Deep ground stress measurement while drilling (MWD) system

A test system and stress test technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of time-consuming and long time, and achieve the effect of high efficiency, simple operation and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

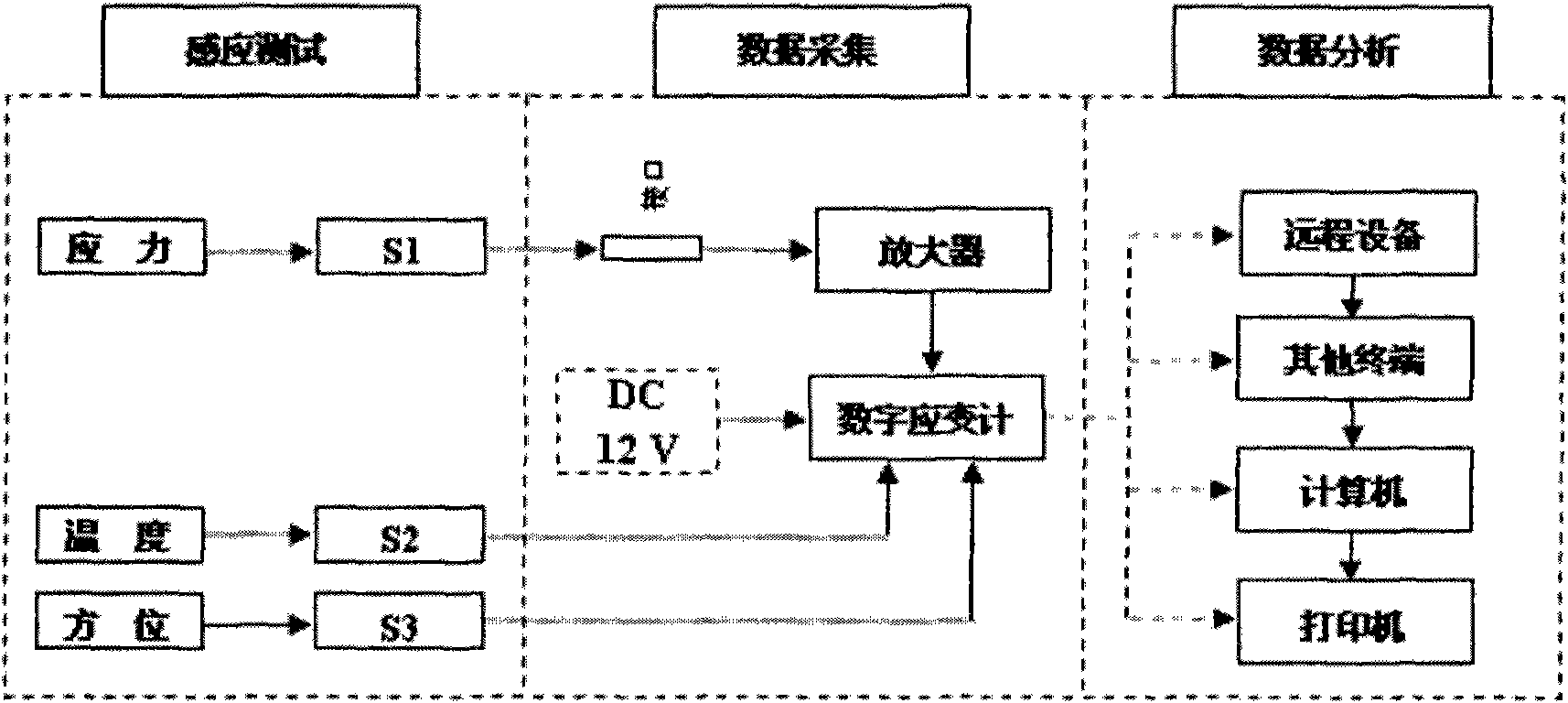

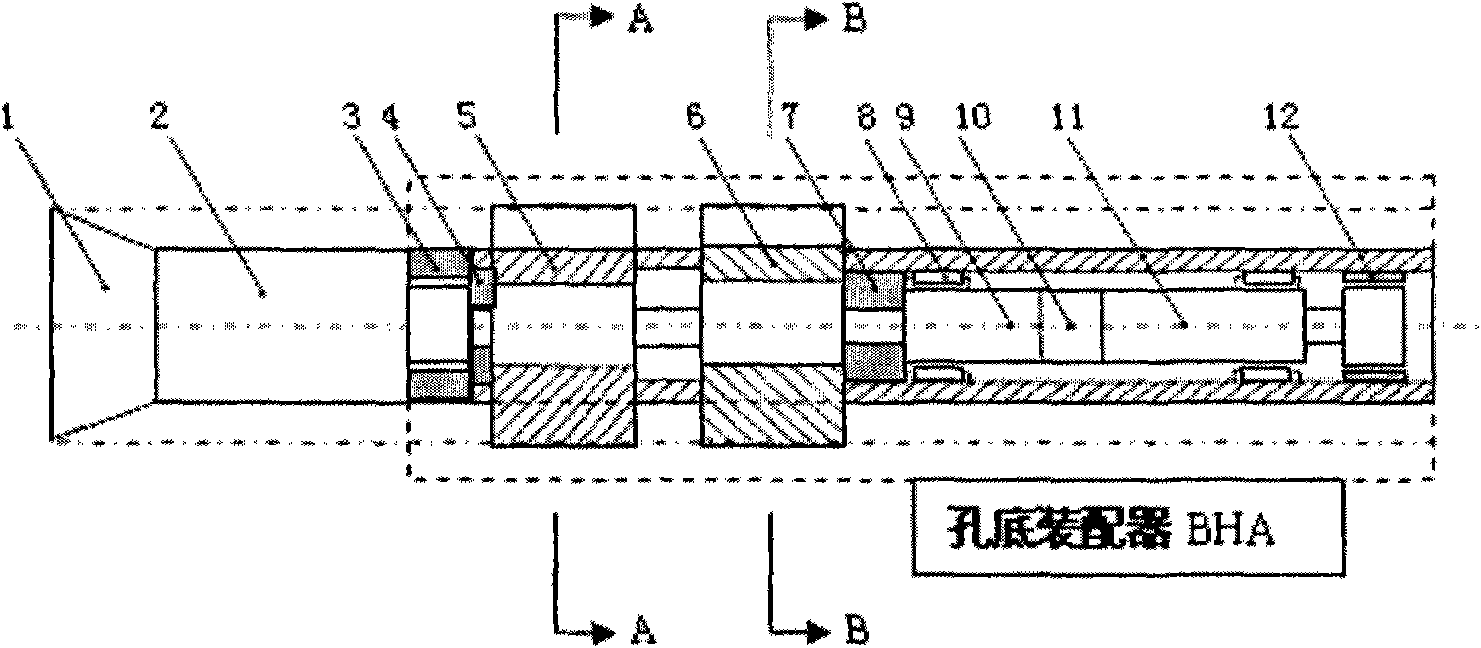

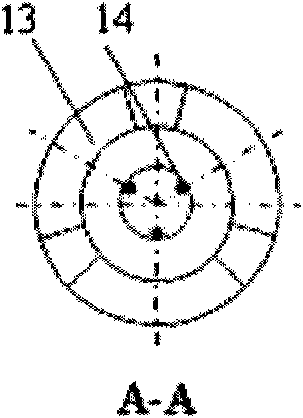

[0038] like figure 1 Shown is a system structure diagram of a deep ground stress while drilling testing system of the present invention, the system includes an induction testing unit, a data acquisition unit and a data analysis unit;

[0039] The induction test unit includes a stress sensor S1 for testing the ground stress in the borehole. Because the stress level in the earth's crust is closely related to the historical tectonic movement and geological conditions, the stress level is different in different geographical locations and different sounding depths. Therefore, the stress sensor will measure for different stress levels. In the present invention, the stress sensor is designed as two groups of synchronous stress testing units of high ground stress and low ground stress, and each group respectively measures the stress and strain at three equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com