Material flow device

A material flow and material technology, applied in furnaces, shaft furnaces, vertical furnaces, etc., can solve problems such as safety accidents, gas leakage, etc., achieve high safety, prevent gas leakage, and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

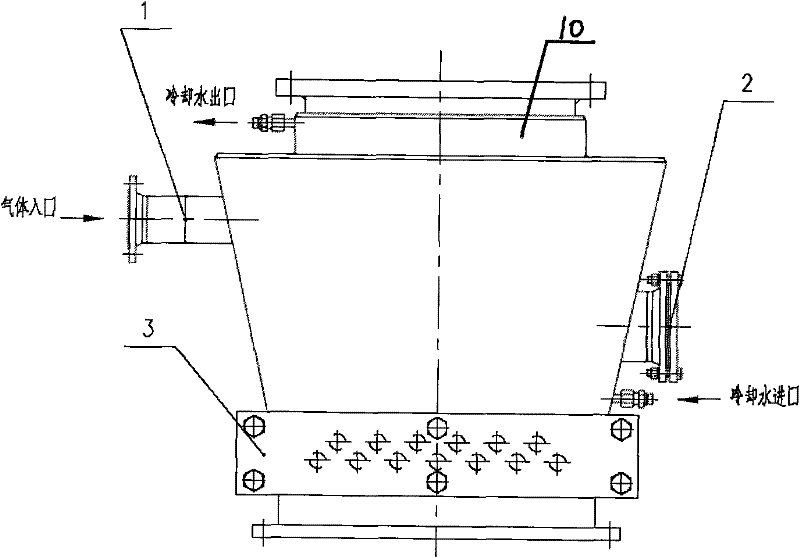

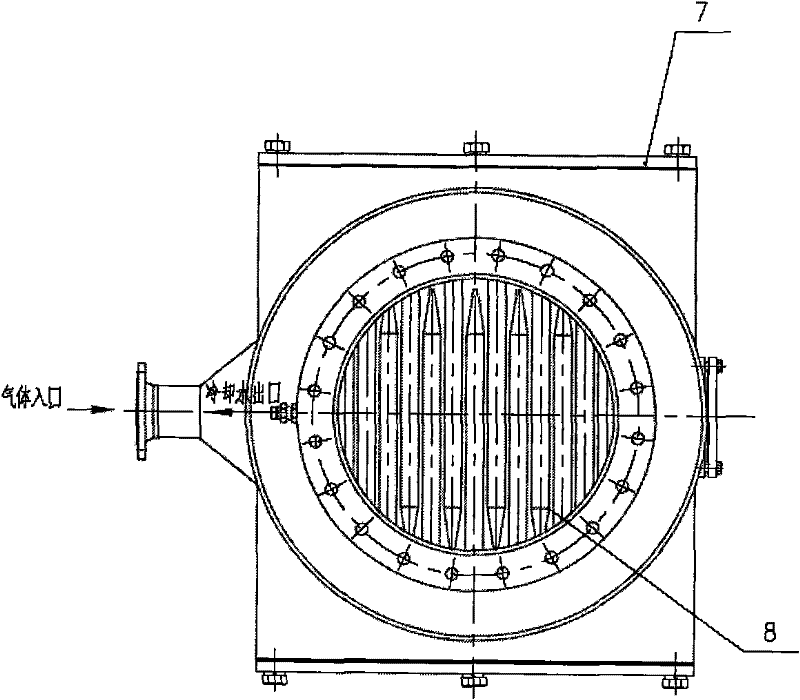

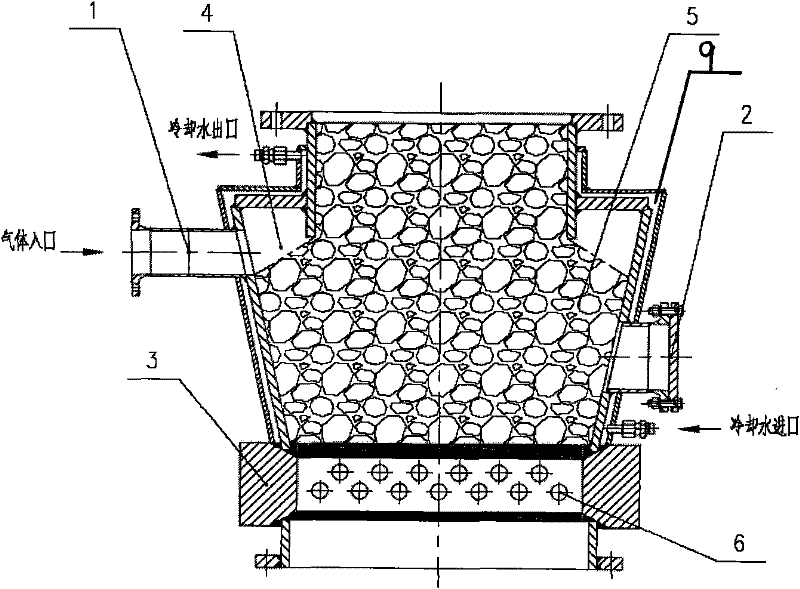

[0018] Such as figure 1 , figure 2 , image 3 as shown,

[0019] A material flow device, comprising a gas inlet pipe 1 arranged on the side of the gas seal section, the upper surface of the gas seal section is provided with a material inlet 10, the size of the material inlet 10 is smaller than the size of the upper surface of the gas seal section, the gas seal section The lower part of the sealing section is connected with a material cutting part 3 having a pinhole 6, and the two end faces of the material cutting part 3 are also provided with end face sealing covers 7. The device can be used in the normal pressure or low pressure reduction shaft furnace, the furnace top charging system or the furnace bottom discharge system. It plays a sealing role for the escape of reducing gas inside the equipment, and can also cut off the material during the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com