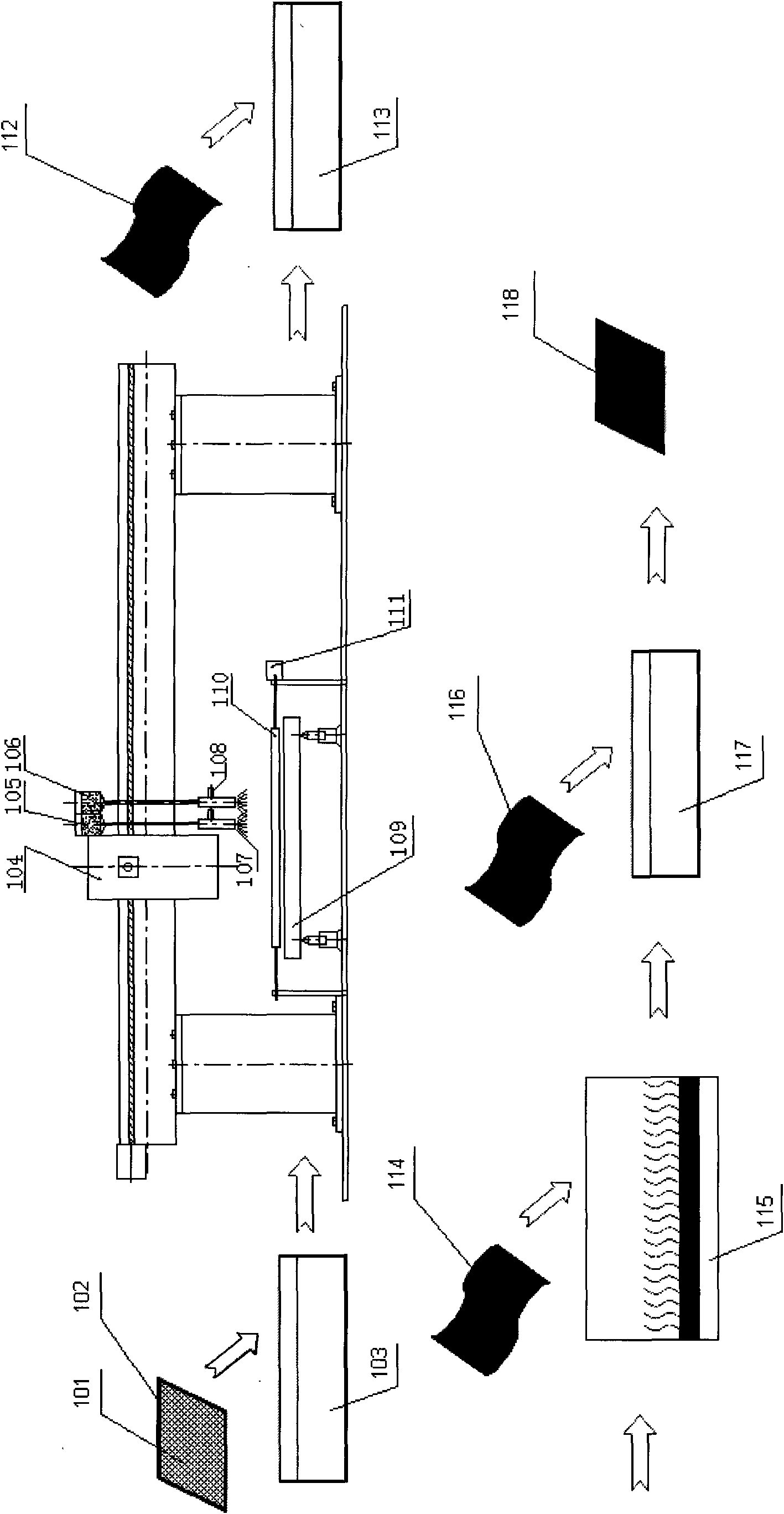

Integrated preparation method for membrane-membrane electrode for fuel cell

A fuel cell and membrane electrode technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of cost reduction, cumbersome routes, disadvantages, etc., and achieve process simplification, cost reduction, and batch manufacturing improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

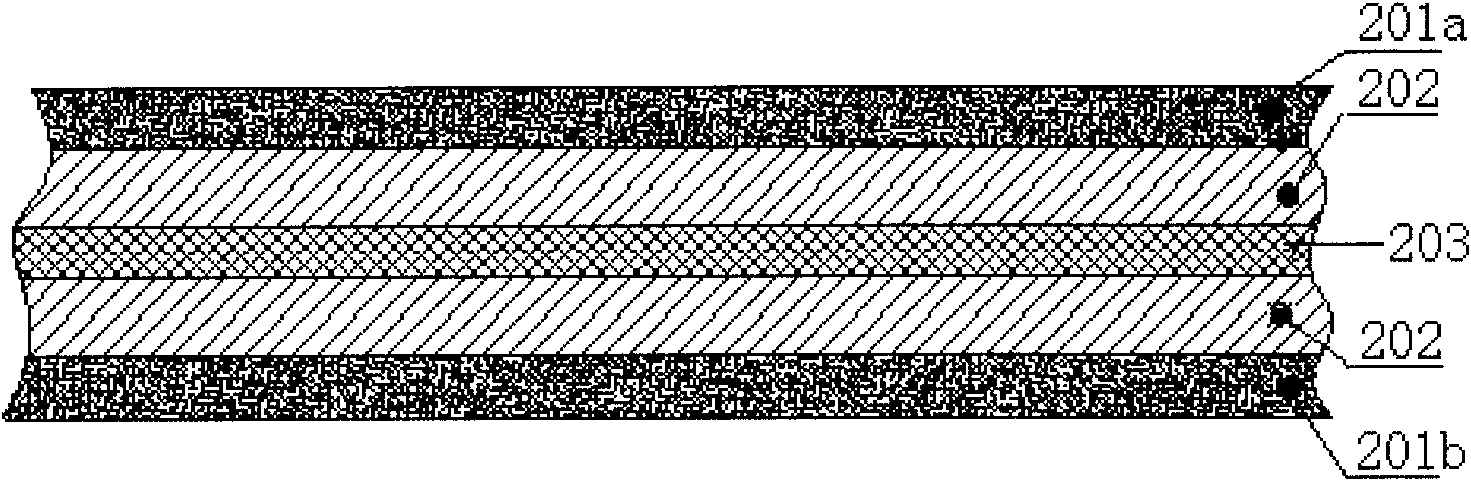

[0056] The membrane electrode is prepared from the proton exchange membrane green body with composite structure, and the specific preparation steps are as follows:

[0057] 1. Preparation of the proton exchange resin solution 105: add a certain amount of N,N-dimethylacetamide to the 5% wt. perfluorosulfonic acid resin solution, vibrate with ultrasonic waves and set aside. The solvent system of the perfluorosulfonic acid resin solution is composed of n-propanol and water, and the mass ratio of N,N-dimethylacetamide to the proton exchange resin solution is 1:1.

[0058] 2. Preparation of proton exchange resin dilute solution 103: dilute 5% wt. perfluorosulfonic acid resin solution to 1% wt. with solvent, and the solvent system is composed of n-propanol and water. A certain amount of N,N-dimethylacetamide was then added and used after ultrasonic vibration. The mass ratio of N,N-dimethylacetamide to proton exchange resin was 2:1.

[0059] 3. Preparation of electrode slurry 106: W...

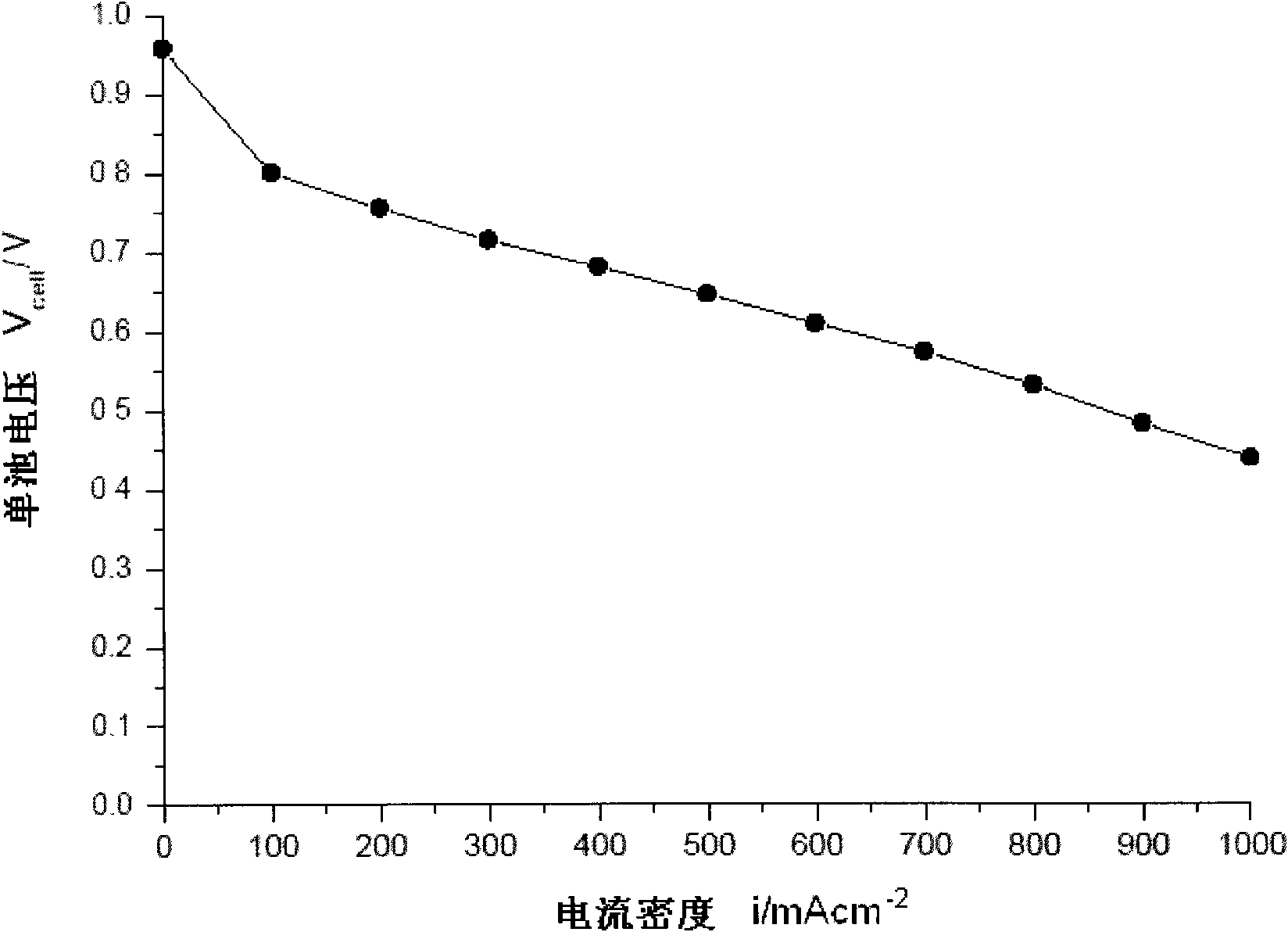

Embodiment 2

[0069] The membrane electrode is prepared by using the proton exchange membrane body with a homogeneous structure, and the specific preparation steps are as follows:

[0070] 1. Preparation of proton exchange resin solution 401: dissolve sulfonated poly(phenylene ether sulfone) in a mixed solvent of N,N-dimethylacetamide and tetrahydrofuran, the content of sulfonated poly(phenylene ether sulfone) is 15%wt., N , the mass ratio of N-dimethylacetamide and tetrahydrofuran is 2:1.

[0071] 2. Preparation of electrode slurry 406: Weigh 40% Pt / C catalyst, 5% wt. perfluorosulfonic acid solution, ethylene glycol and isopropanol dispersant into a weighing bottle, wherein the catalyst and perfluorosulfonic acid The mass ratio of sulfonic acid resin is 3.5:1, the mass ratio of catalyst and dispersant is 1:300, the mass ratio of ethylene glycol and isopropanol in the dispersant is 1:5, and the above materials are placed in an ultrasonic generator for ultrasonic Stir for 30 min to form ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com