Repairing and reinforcing process of construction cracking member

A technology of buildings and components, which is applied in the direction of building construction, building maintenance, construction, etc., to achieve the effect of light weight, good toughness and easy construction of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

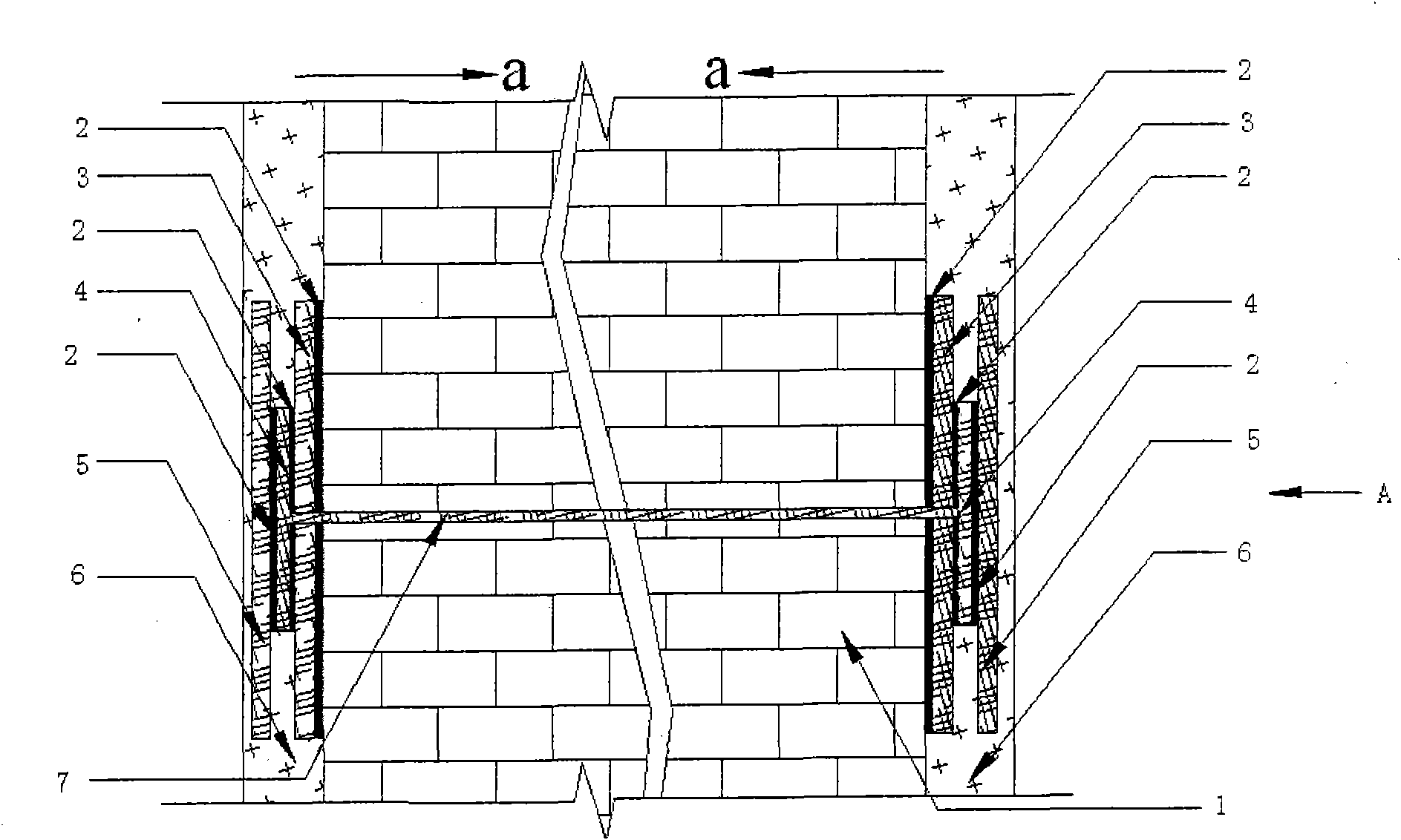

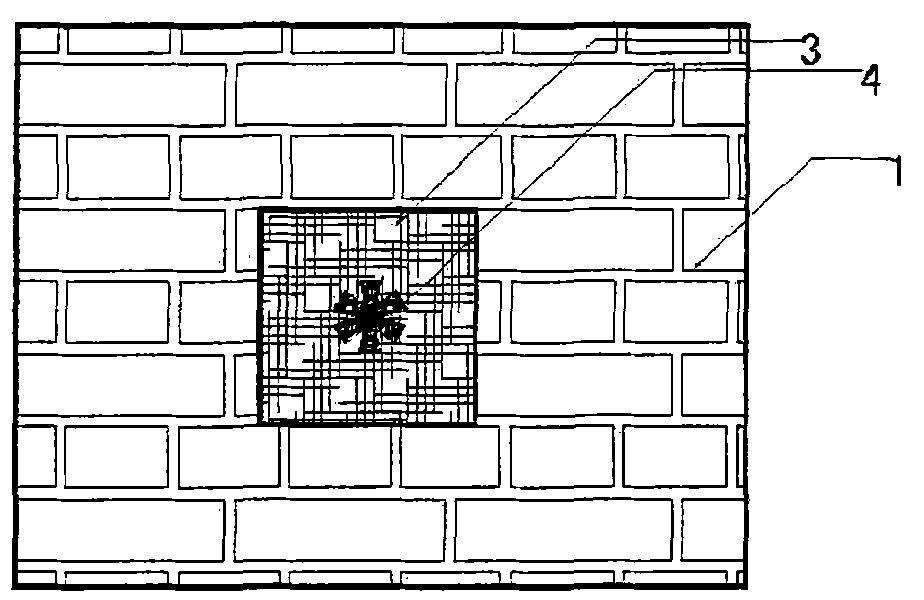

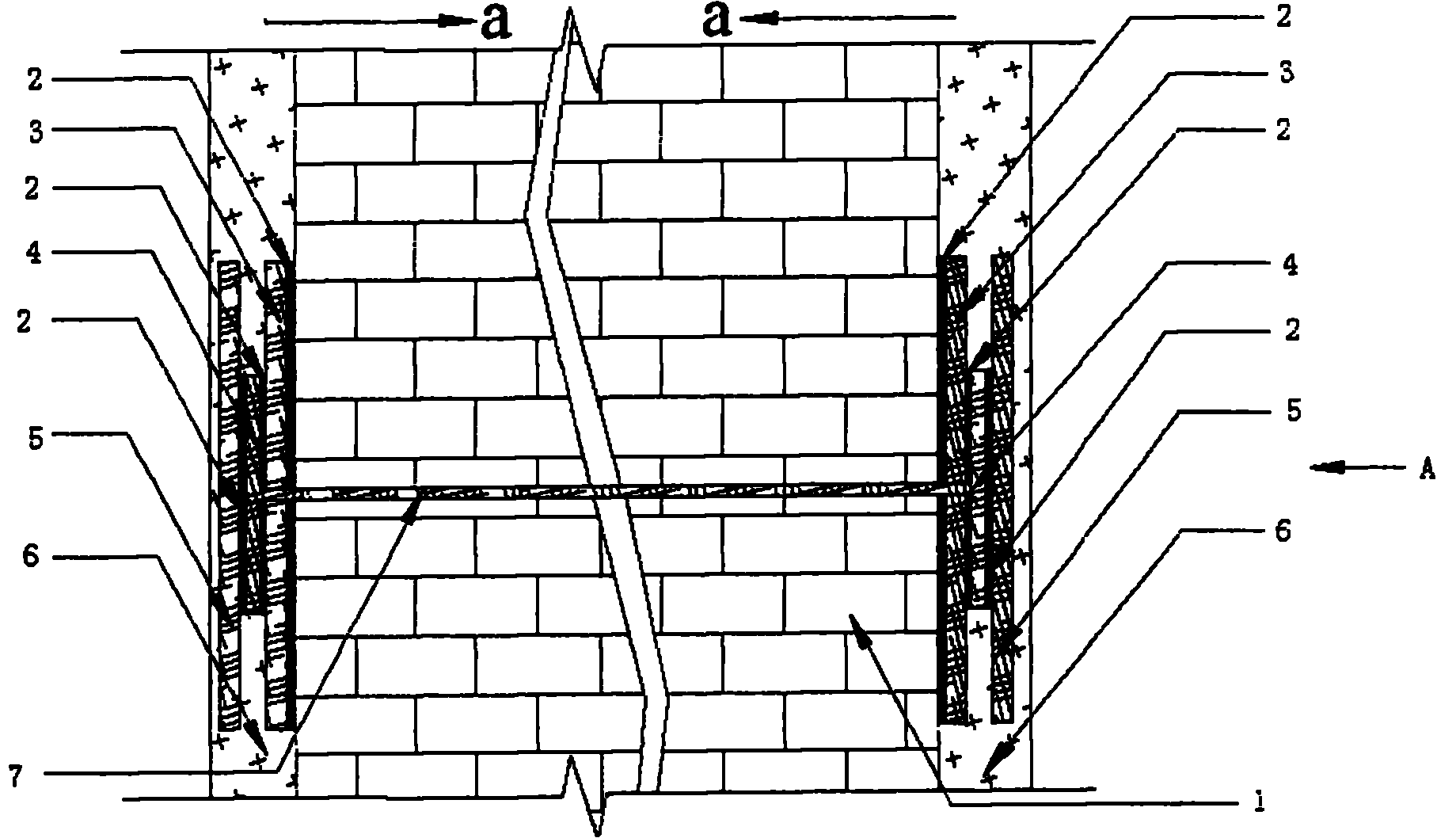

[0024] The present invention is further described below in conjunction with accompanying drawing:

[0025] combined with figure 1 , figure 2 , a repair and reinforcement process for cracked member 1 (cracked brick column), is characterized in that the process comprises the steps:

[0026] 1) Detect the geometric dimensions, cracks and crack distribution of the cracked member 1 clearly, and prepare an appropriate amount of fiber cloth, roll part of the fiber cloth into a fiber cloth drum to form the fiber cloth anchor rod 7, and cut part of the fiber cloth into small pieces to form the fiber cloth Reinforcement layer 5, in addition, cut out holes in the fiber cloth partially cut into small pieces to form fiber cloth anchor 3;

[0027] 2), design and determine the crack and the corresponding reinforcement points on both sides of the crack on the cracked member 1;

[0028] 3) Using external facilities to apply external force a on both sides of the cracked member 1, forcefully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com