3-D impeller of high-load centrifugal compressor

A technology of centrifugal compressor and ternary impeller, which is applied to pump components, mechanical equipment, machines/engines, etc., and can solve problems such as restricting advancement, friction loss, boundary layer separation loss, shear mixing loss, and insurance factor weight gain. , to achieve the effect of meeting the structural strength requirements, ensuring dynamic performance, and inhibiting the development of thickening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The ternary impeller of the present invention will be described in detail below in conjunction with the accompanying drawings.

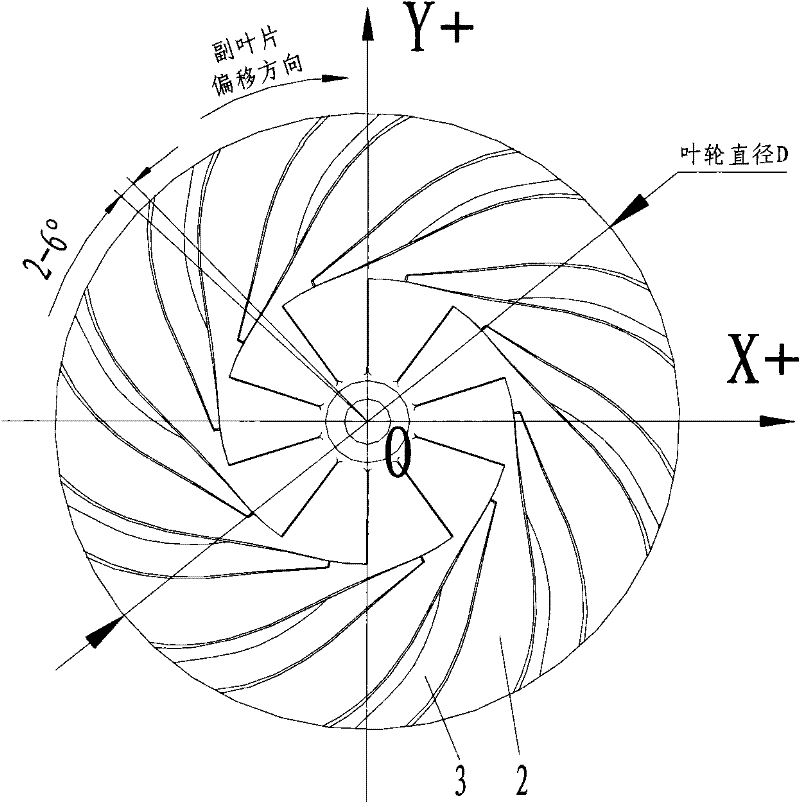

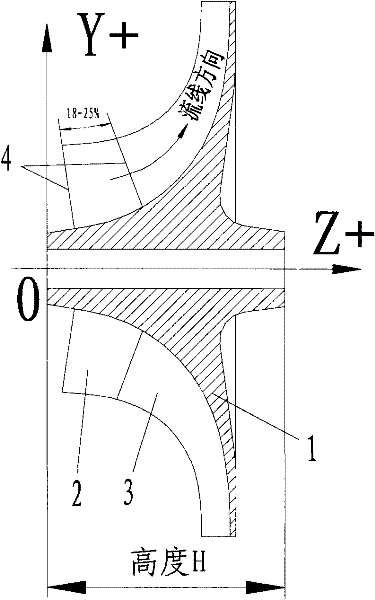

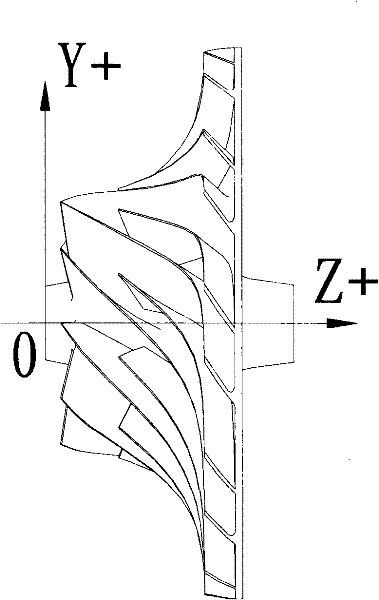

[0024] Such as Figure 1-3 As shown, the three-dimensional impeller of the high-load centrifugal compressor of the present invention includes a back plate 1 and three-dimensionally curved and twisted main blades 2 and auxiliary blades 3 whose surfaces are radially distributed around the center of the impeller, 10 main blades are uniformly distributed around the center of the impeller, and 10 The auxiliary blades are located between two main blades 2, and each auxiliary blade 3 is offset by 2-6° along the impeller rotation direction based on the circumferential center of the two main blades 2. At the position of 18-25% of the line direction, the front edges of the main and auxiliary blades are both arc-shaped, and the spatial shapes of the corresponding parts of the main and auxiliary blades are adapted.

[0025] The following is a specific sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap