Energy-saving hot filling auxiliary device

An auxiliary equipment and hot filling technology, which is applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of low production efficiency and cost increase, and achieve the effect of reducing weight, reducing raw material costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

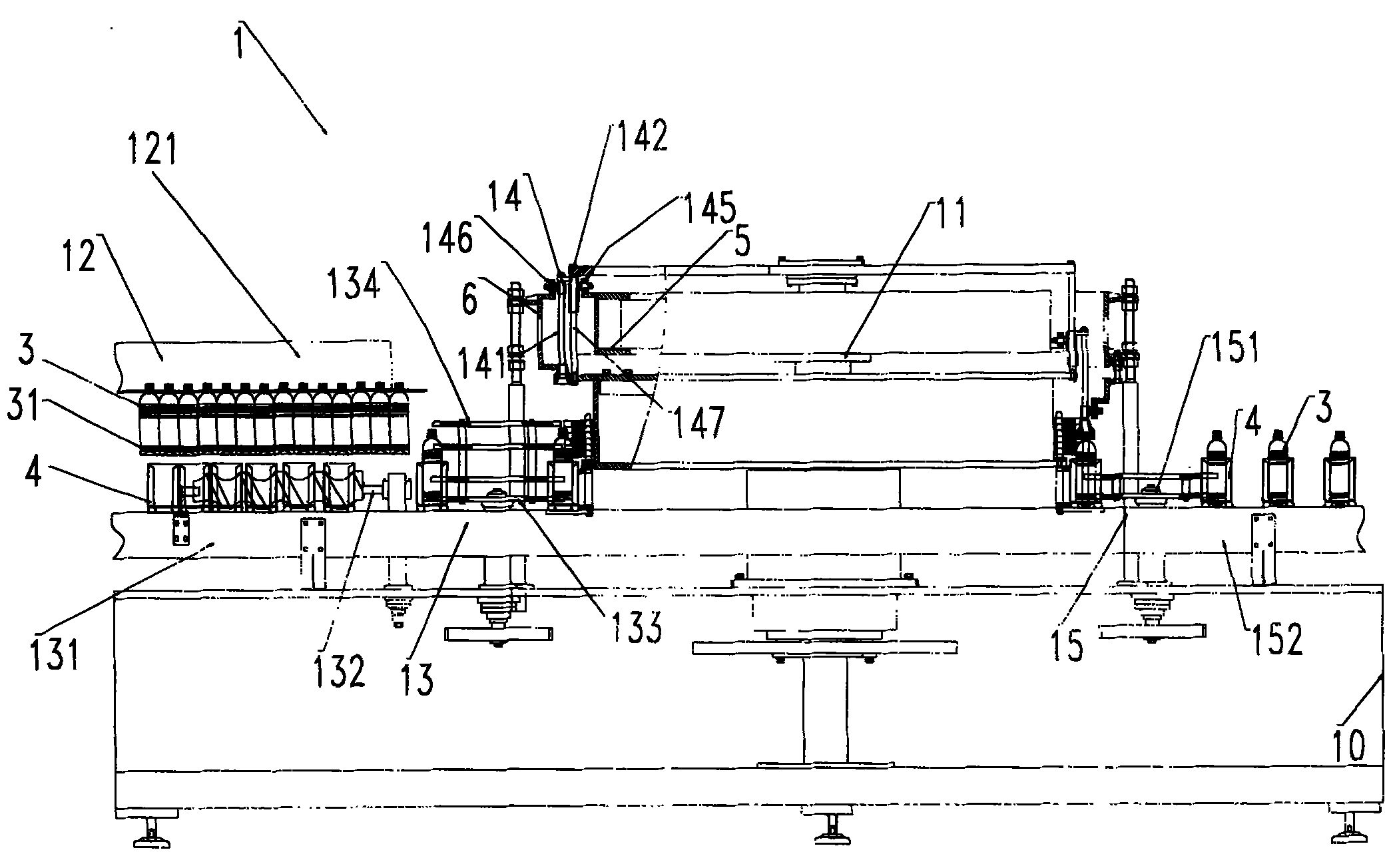

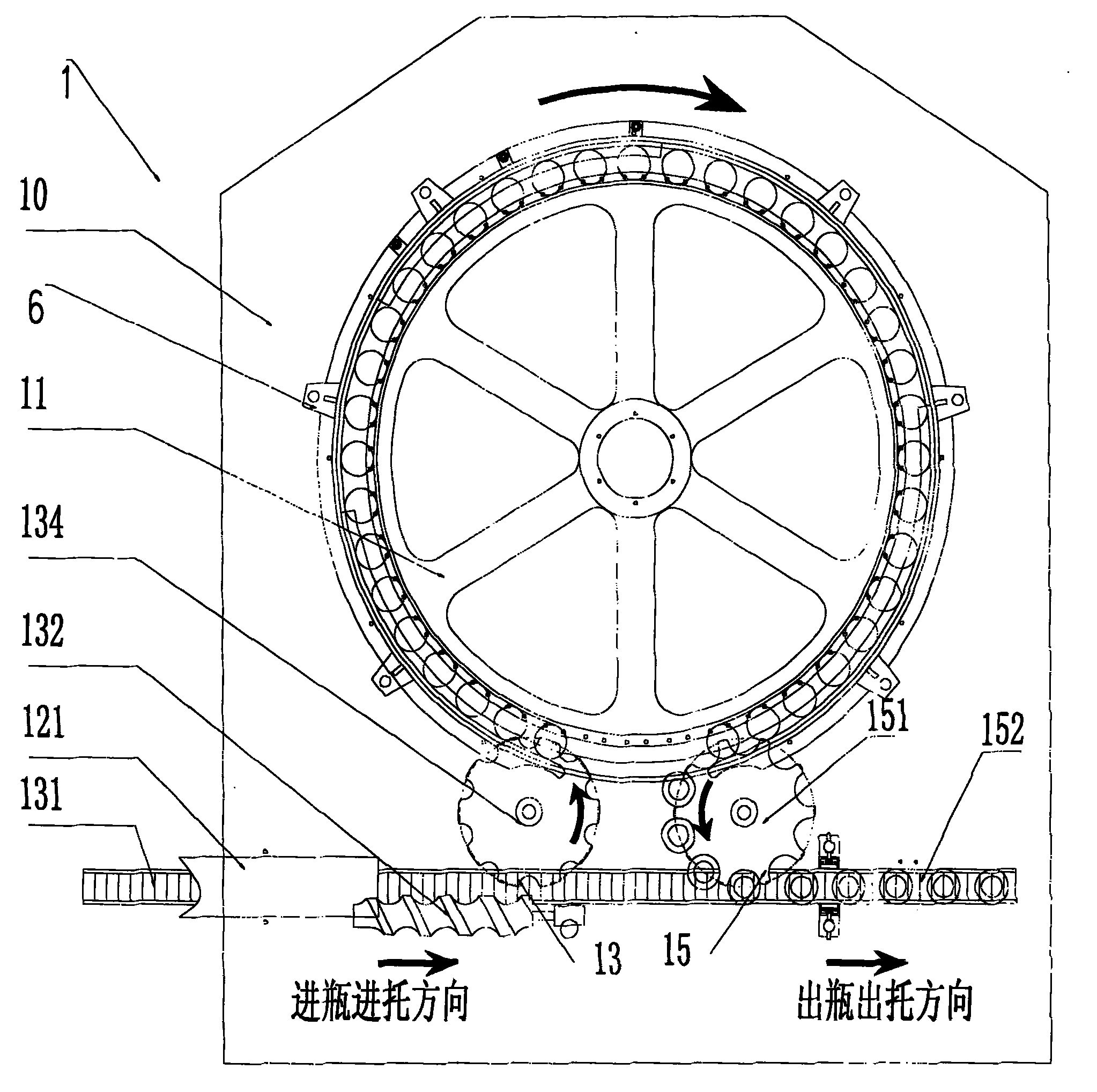

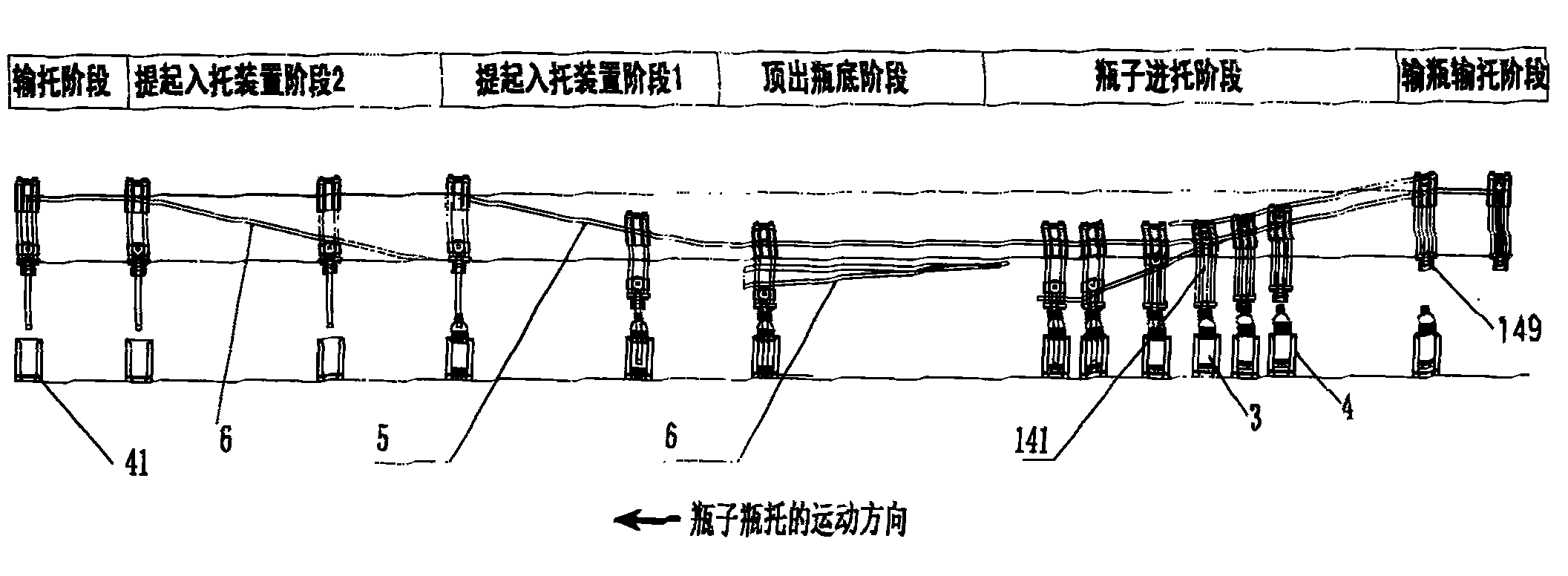

[0023] see Figure 1 to Figure 3 As shown, an energy-saving hot filling auxiliary equipment includes a tray-in machine 1 and an unloader 2 respectively arranged on the tray-in frame 10 and the tray-out frame 20, the tray-in machine 1 includes a tray-in machine rotating body 11, Transport the bottle holder 4 to the first star wheel transmission mechanism 13 in the rotating body 11 of the tray loading machine, and transport the bottle 3 with the inward bubbling 31 at the bottom of the bottle to the air feeding input bottle mechanism on the first star wheel transmission mechanism 13 12. The air-feeding input bottle mechanism 12 is arranged directly above the first conveying chain 131 of the first star wheel transmission mechanism 13, and the bottle 3 and the bottle holder 4 are placed on the first star wheel transmission mechanism 13 The top is in the position of upper and lower alignment; the inner cam 5 and the ejection device 14 for pressing the bottle 3 into the bottle holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com