Blending and mixing groove

A mixing and tank technology, applied in mixers, mixers with rotary stirring devices, dissolution, etc., can solve the problems of high alkali concentration and affecting alumina production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

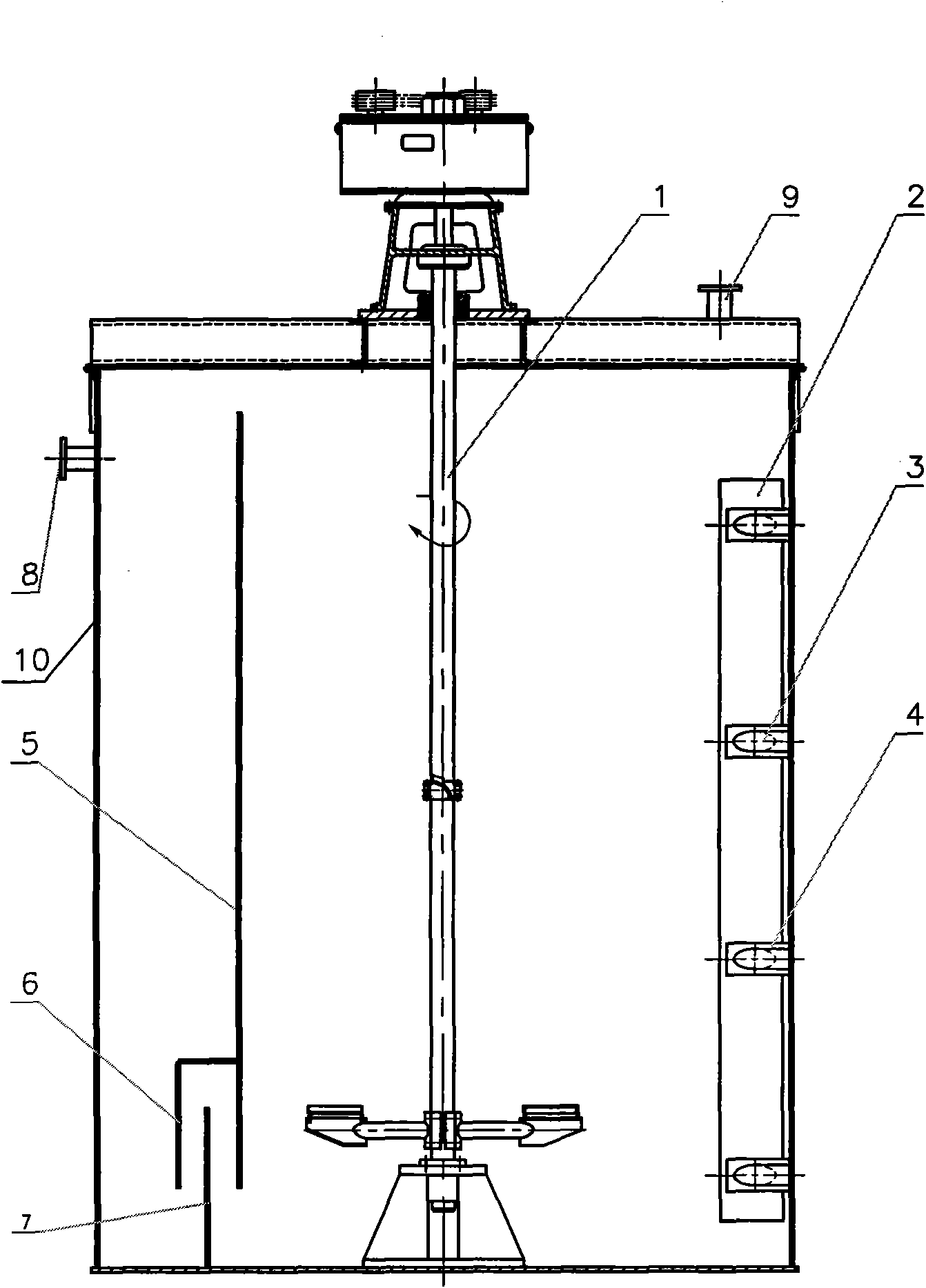

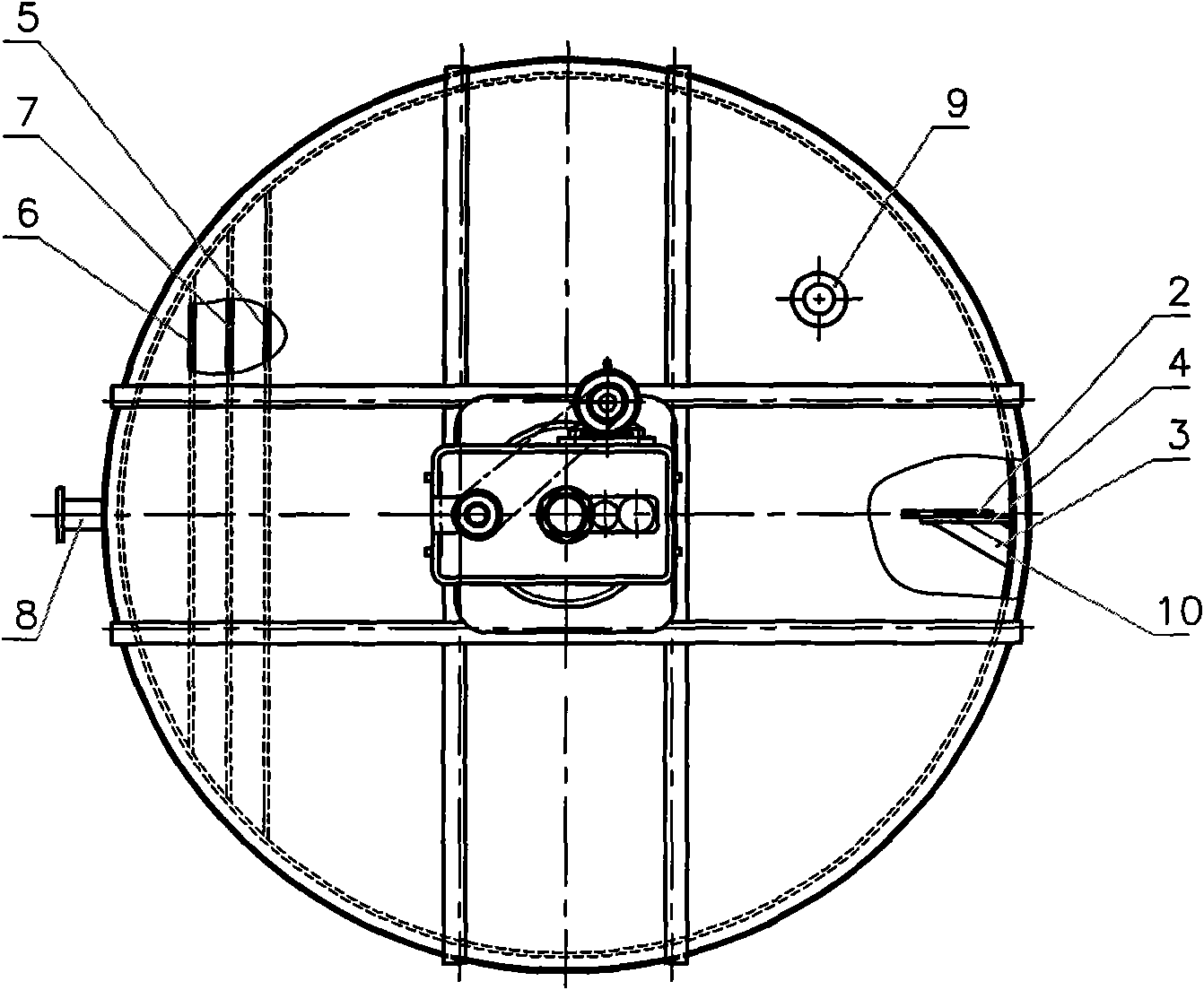

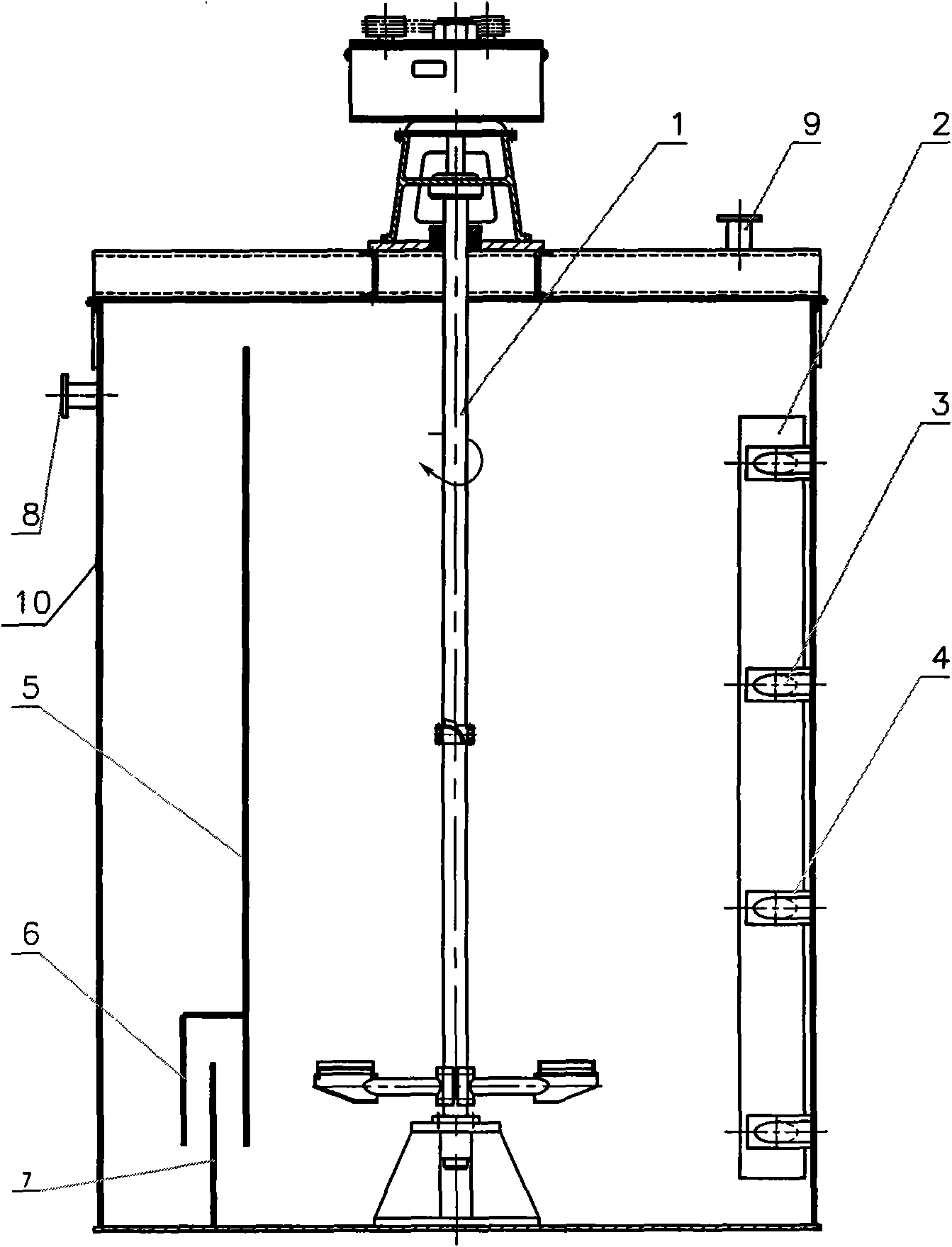

[0020] Such as figure 1 with figure 2 Shown, a kind of deployment mixing tank of the present invention, it comprises tank body 10, is provided with stirring shaft 1 in the middle part of tank body 10, is provided with liquid outlet 8 and feed inlet 9 on tank body 10, in tank body 10 is provided with a liquid blocking plate 5, and an inverted baffle groove 6 is provided at the bottom of the liquid blocking plate 5. One end of the baffle plate 7 is inserted into the baffle groove 6, and the other end of the baffle plate 7 is connected to the bottom of the tank body 10. The inner wall is fixed, the two sides of the baffle plate 7 are fixed to the side inner wall of the tank body 10, the two sides of the liquid blocking plate 5 and the baffle groove 6 are fixed to the side inner wall of the tank body 10, the liquid blocking plate 5 and the baffle groove 6 are fixed One surface is fixed; the liquid outlet 8 is arranged on the upper part of the side wall of the tank body 10, and t...

Embodiment 2

[0023] The feed inlet 9 in Embodiment 1 is arranged on the side wall of the tank body. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com