Underwater epoxy resin coating and preparation method thereof

A technology of epoxy resin coating and liquid epoxy resin, which is applied in the field of underwater epoxy resin coating and its preparation, can solve the problems of poor wet surface adhesion, etc., and achieve good protection, good leveling, and coating film. Smooth and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with embodiment.

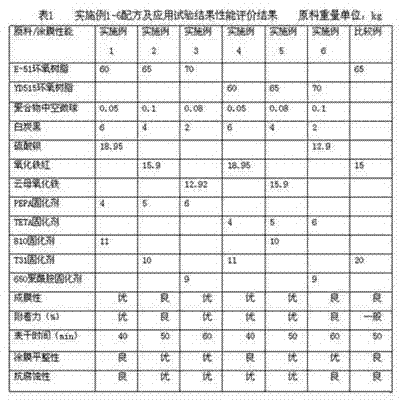

[0034] The formulations of Examples 1-6 are shown in Table 1, rows 1-12.

[0035] Preparation:

[0036] Preparation of component A: After mixing the pigment and filler with liquid epoxy resin, use a three-roller to grind until the particle size of the pigment and filler particles is ≤30 microns, then add white carbon black, stir evenly, add polymer hollow microspheres, and then Stir well, filter and pack.

[0037] Preparation of group B: Weigh the two types of curing agents, hydrophilic and lipophilic, according to the predetermined mass ratio, mix, stir evenly, and pack.

[0038]Application test: Weigh 1kg of prepared component A and 0.15kg of component B, mix well, and apply on the underwater metal and concrete structures. Both have good film-forming properties (visual inspection) and adhesion (the test paint is coated on the rust-removed steel plate, and it is evaluated by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com