Bearing pedestal for cooling fan

A cooling fan and bearing seat technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc. It can improve the reliability and service life of the work, and achieve the effect of smooth and smooth rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

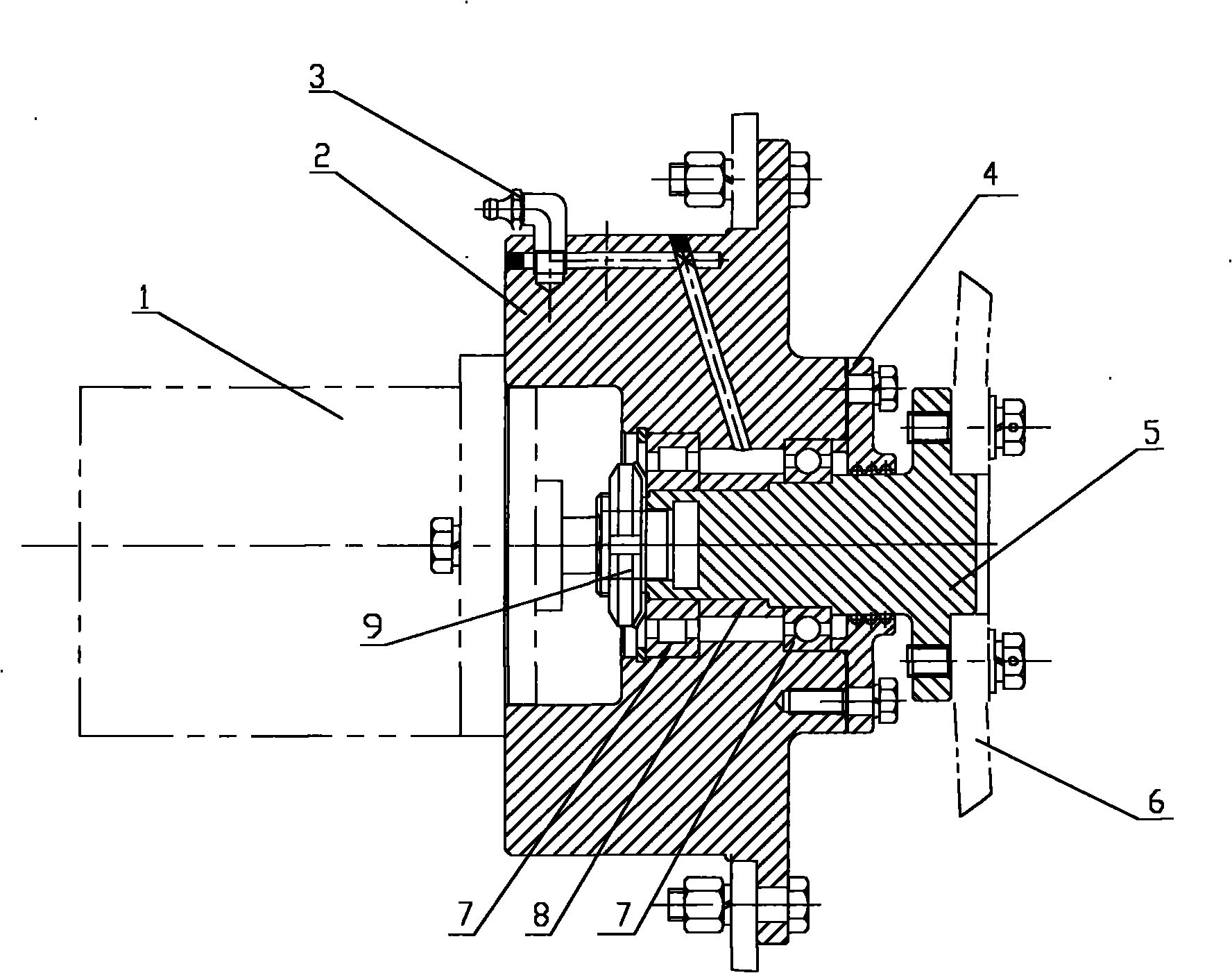

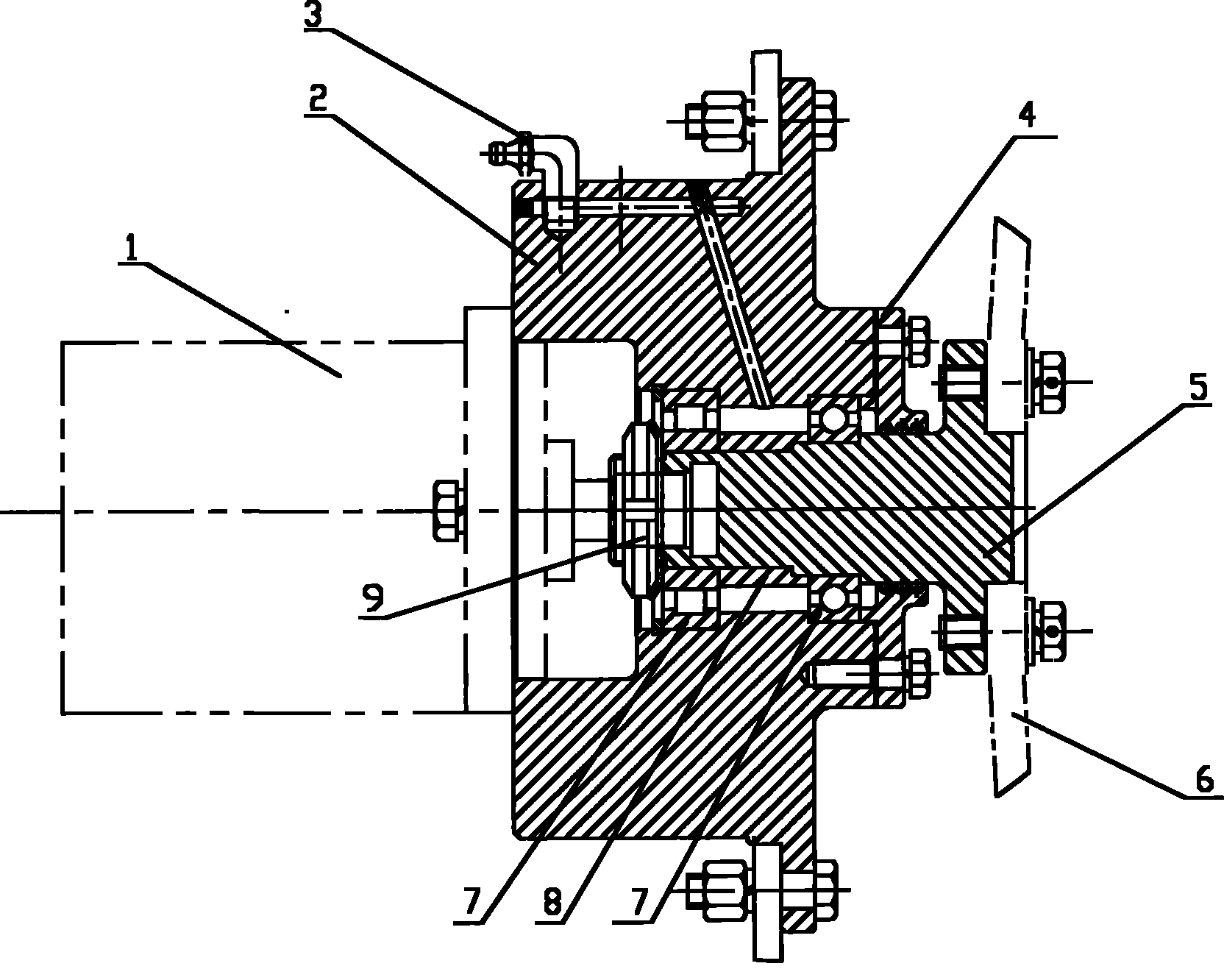

[0014] Attached below figure 1 The specific embodiments of the present invention are described in detail: figure 1 In the cross-sectional view of the bearing housing for cooling fan shown, the bearing housing for cooling fan consists of hydraulic motor 1, bearing housing body 2, oil cup 3, sealing cover 4, transmission shaft 5, cooling fan mounting seat 6, rolling bearing 7, and positioning ring 8. It is composed of 9 stop washer, no welded structure, and totally dependent on structural connection.

[0015] The input end face of the bearing housing body 2 is directly fixed on the hydraulic motor 1 driving the cooling fan, and the contact surface is sealed to prevent the lubricating oil in the oil cavity from leaking.

[0016] The input end of the transmission shaft 5 is keyed to the drive shaft of the hydraulic motor 1 that drives the cooling fan, and the output end of the transmission shaft 5 is connected to the cooling fan through the cooling fan mounting seat 6. The input end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com