Transmission line wire repair winding device, robot and wire repair operation method

A technology of transmission lines and winding devices, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as high labor intensity, high risk, and long time, and achieve the effects of reducing labor intensity, ensuring personal safety, and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

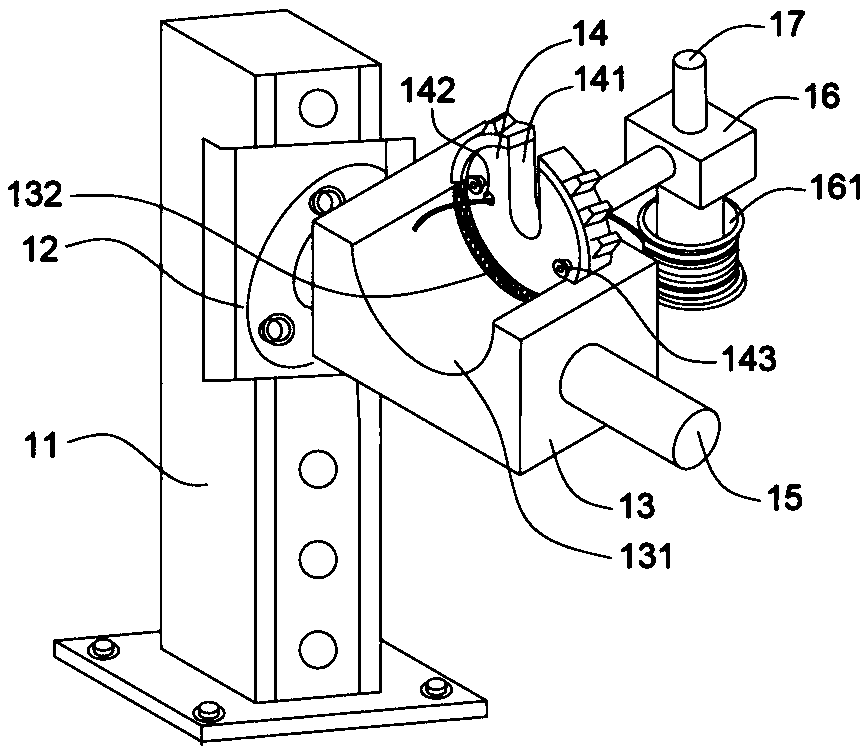

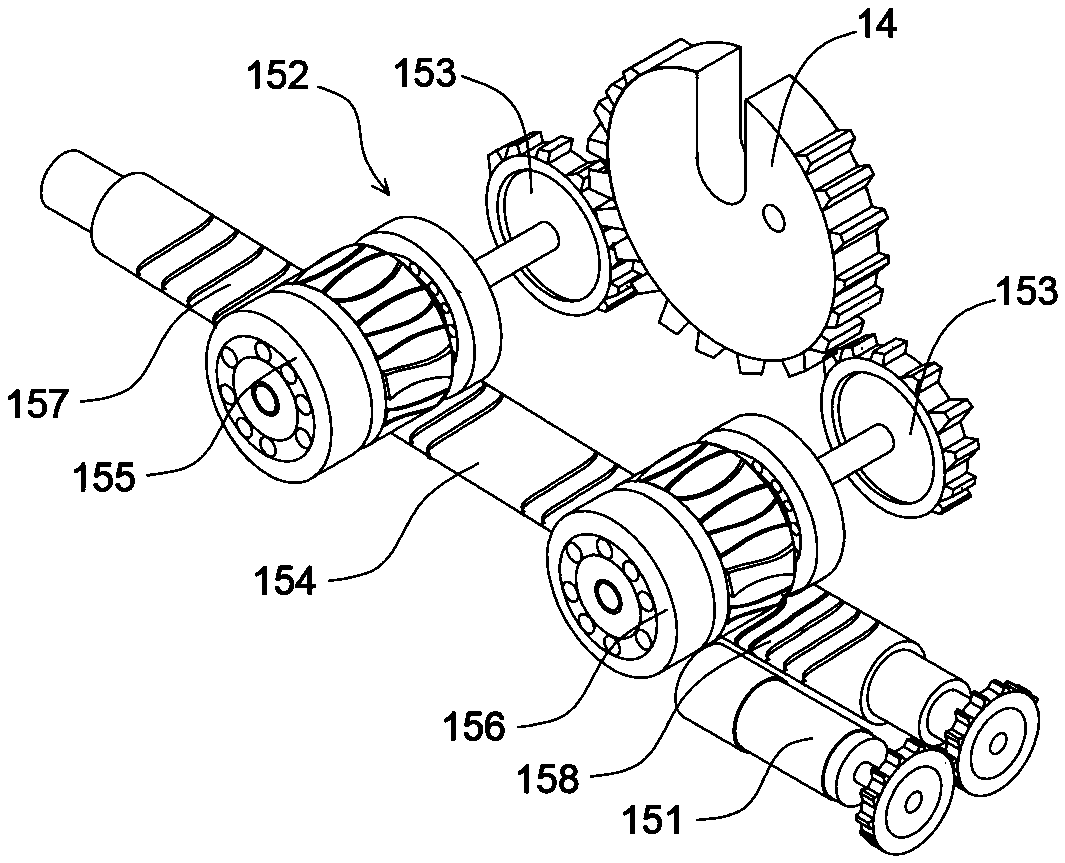

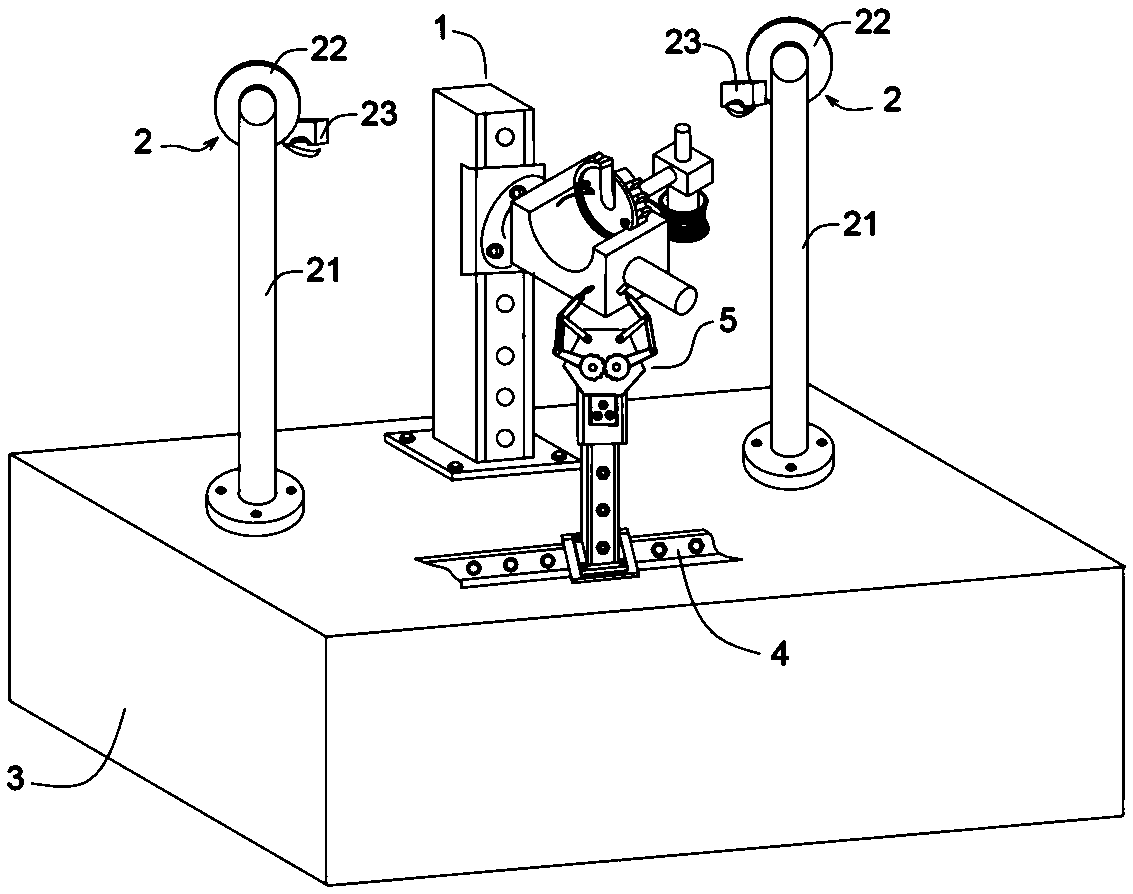

[0033] Such as figure 1 As shown, the power transmission line wire repairing and winding device of this embodiment includes a supporting lifting arm 11, a connecting base 12, and a driving base 13. The driving base 13 is connected to a sliding block supporting the lifting arm 11 through the connecting base 12, and the driving base 13 is provided with There is a spur gear 14 with a wire gripping groove 141, and a threading hole 142 is provided on the side of the wire gripping groove 141 on the spur gear 14, and a winding driving mechanism 15 for driving the spur gear 14 to rotate is provided in the driving base 13, and The driving base 13 is also provided with a support 16, and the support 16 is provided with a winding drum 161 and a pay-off motor 17 for driving the winding drum 161 to rotate. By supporting the lifting arm 11, the connecting seat 12 and the driving base 13 can be raised and lowered, so as to adapt to the wires 7 in different positions. When the wires are repaired...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com