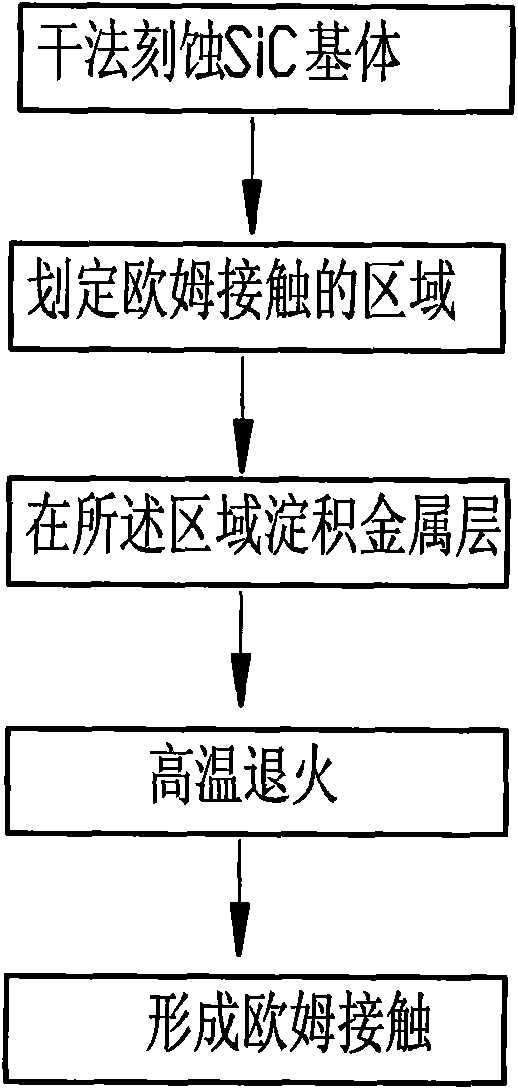

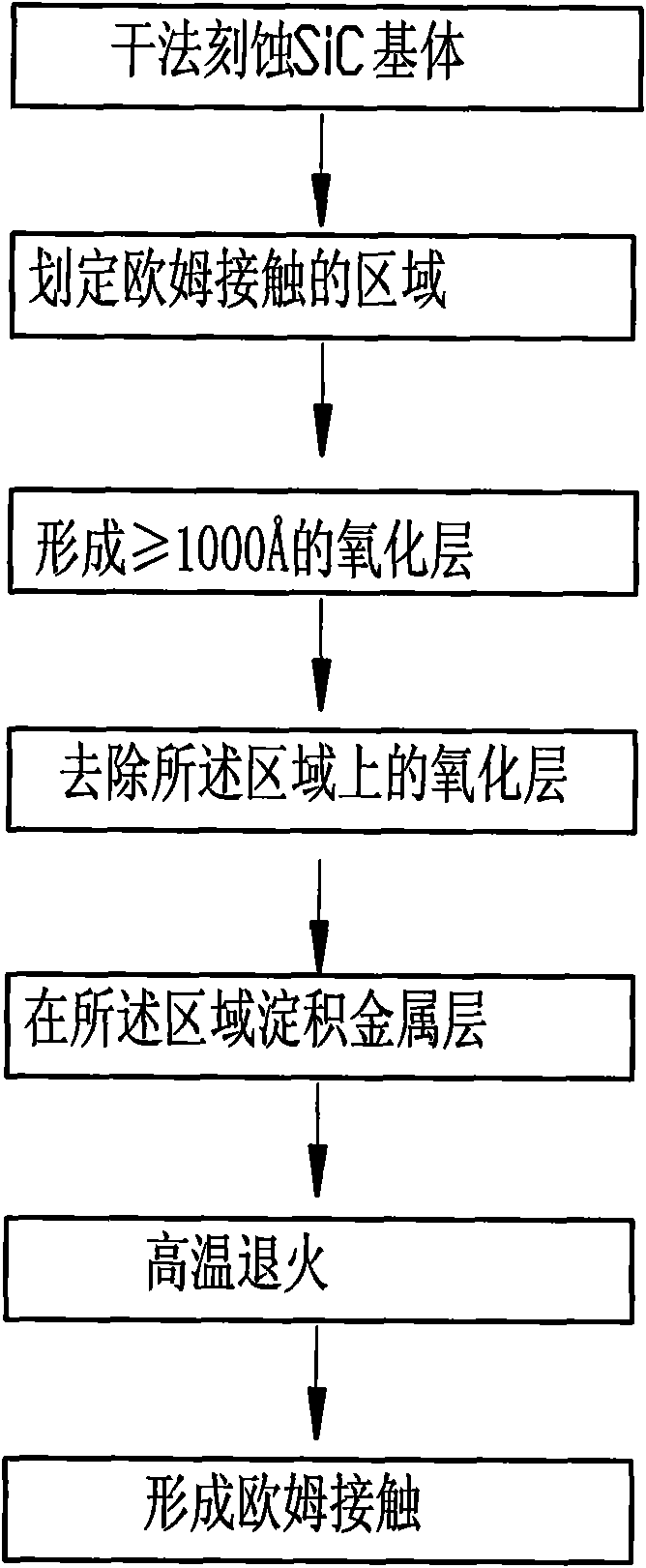

[0020] The process flow of the present invention is as figure 2 Shown. The method for manufacturing an ohmic contact of the present invention is described below by taking an example of manufacturing an ohmic contact of a field effect transistor:

[0021] 1) Use dry etching method to etch the required SiC matrix 1, see image 3 .

[0022] 2) The groove 5 is etched by dry etching on the upper surface of the SiC substrate 1. The groove 5 is used to make Schottky contacts, see Figure 4 ; Delimit the area of ohmic contact outside the groove on the SiC substrate. The dry etching is performed according to the existing process.

[0023] 3) Oxidation step: oxidize the upper surface of the SiC substrate and its adjacent sidewalls to form a thickness of 1000~ Oxide layer 2, see Figure 5 . The composition of the oxide layer is SiO 2 .

[0024] The conditions of the oxidation step are:

[0025] Oxidation temperature: 1200~1350℃;

[0026] Oxidation rate: ≥ / hour;

[0027] Oxidizing atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com