Non-lighting inspection apparatus

An inspection device and non-lighting technology, applied in measuring devices, nonlinear optics, material analysis through optical means, etc., can solve problems such as light leakage, image scatter, and blur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

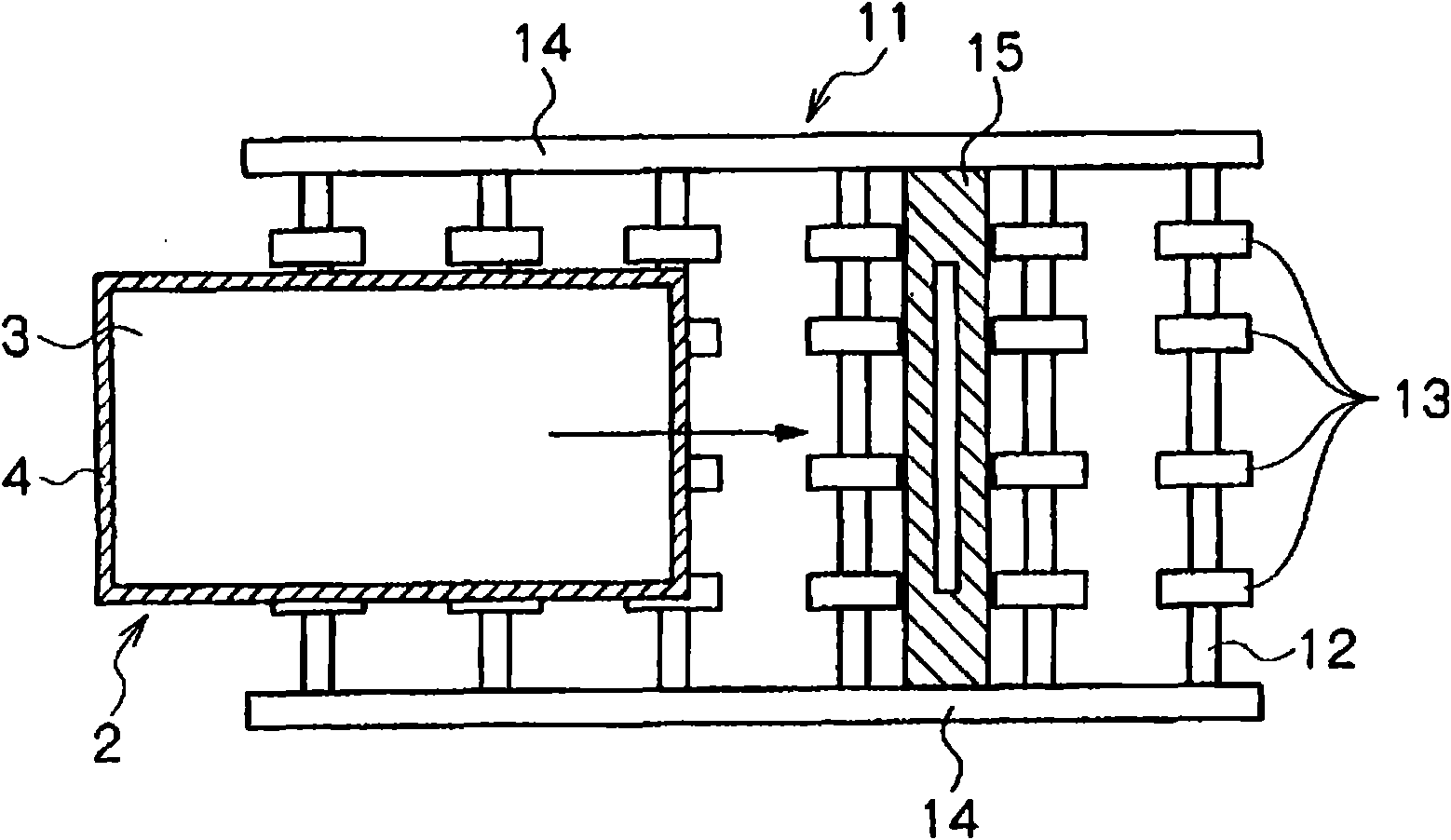

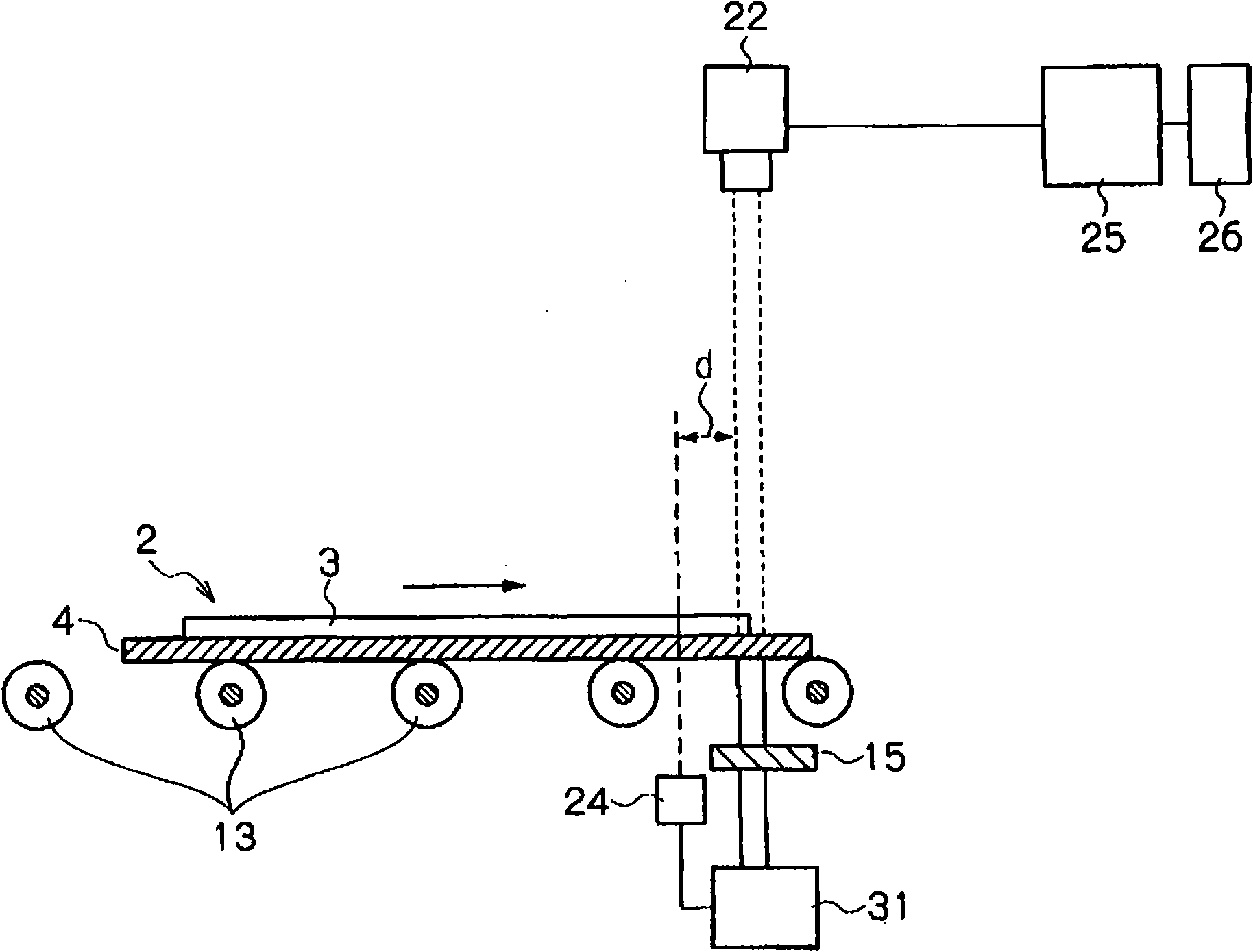

[0021] The non-lighting inspection device of this embodiment is assembled on a conveying device for conveying panels to be inspected. The conveying device is a general device installed on the production line of the panel to be inspected. figure 1 An example of this conveying device is shown. figure 1 The conveying device 11 in is a device that conveys the panel 2 to be inspected using a conveyer roller 13 supported by a drive shaft 12. The conveying device 11 connects a plurality of processing devices provided on the production line of the panel to be inspected, etc., respectively.

[0022] In the conveying device 11, a plurality of drive shafts 12 arranged at constant intervals are attached between the two side wall portions 14, respectively. A plurality of conveying rollers 13 are attached to each drive shaft 12. The drive shaft 12 is connected to a belt or the like not shown, and power is applied, so that the conveying roller 13 can be rotated. By respectively driving and ro...

no. 2 Embodiment approach

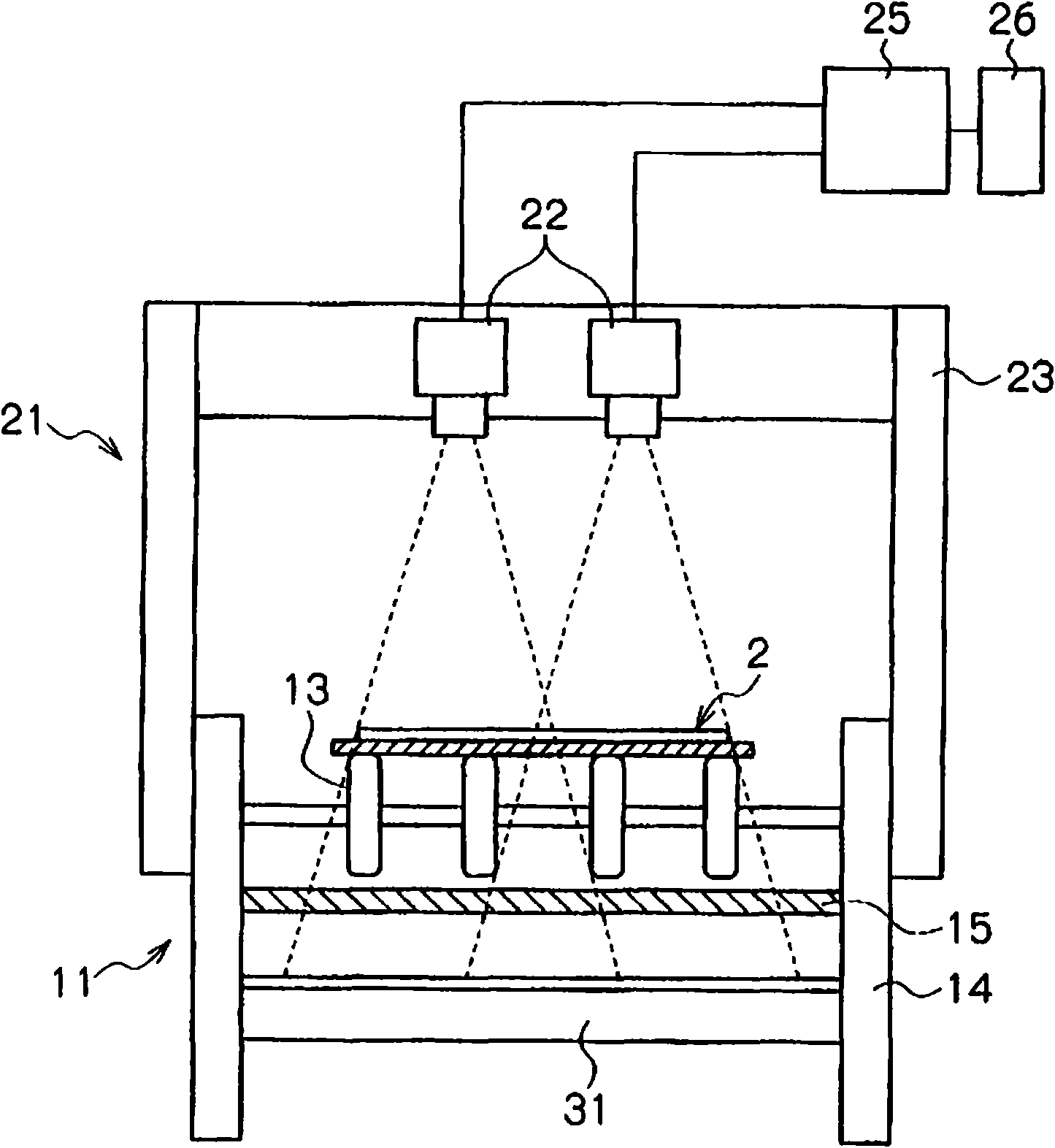

[0043] Next, the second embodiment of the present invention will be described. The overall configuration of the non-lighting inspection device of this embodiment is the same as the non-lighting inspection device of the first embodiment described above, and therefore the same reference numerals are given to the same members, and the description thereof is omitted.

[0044] The device of this embodiment can also be applied to the case where the panel size of the panel 2 to be inspected is changed. When the panel size of the panel 2 to be inspected is changed under the condition that the light irradiation range of the backlight 31 is constant, the light emitted from the backlight 31 either overflows from the panel 2 to be inspected or cannot illuminate the entire panel 2 to be inspected. In order to solve this problem, the shading plate 15' is used. The shading plate 15' is a light control plate that controls the light emitted from the backlight 31 so that the light enters the line...

no. 3 Embodiment approach

[0050] Next, a third embodiment of the present invention will be explained. The overall configuration of the non-lighting inspection device of this embodiment is the same as the non-lighting inspection device of the above-described first embodiment, and therefore the same reference numerals are given to the same members, and the description thereof is omitted. The non-lighting inspection apparatus of this embodiment has a polarizing plate.

[0051] Figure 7 This shows an example of performing non-lighting inspection on the panel 2'to be inspected without the polarizer 4. When inspecting the panel 2'to be inspected without the polarizer 4, all the light emitted from the backlight passes through the panel 2'to be inspected, so that the panel to be inspected cannot be judged because the high-brightness light enters the line scan camera 22 2'Is it a qualified product or a defective product. Therefore, the light control board 4'is provided in this embodiment. The light control pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com