Processing box

A technology for processing boxes and casings, which is applied in the field of processing boxes for laser printers, and can solve problems such as affecting printing quality, insufficient blackness of text or patterns, and low toner electric field force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

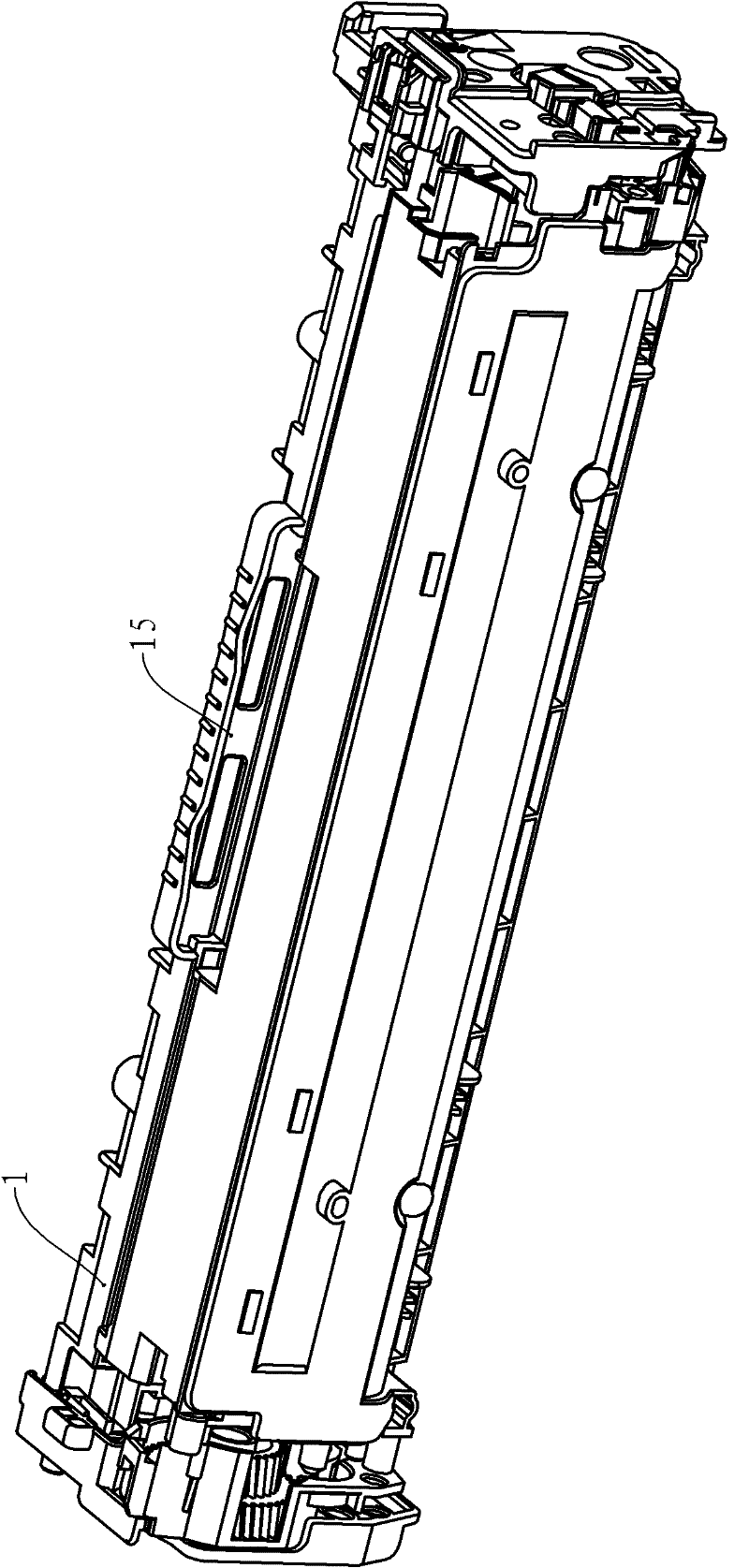

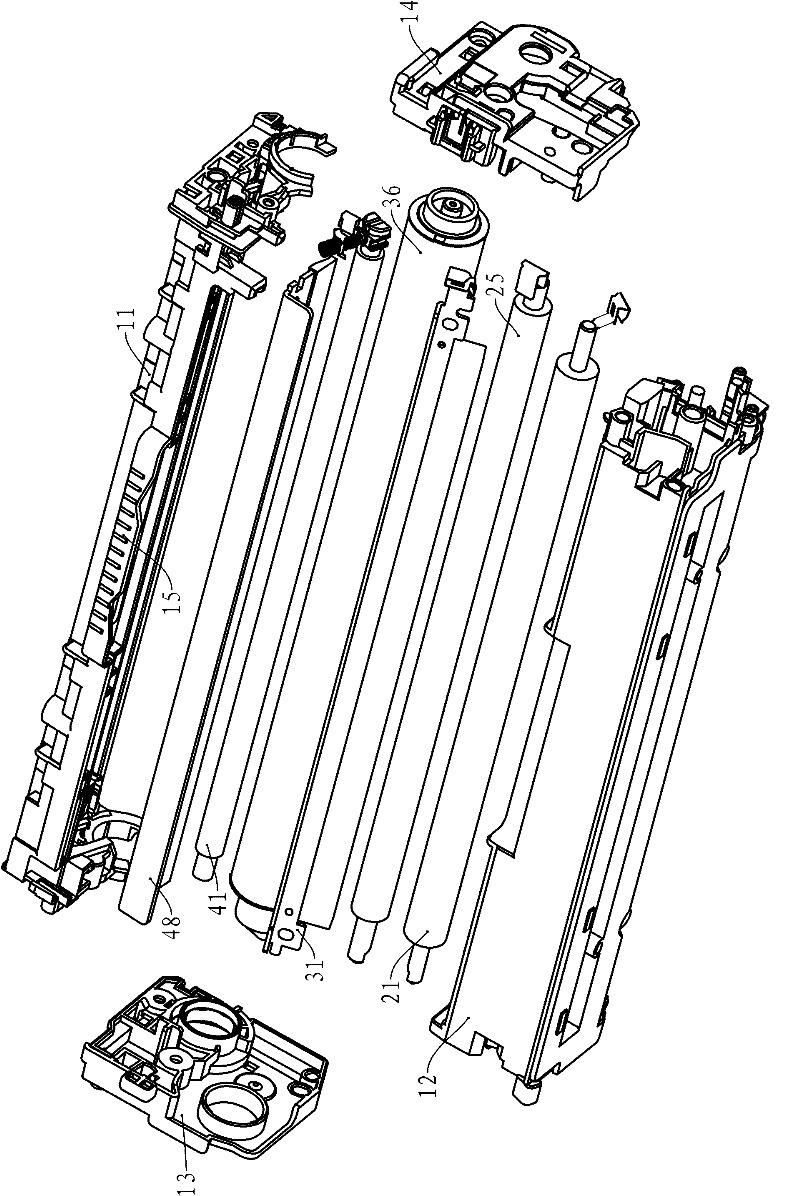

[0034] The process cartridge according to the present invention has a housing, which is composed of a drum frame, a toner cavity frame and two end covers, and the toner cavity frame has a toner cavity for accommodating toner, which is the same as the existing process cartridge.

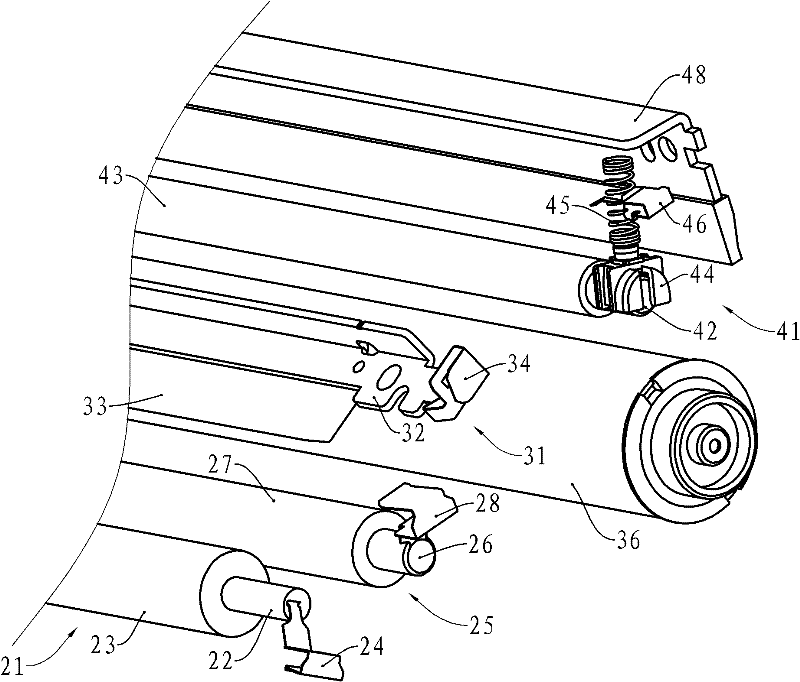

[0035] Inside the shell, the processing box is provided with a powder feeding roller, a developing roller, a powder discharging knife, a charging roller, a photosensitive drum and a cleaning blade. The structure of the above components is as follows Figure 5 Shown.

[0036] The powder feed roller 51 has a mandrel 52 made of metal, the mandrel 52 is wrapped with an elastic layer 53, and one end of the mandrel 52 is connected to the conductive sheet 54 to receive the voltage of the laser printer. Similarly, the developing roller 56 also has a core shaft 57, the core shaft 57 is wrapped with an elastic layer 58, and one end of the core shaft 57 is connected to the conductive sheet 59 to receive the voltage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com