Extrusion type juicer

A technology for a juicer and an extruder, which is applied in the field of extruder juicers, can solve the problems of difficulty in extracting juice and rapid oxidation of juice, and achieve reliable crushing effect, increase user satisfaction, and smooth and precise adjustment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

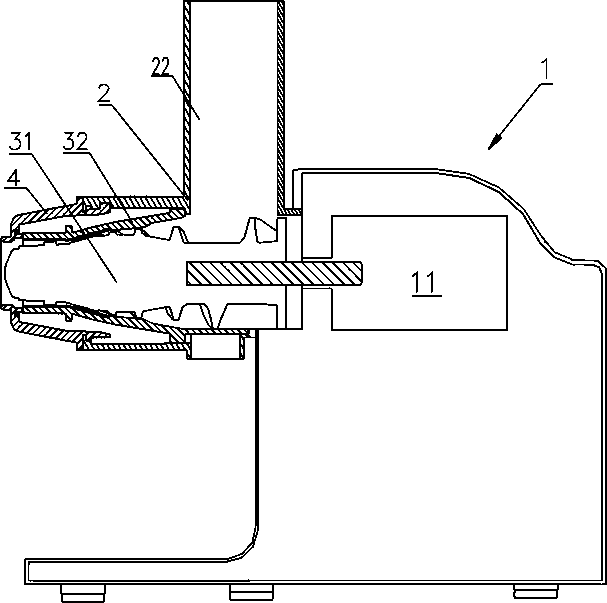

[0036] First, the principle of the present invention is briefly explained. In the present invention, in order to make the extrusion and crushing gap adjustable, a gap adjustment mechanism is provided at the juice collecting chamber or the machine base. When the gap adjusting mechanism is arranged at the machine base, it is used to directly adjust the juice collecting chamber, and then drive the extrusion cylinder, thereby realizing the adjustment of the gap. When the gap adjustment mechanism is arranged at the juice collecting chamber, the extrusion and crushing gap is changed by directly adjusting the extrusion cylinder through the gap adjustment mechanism.

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

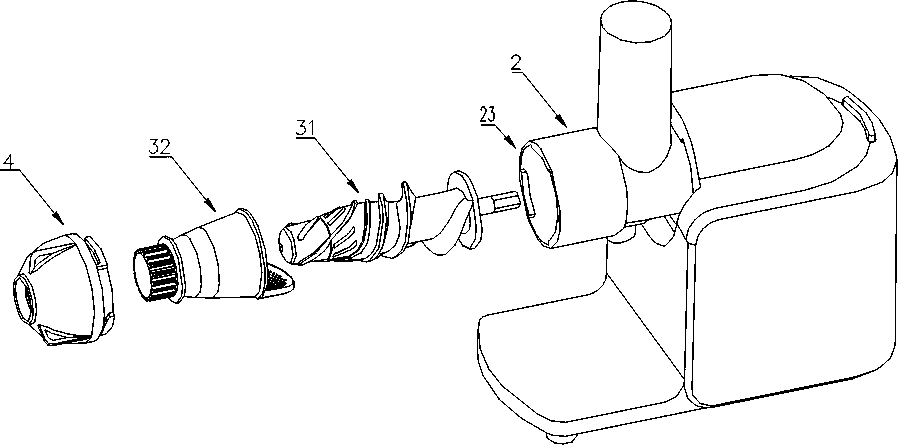

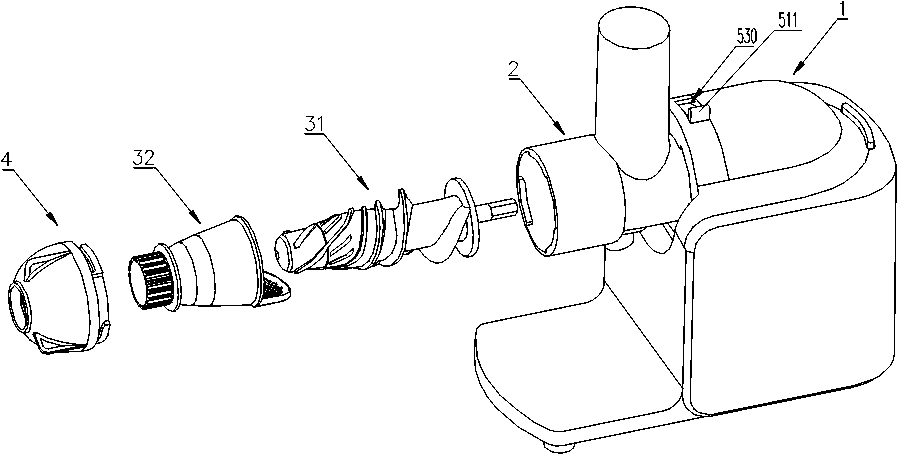

[0038] refer to image 3 , illustrates a perspective exploded view schematic diagram of an embodiment of a squeeze juice extractor of the present invention. As shown in the figure, also refer to Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com