Device for preparing thin film by liquid level drawdown method

A thin film and liquid surface technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uncontrollable coating environment, uneven coating, complex and expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

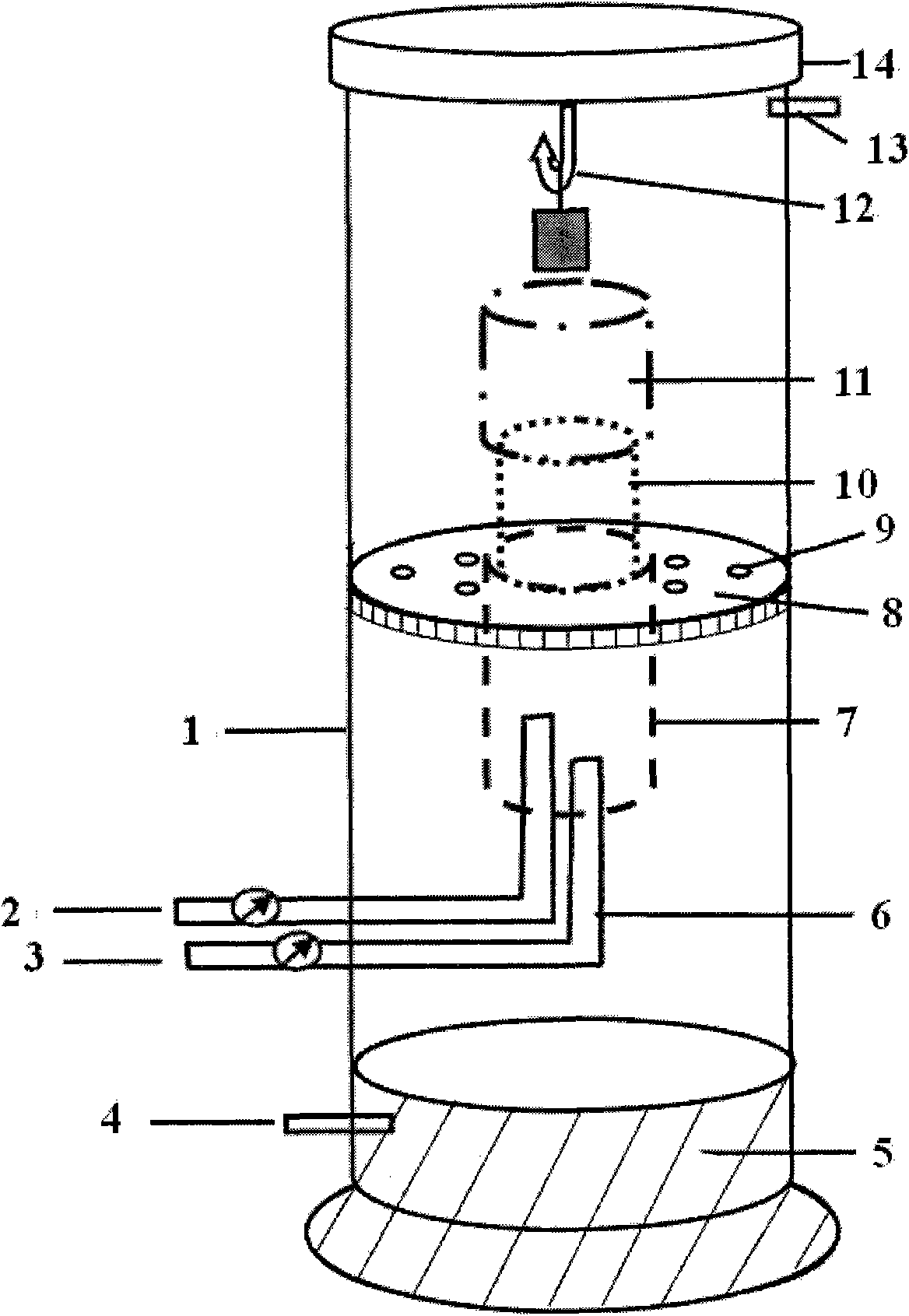

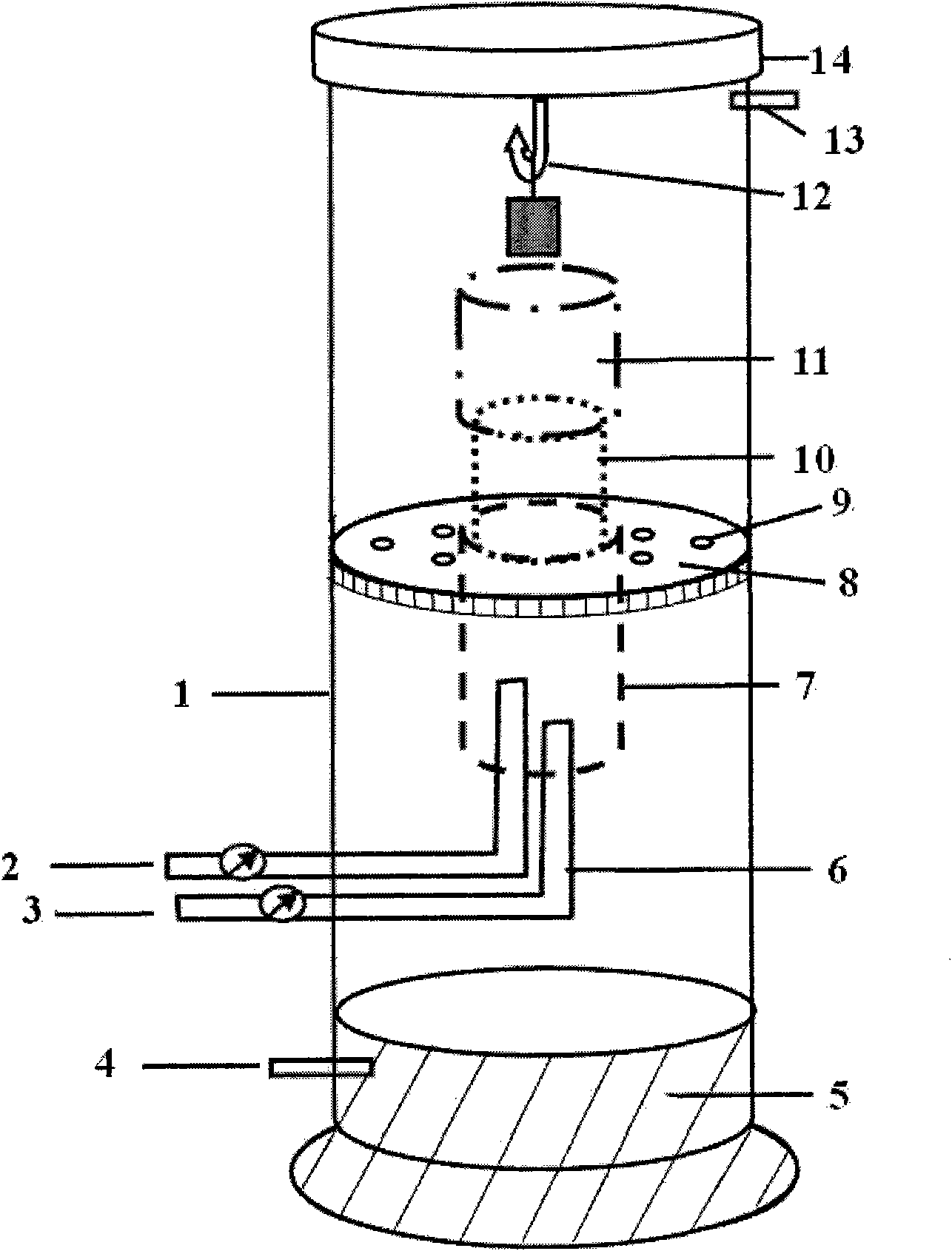

[0023] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further: figure 1 Shown, a kind of device that the liquid level drops method prepares thin film, this device comprises:

[0024] A transparent outer cover 1 is a cylinder with a movable upper cover 14 on the top for fixing the substrate support 12 and sealing and dustproof;

[0025] A substrate support 12, which can be a hook-shaped body, is fixed at the center of the upper cover 14;

[0026] A partition 8, located in the middle of the cylindrical transparent cover 1, separates the transparent cover into upper and lower spaces; the partition 8 is provided with a plurality of air holes 9, and the center of the partition is provided with a hole of the same size as the piston sleeve; The above-mentioned multiple air holes 9 are evenly distributed on the surface of the partition, and are used for gas circulation between the upper and lower parts of the transparent outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com