Microscope lens device with light guide function

A technology of microscope head and light function, applied in microscopes, optics, optical components, etc., can solve the problems of affecting the clarity of observation, the combination of light sources showing its three-dimensional shape, and the lack of suitable structure for general products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation and structure of the microlens device with light guiding function proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

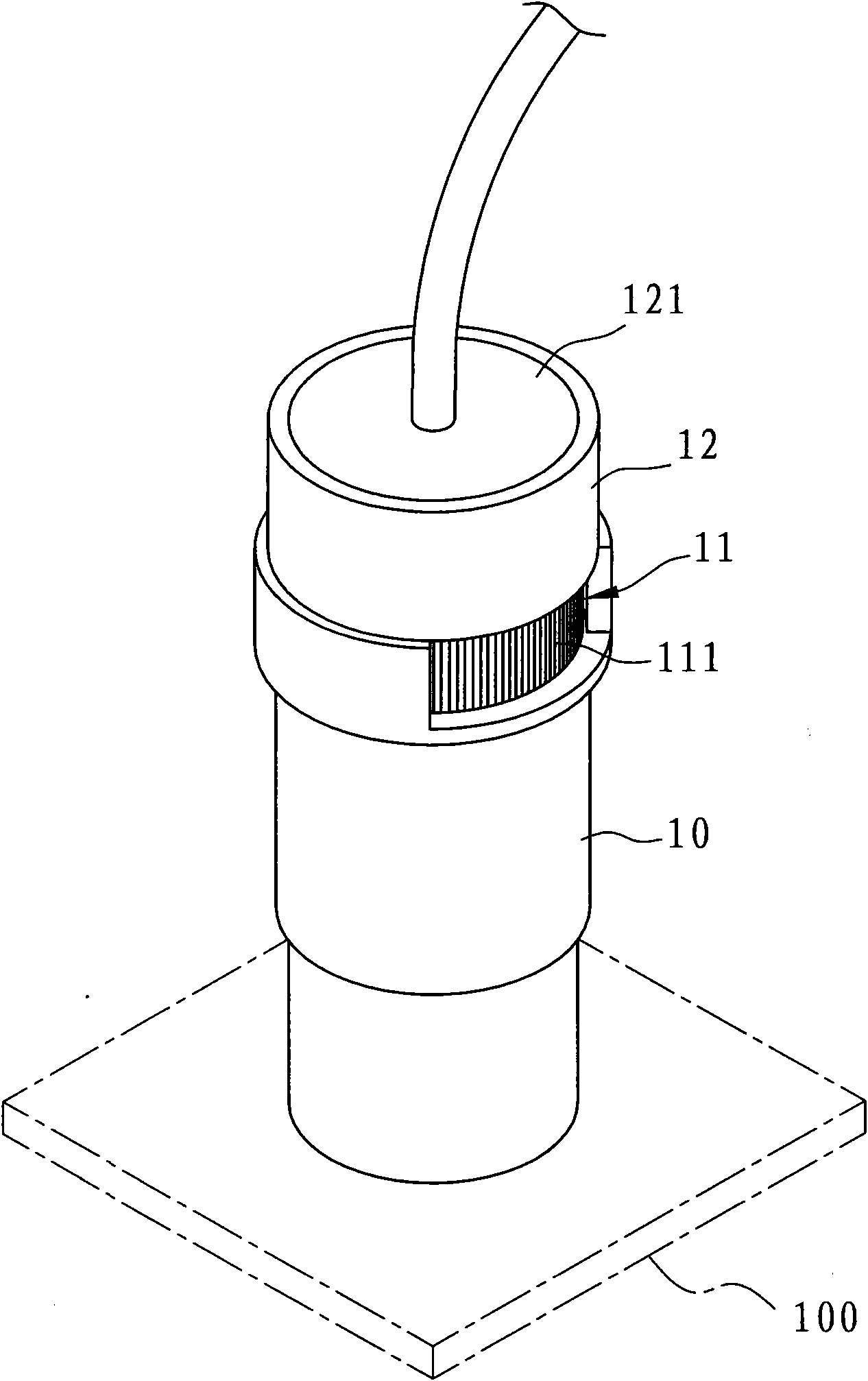

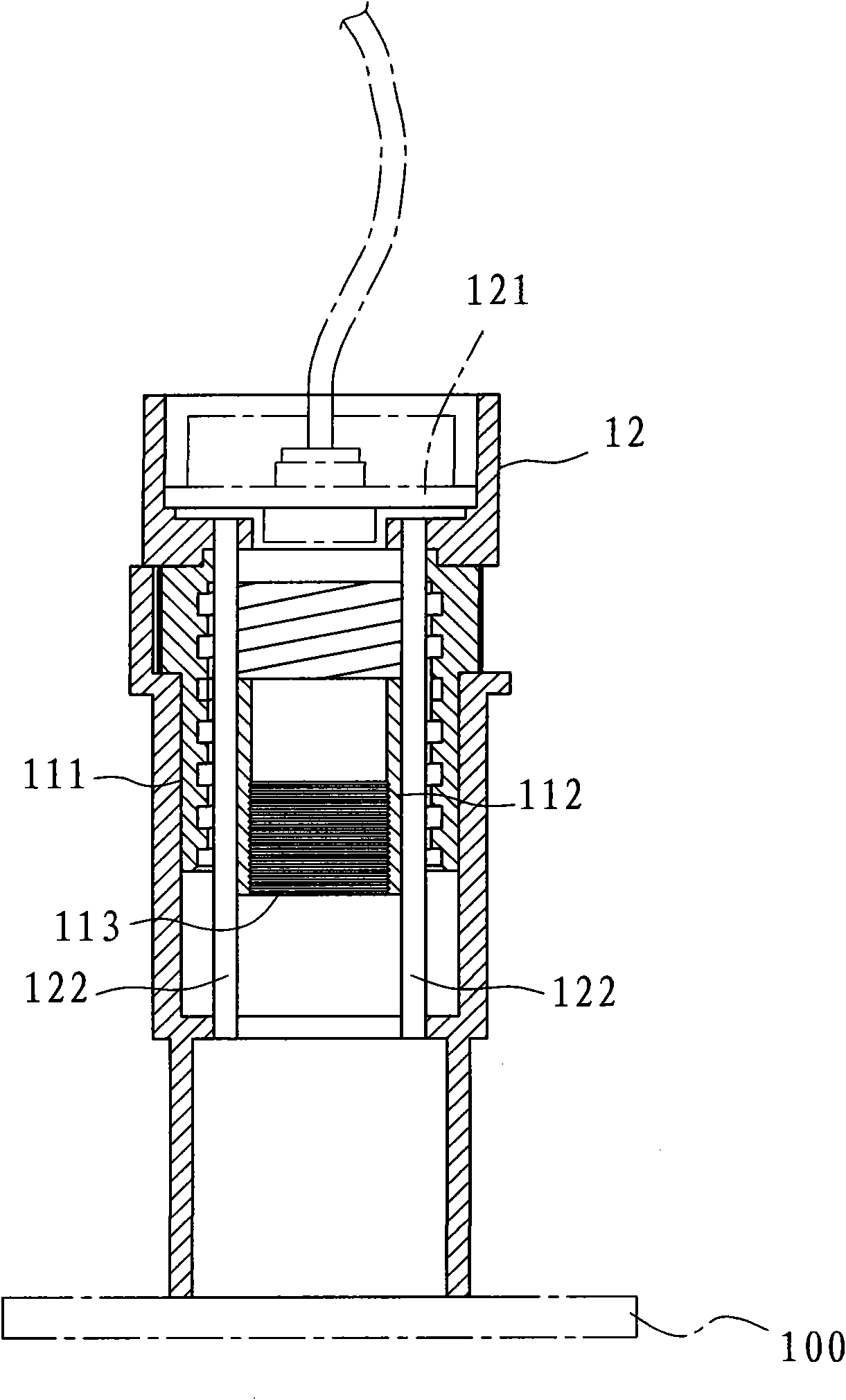

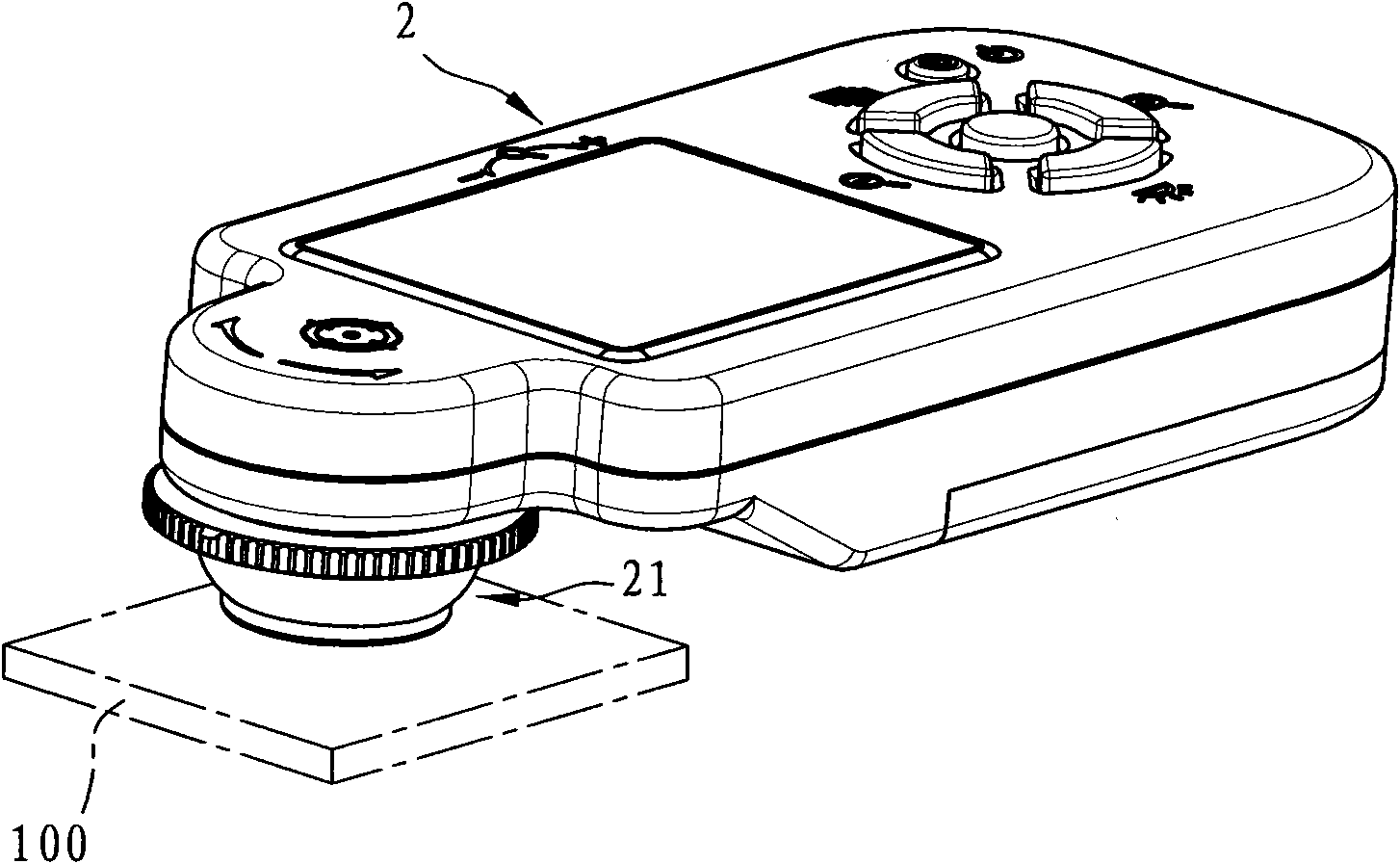

[0031] see Figure 5 , Figure 6 , a preferred embodiment of the microlens device with light guiding function of the present invention is used for microscopic magnification observation of an object to be measured 200, the microlens device includes: a base 3, an observation unit 4, a plurality of light emitting Component 5 , a sleeve unit 6 , a light guide cover 7 and a control unit 8 .

[0032] The observation unit 4 is disposed on the base 3 and used for amplifying the observed image of the object under test 200 . In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com