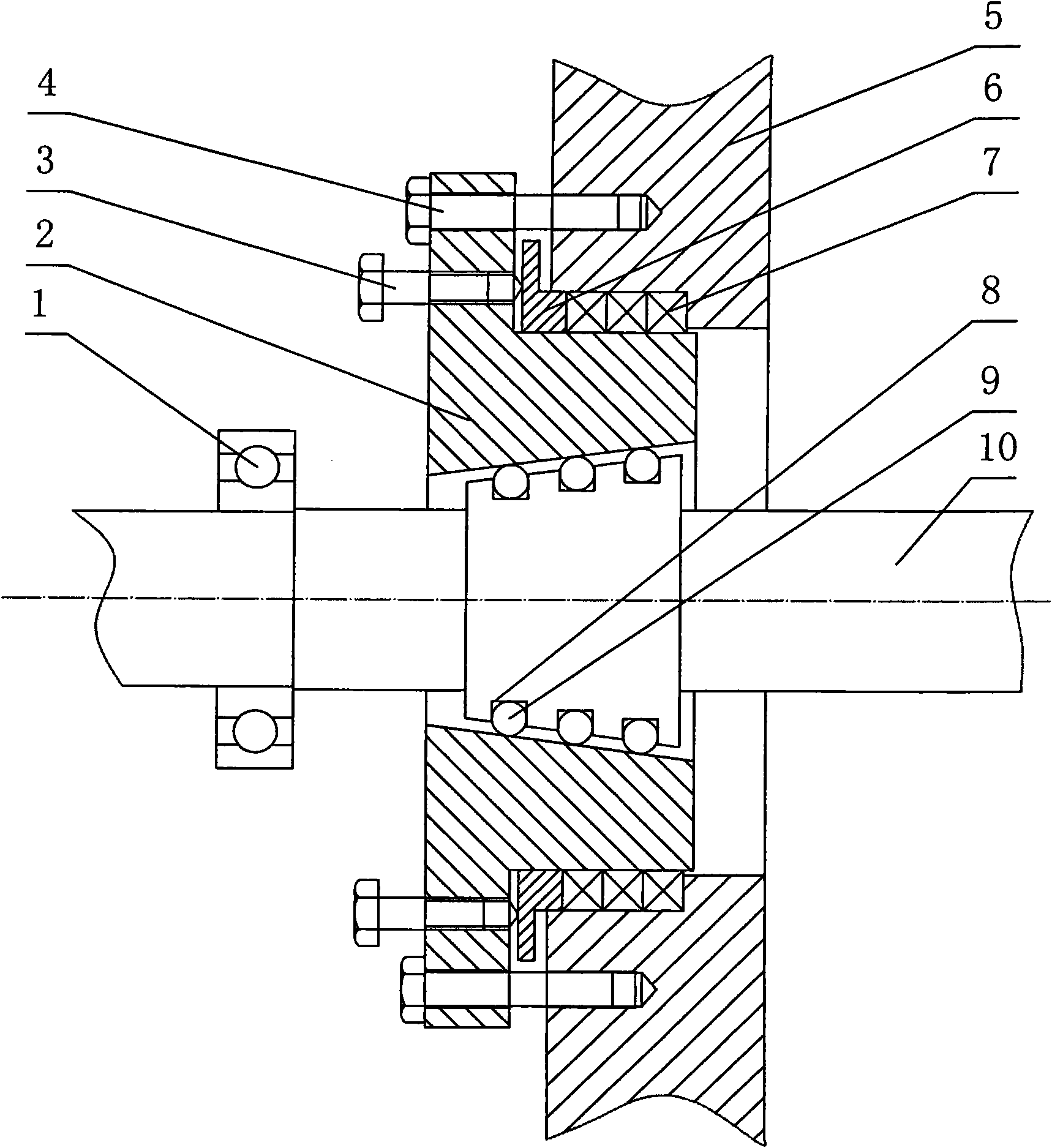

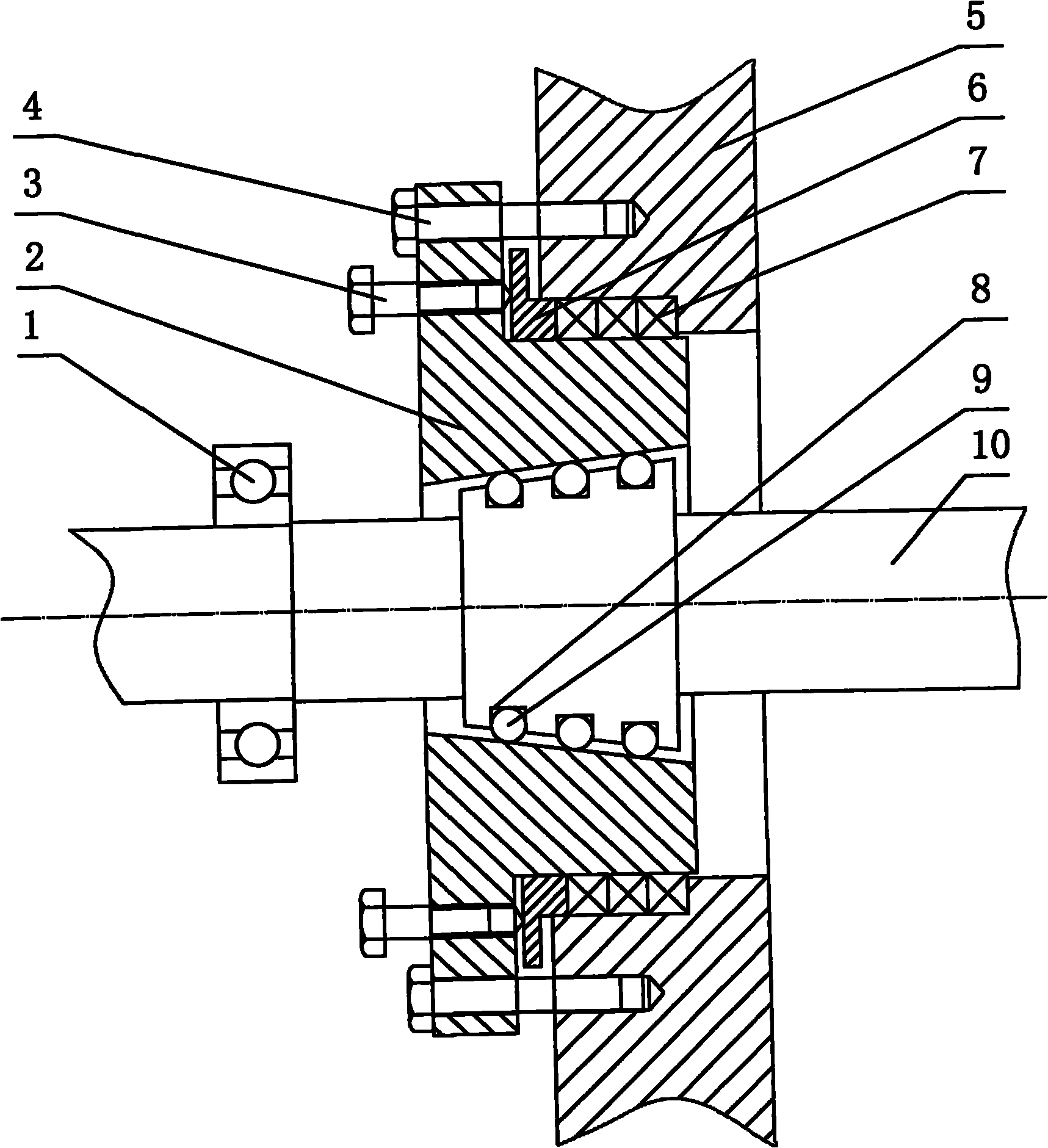

Dynamic seal structure of screw shaft of underwater pressure-bearing shell

A technology of dynamic sealing structure and pressure-bearing shell, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of the applicability of underwater pressure-bearing shells, etc., to reduce the contact area and achieve reliable sealing , the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] As shown in the attached figure, it is an underwater pressure-bearing shell. The stern shaft is connected with the motor in the pressure-bearing shell through bearings and couplings, and the other end of the stern shaft is connected with the propeller through keys and couplings. It is required to install the sealing device. When the motor starts and the propeller works, the sealing system starts to work normally. After working for a period of time, it is found that there is a small amount of leakage on the dynamic sealing surface. At this time, there is no need to stop the machine. Use tools to gently tighten 45-90 degrees one by one according to the relative adjustment bolts, and work in this way in the future. When the tightening bolts cannot be further tightened, it means that the adjustable sealing seat has been adjusted to the limit position, and the sealing ring needs to be replaced if leakage occurs again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com