Mobile lighting mechanism

A mobile, contact mechanism technology, used in instruments, nonlinear optics, optics, etc., can solve problems such as time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to describe in detail the structure and features of the present invention, the following is a preferred embodiment and is illustrated in conjunction with the drawings, in which:

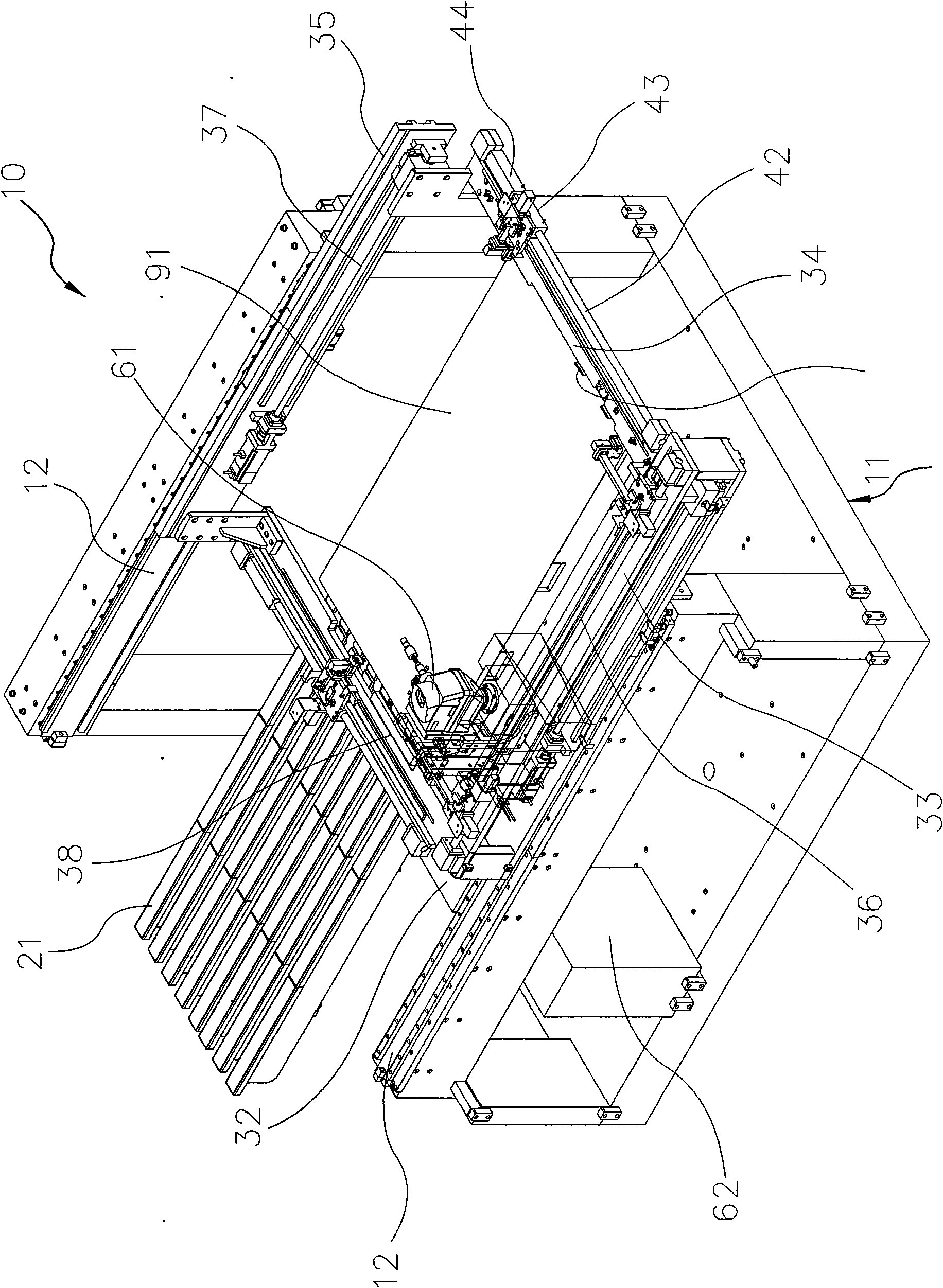

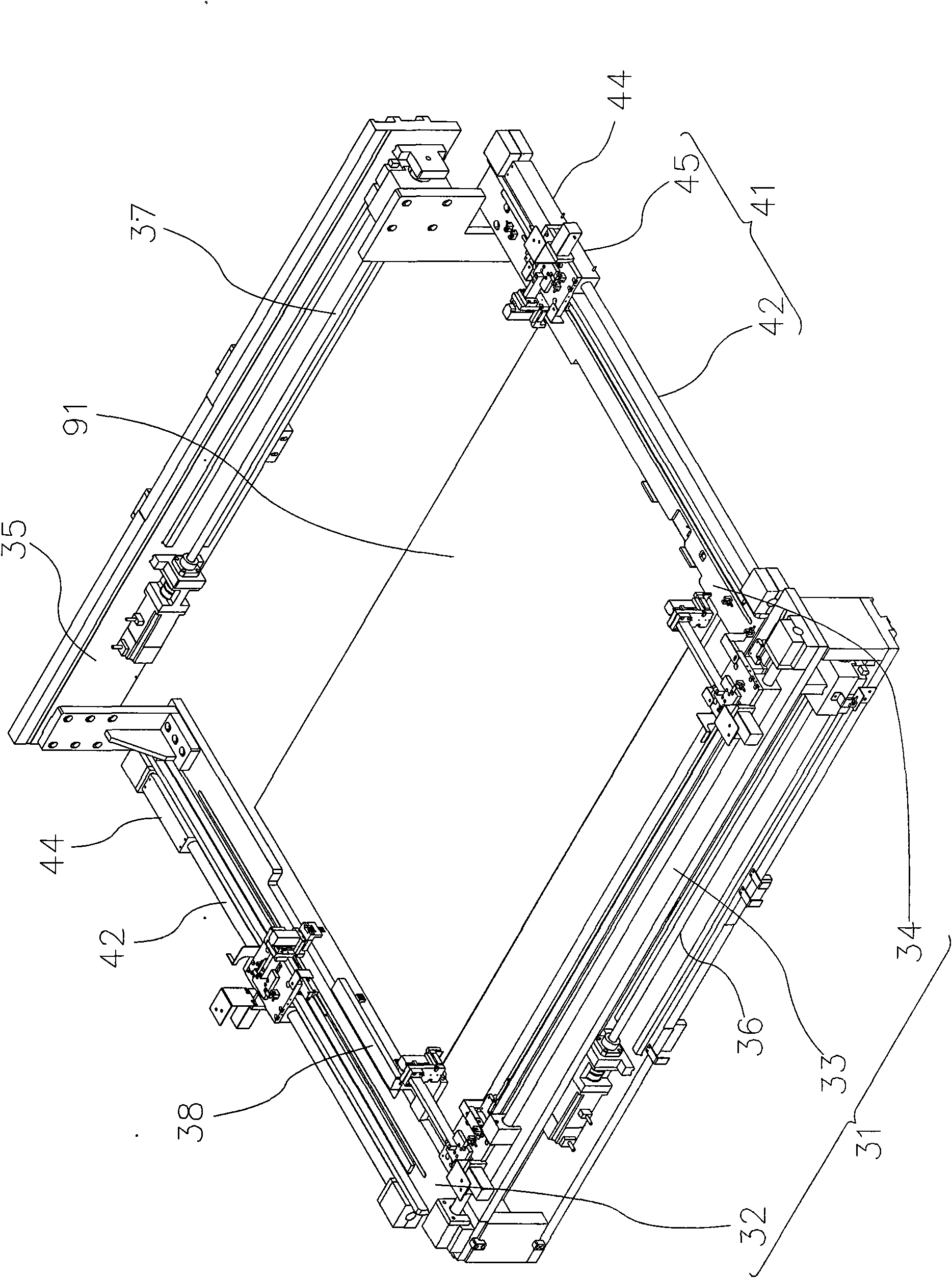

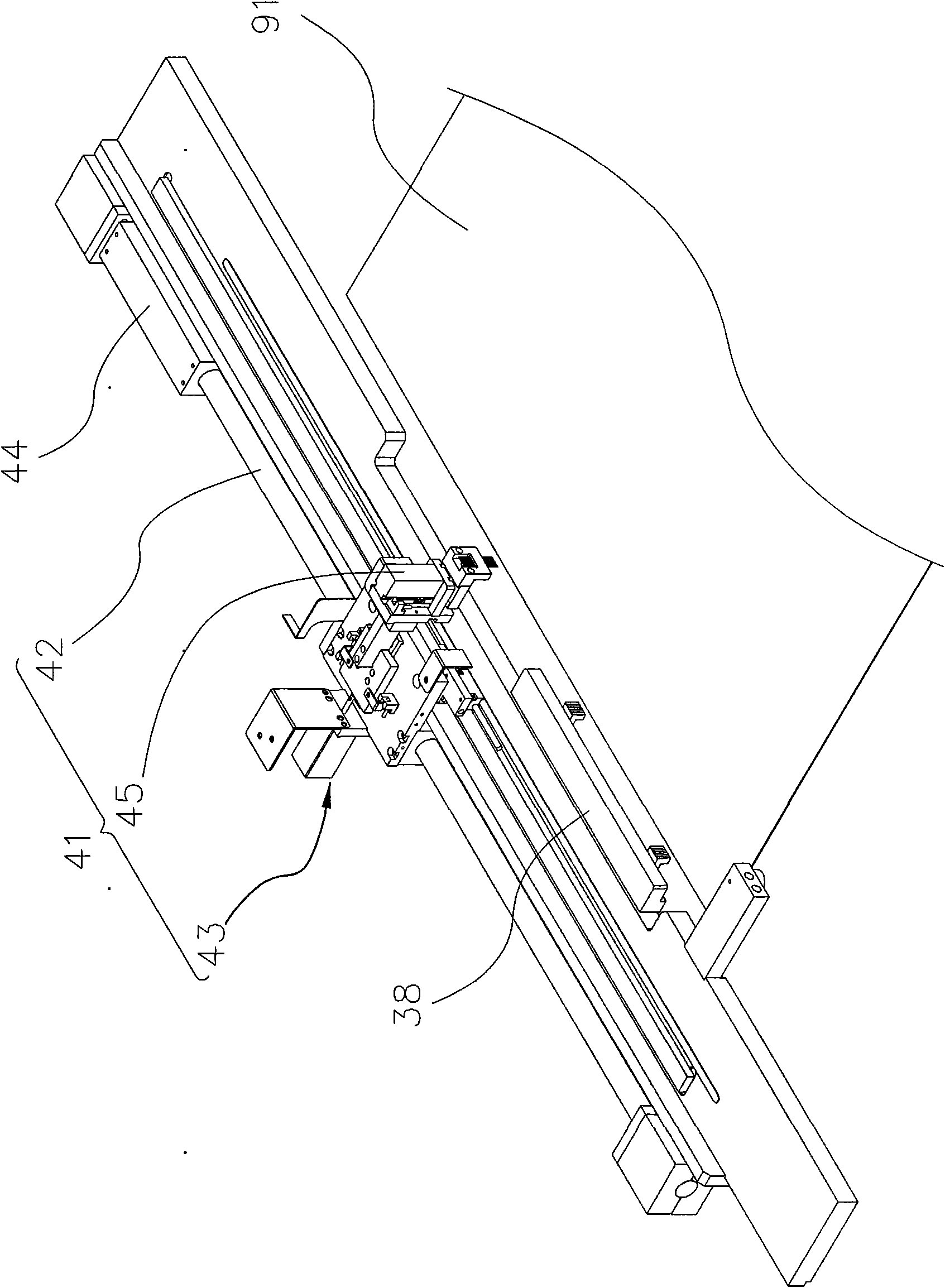

[0012] Such as Figure 1 to Figure 4 As shown, a mobile lighting mechanism 10 provided by the first preferred embodiment of the present invention includes: a machine table 11, a bearing table 21, a U-shaped frame 31, and a light test mechanism 41; The platform 11 is provided with a linear slide rail 12 along the X axis; the bearing platform 21 is arranged on the machine platform 11 for receiving a liquid crystal panel 91, the bearing platform 21 is an air floating platform, which sprays gas upward to The liquid crystal panel 91 is in an air-floating state; the U-shaped frame 31 is erected on the linear slide rail 12, and can be moved along the X axis on the machine table 11 by a driving device. The U-shaped frame 31 has an edge Y A first frame 32 arranged along the X axis, a second fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com